Real-Time, High-Resolution Stereo Vision for Industrial Robotics

Software alone isn't always enough to tackle the demands of real-time stereo vision. That's where smart hardware solutions come into play. Think of it as having a specialist to take care of the heavy lifting so you can focus on the big picture.

The Ultimate Guide to Depth Perception and 3D Imaging Technologies

Depth perception helps mimic natural spatial awareness by determining how far or close objects are, which makes it invaluable for 3D imaging systems. Get expert insights on how depth perception works, the cues involved, as well as the various types of depth sensing cameras.

What is Interpolation? Understanding Image Perception in Embedded Vision Camera Systems

Interpolation is a mathematical technique used to estimate unknown values that lie between known data points. Interpolation helps transform raw sensor data into stunning, full-color images in embedded vision systems.

Machine Vision meets every taste

Ensuring safety and accuracy of correct packaging is a high priority in the food industry. In addition to the packaging quality, the high variation of different packaging and labeling is also a challenge.

How NVIDIA Jetson AGX Orin™ helps unlock the power of surround-view camera solutions

The blog explains how these cameras enable precise maneuvering, reduce manual intervention, and enhance safety in various embedded vision applications.

6 Ways AI is Improving Robot Perception and Navigation

The diversity of applications for AI robotic perception improvements will extend Industry 5.0 beyond its perceived potential.

See more, automate better: IDS at the SPS 2024

Around 1,200 companies will be represented in a total of 16 exhibition halls at the trade fair for smart and digital automation. IDS will be taking part for the first time, focusing on industrial image processing for robotics, process automation and networked systems.

2D cameras for positioning and inspecting ultra-fine wires in semiconductor production

Wire bonding is a key process in semiconductor production. Extremely fine wires with diameters of 15 to 75 micrometers are used to create tiny electrical connections between a semiconductor chip and other components.

Stereo vision camera provides 3D information from a distance of approx. 20 centimeters

The great strength of Ensenso B lies in the very precise detection of objects at close range. It provides a wide field of view and an impressively high depth of field.

Picking the right chart - (Semi-)Autonomous surface and underwater mapping for rivers and lakes

On the camera side, the Fraunhofer Institute relies on two uEye FA industrial cameras from IDS. The robust and resilient models with PoE are ideal for demanding environments.

Pallet by pallet - Intelligent robotic vision system destacks up to 800 objects per hour

One of the locations where RODE adds value is for DHL eCommerce in Rotterdam. In this machine, two Ensenso 3D cameras from IDS Imaging Development Systems GmbH are implemented to provide the required image data.

The Core of Optimizing Robotic Performance: Sensors in Warehousing

Without any external input to guide its actions or decisions, a robot would behave like a machine, performing tasks without adaptation or autonomy. Serving as the critical link between the robot and its environment, sensors enable the robot to perceive and interpret.

Trained quickly, inspected swiftly - Handling and defect inspection of indexable inserts

The German medium-sized company has developed a fully automated handling and inspection system in which the DENKnet solution for AI-based image evaluation plays a decisive role and sets new standards in terms of performance, zero-defect production and speed.

Using machine vision without prior programming skills

The integration of professional machine vision applications is usually very complex. Since no programming skills are required for such machine vision software, industrial image processing can thus also provide a valuable contribution to digitization.

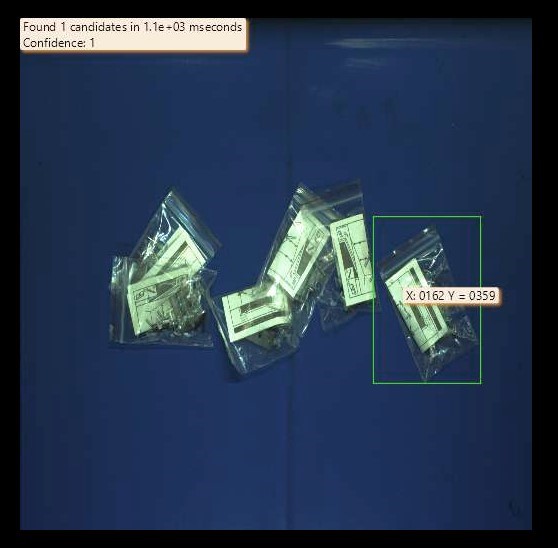

60 Plastic bags per minute perfectly positioned

For fully automated pick-and-place applications, it is important that robots can reliably grip differently shaped and translucent objects, as well as objects with complex surfaces.

Records 1 to 15 of 158

Featured Product

IP Seals for Robots

Freudenberg Sealing Technologies' IPRS (Ingress Protection Seals for Robots) provides reliable protection for robotic systems operating in harsh environments. Designed to prevent dust, moisture, chemicals, and wear from compromising performance, IPRS extends service life and reduces maintenance. The adaptive Z-shaped geometry ensures sealing integrity under continuous motion, making it ideal for high-speed automation and outdoor applications. Manufactured with high-performance elastomers such as Fluoroprene XP and EPDM, IPRS offers exceptional resistance to lubricants, cleaning agents, and extreme temperatures. This makes it the perfect solution for six-axis robots, SCARA robots, AMRs, AGVs, and cobots.

With its low-friction design and durable materials, IPRS enhances energy efficiency and operational reliability in industrial and autonomous robotics. Learn more about our IPRS Seals