HP MULTI JET FUSION Helps Campetella Robotic Center Reduce Lead Time and Cost

As a robotic center with deep expertise in industry automation, Campetella is exceptionally

positioned to use HP 3D Printing to produce robotic components and automatic machines parts.

Harvestance - Developing and Designing Vacuum Grippers for Production Line Robots

Harvestance has received numerous inquiries for the design and manufacture of customized, lightweight, and strong grippers for collaborative robots, aimed at automating production lines.

This 3D printer can watch itself fabricate objects

Computer vision enables contact-free 3D printing, letting engineers print with high-performance materials they couldn't use before.

This 3D Printed Gripper Doesn't Need Electronics To Function

This soft robotic gripper is not only 3D printed in one print, it also doesn't need any electronics to work. The device was developed by a team of roboticists at the University of California San Diego.

ABB Robotics showcases future of retail using recovered marine plastic at London's Selfridges

Iconic London department store to showcase future role of robotics at point of consumption. ABB robot 3D additive printing will allow personalized items be ordered on site by customers and produced

in-situ, ready for purchase.

FORD NOW OPERATES 3D PRINTERS AUTONOMOUSLY, INCREASING EFFICIENCY AND REDUCING COST

Autonomous process enables 3D printer to run continuously with no human interaction needed, increasing throughput and reducing cost of custom-printed products

Self-healing materials for robotics made from 'jelly' and salt

Researchers have developed self-healing, biodegradable, 3D-printed materials that could be used in the development of realistic artificial hands and other soft robotics applications.

Purdue researchers test 3D concrete printing system as part of NSF-funded project

Transitioning to clean wind energy could become more cost-efficient as Purdue University researchers test a new technology created by an international startup to anchor offshore wind turbines.

HP Multi Jet Fusion 3D Printing Technology for End of Arm Tooling

When HP set out to develop this technology, the aim was to push beyond prototyping and enable repeatable, higher volume additive manufacturing. We can do this by combining a powder bed fusion approach with HP's Thermal Inkjet (TIJ) technology.

Metal 3DPrinting over CNC for custom EOAT

This small component was stopping them from realizing the full potential of their manufacturing process as they could only run the system when there was someone there to restart the system if a stoppage occurred due to slippage.

Gantry Systems for High Performance 3D Printing Applications

3D Printing motion systems are built from standard 3D Print optimized gantry platforms and pre-configured for use with Nordson Ultimus V (or customized to extruder). The direct hardware integration has been considered.

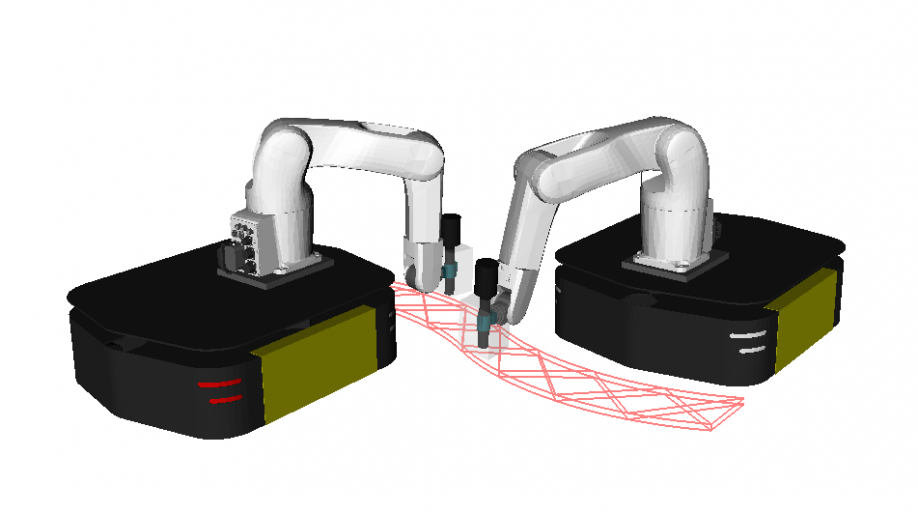

Ridgeback Takes 3D Printing to the Next Level

How can you print something larger than the printer itself? That's the problem researchers Xu Zhang, Mingyang Li, Quang-Cuong Pham, and others set out to solve at the Singapore Centre for 3D Printing...

Rutgers Researchers Create a 3D-Printed Smart Gel That Walks Underwater, Moves Objects

The watery creation could lead to soft robots that mimic sea animals like the octopus, which can walk underwater and bump into things without damaging them.

VTT has 3D printed a smart metal part: a step towards artificial intelligence

VTT's proof of concept demo showed that a range of sensors or smart identifications can be added to 3D printed metal parts during manufacture, in order to track the performance and condition of machines or devices, or verify the authenticity of the parts.

ETH zurich builds DFAB HOUSE using robots and 3D printers

DesignBoom.com: Built using a two-meter high construction robot, the machine works by moving autonomously on caterpillar tracks.

Records 1 to 15 of 113

Featured Product

TM Robotics - Shibaura Machine THE SCARA range

The THE range from Shibaura Machine is an extensive line up of SCARA robots. Available in four arm lengths THE400 (400mm), THE600 (600mm) and the most recent THE800 (800mm) and THE1000 (1000mm), this range is suitable for assembly, handling, inspection and pick and place processes in varied industrial applications. The THE1000 boasts a 20kg payload capacity and an impressive 0.44 second cycle time, providing high speeds for processes with large components. In fact, the range has been recognised for as the price-to-performance leader compared to other SCARA models in its price range due to its impressive speed versus payload capacity.

.jpg)