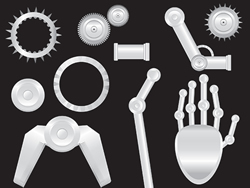

CMU's interactive tool helps novices and experts make custom robots

MIT Builds Invisible Fish Grabbing Robot

Raspberry Pi And MATLAB based 3D Scanner

Global Expert Platform for Production Services in Additive Manufacturing

Is Velo3D Plotting a 3-D Printed Robot Revolution?

3DR Holdings, LLC and Rising Media, Inc. to Host Singapore's Premier 3D Printing and Robotics Event; January 26-27, 2016 at Suntec Singapore Convention & Exhibition Centre

Molding Conference 2016 Announces Complete Technical Program

CES 16 - NinjaTek Announces Two New 3D Printing Materials Designed for Industrial Applications

CES 16 - MarkForged Leads Explosive Growth in 3D Printing Technologies for Manufacturing

3D Printing of Motors and Electronics

Robotic Additive Manufacturing Platform for 3D Printing Composite Parts

3D Printing and Acoustics: Rapid Prototyping of Sound Diffusers

Special Tradeshow Coverage for FABTECH 2015

The 3D Printshow - Learn About 3D Printing

Soft Robotics Project Exo-Biote 3D Prints Living Movement

Records 16 to 30 of 113

First | Previous | Next | Last

Featured Product