Aerobotix Develops All-In-One System for Defense Manufacturer with ATI End-Effectors

Producing the world's most advanced air defense missile requires technological innovation, especially when annual production is set to increase to 500 by 2024.

The dm Drugstore Distribution Center Relies on Piab Suction Cups

An average of 3,500 pallets are delivered and picked there every day. A large part of the pallets is depalletized with Piab's DURAFLEX® suction cups BX52P and fed into the order picking chain.

4 Critical Considerations When Selecting a Robotic End-Effector System

Finding and implementing the perfect end-effector system is reliant on the user giving due consideration to four critical areas. Only when complete understanding of the needs in these four realms is acquired can an educated end-effector choice be made.

Robotics Designed for Harsh Environments

In the following article we will discuss how one company employs creative design techniques and online configuration tools to provide customized motors and gearheads for their latest robotic arm and gripper - able to fit into a wide variety of applications.

Getting the Right Grip: Designing Soft and Sensitive Robotic Fingers

Scientists make a big leap in development of soft robotic grippers by integrating sensing mechanisms into 3D printable fingers.

Advantages of Vacuum driven Soft Grips for Food Production

The main advantage of having lightweight EOAT is the ability to handle the objects while not adding much weight to the end of the robot arm. This enables using smaller robots/machines as all their power can be utilized to handle the food products.

Questions to Ask Before Selecting Your Air Gripper

The array of gripper choices in the automotive, pharmaceutical and electronics and industries for pick-and-place automation systems are numerous. The many gripper styles - all of which have their own size, method of operation, and level of human interaction - is daunting.

Ergonomic Under Load: Vacuum Handling Systems for the Logistics Industry

In order to become more efficient and work more quickly but at the same time protect the health of their employees, it is worth investing in ergonomic lifting devices.

With Piab's Bag Grippers, Sapho Increases Its Pace

The impetus was that we wanted to get more power out of the machine and wanted to pack the pallets cleaner and more dimensionally stable. The technology, the know-how and the service convinced us of Piab, after we looked at several manufacturers.

Smart Gripper for Small Collaborative Robots

With the growth and proliferation of collaborative robots, there has become an increased need for a wide variety of grippers and end effectors in general. One of the more challenging applications is for automated gauging and measurement of small parts.

Robofill 4.0 - Robot and Gripper-assisted Filling Concept for Customized Bottle Supply

The Zimmer Group development team also faced a tremendous challenge in developing special gripper fingers, which were intended to handle any potential type of bottle from 0.33 l up to 0.75 l by gripping the neck and body of the bottle.

The Power of Adaptive Robotic EOAT

The challenge is that traditional robots have been designed to perform a single task extremely efficiently. But when the item or the task changes these traditional machines need to be reintegrated and reprogrammed.

Vacuum Technology for the Digital Factory

In order for electrical vacuum generators, grippers and compact ejectors to be visible to the smart factory, they must provide digital energy and process data in real time.

5 Big Innovations in Robotic End of Arm Tools Landscape

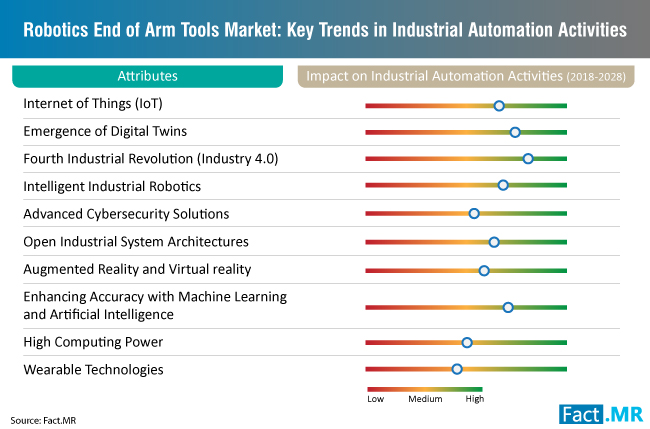

Robotics end of arm tools (EOAT) deployed in various industrial sectors have witnessed drastic transformations vis-à-vis technology advancements and customer demand for greater levels of productivity.

Talking ATX West with OnRobot

Booth #4481 (co-exhibiting with Futura Automation) - Gecko Gripper, that uses millions of micro-scaled fibrillar stalks that adhere to a surface using powerful van der Waals forces - the same way that geckos climb.

Records 1 to 15 of 21

Featured Product

FAULHABER Drive Systems at the Robotics Summit & Expo in Boston from April 30 to May 1 in Hall C at Booth 534

Faulhaber will be presenting their drive systems for robotics and smart technology. Robots are versatile and can be found in many areas, for example, transporting goods, operating on patients or supporting the agriculture industry. With the help of robots, processes can be automated, the flow of materials optimized and employees relieved. Equipped with FAULHABER drive systems, these robots can take on tasks where the demands on function and applications are high.