Trane® Saves Over 80 Hours of Robot Programming Time

Their biggest challenge and opportunity for automation was the manual, labor-intensive tube rolling process. Because each chiller was a customized product, there was no single standardization to the hole patterns-adding to the complexity of a potential automation process.

Robot-based Automation: 3 Tips for a Time and Cost-efficient Implementation

Following the no-code/low-code trend, there are various software solutions on the market that enable graphical and therefore simplified and faster programming. The advantage is that no special programming skills are required.

How Simulation Can Secure Your Robotics Investment

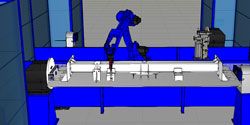

Robotics simulation can be defined as a digital tool used to engineer robotics-based automated production systems. Essentially, robot simulation employs a digital representation to enable dynamic interaction with robot models and machines in a virtual environment.

General Purpose Programming Languages Are the Future for the Industrial Automation Industry and Are Overtaking Traditional PLC IEC 61131-3

IEC 61131-3 is the de facto standard in the industrial automation industry. It encompasses 5 different programming "languages". It makes designing simple programs straightforward and easy, and it does this very well.

Fuzzy Logic and CAIRE, on the Way to Automating the Painting Process

Fuzzy Logic Repplix software module allows a robotic system to learn trajectories in a single gesture without any specific training. With the help of a portable learning device, an operator can transfer their professional know-how to the robot by simply executing their task.

How Simulation Enhances the Offline Programming Experience

One of the strengths of offline programming (OLP) software is that it combines two powerful capabilities: simulation and programming. These two capabilities fit together like two perfect puzzle pieces when it comes to effectively programming robots offline.

The Next Big Thing in Manufacturing: XaaS to Boost Productivity and Revenue

The traditional portfolio mix of heavy hardware-orientation with associated software is transitioning to application and non-control software. The move to solutions combining hardware, software, and services is real.

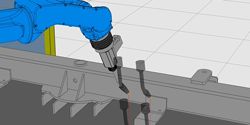

Making Robotic Programming Easier for the Fabrication Industry

OLRP provides a virtual environment to complete robot programming without taking the robot offline, thereby simplifying complex and time-consuming programming.

Fuzzy Logic Makes Robotics Agile at MBDA

The company wanted to robotise certain processes in small series or even single unit production, by allowing an operator with no programming skills to teach the robotic system, in just a few seconds.

Big Trends in Offline Programming Software for Robot

In the world of robotics, Offline Programming (OLP) has come a long way in a short time, and the global pandemic has jumpstarted more innovation. Industrial robots have evolved to collaborative robots ("cobots") that work side by side with their human counterparts.

The Future of Robot Programming - Industrial Robot Programming Tool Supports All Phases of Automation

Self-sustainability means, of course, that the working systems between robots and humans can continue to function, and grow, into the future. Indeed, for manufacturers a key signifier of growth is acquiring more machines that also have more capabilities.

Calculating the ROI of Offline Robot Programming Software

Capital investments in advanced manufacturing environments require careful consideration, especially if that investment is for a new process or technology. If you are looking at investing in OLP here are some things to consider about the potential return on investment (ROI).

Is your OLRP Implementation Process SMART?

For any Offline Robot Programming solution to be effective, the virtual robot cell set up in the software must be identical to the existing physical robot cell. OCTOPUZ refers to this process as "implementation".

Robot Control: Using Native Programming Language or an External Controller?

In service robotics as well as in academia, flexibly designable, use-case specific controllers are used, resulting in the respective robots to mainly act as actuators with low-level control systems but without individual intelligence.

Democratising Automation - the Benefits of No-code Robotics

The so-called 'no code' revolution in programming seeks to make the automation industry more autonomous and to democratize the use of robotics at the shop floor level.

Records 1 to 15 of 84

Featured Product

The piCOBOT Electric vacuum generator

Fully electric, slim design and absence of air-tubing and cabling. The new piCOBOT® Electric heads towards another success for Piab's piCOBOT® program. A secondary effect of these achievements is the absence of entangling air tubing and cabling. It simplifies the installation, and as the new piCOBOT® Electric only needs a single connection on the cobot arm, the clean set-up allows a completely unrestricted movement. The new piCOBOT® Electric package will contain plug & play software to fit UR e-series cobots, but many other useful adaptations will be introduced in the coming year

.png)