Integrated Wheel Drives for Electric Utility Vehicles

Well look at electrically-powered vehicles in this load class of about 100 lb (45 kg) up to 2,000 lb (900 kg), and in particular the types of propulsion systems used in them, including fully integrated traction drive systems.

Gigabit Ethernet Interfaces and Robotics: John Phillips, Pleora Technologies

Were seeing growing demand for interfaces that dont require a traditional frame grabber inside the personal computer (PC), as well as a migration towards smaller form factor PCs with embedded processing.

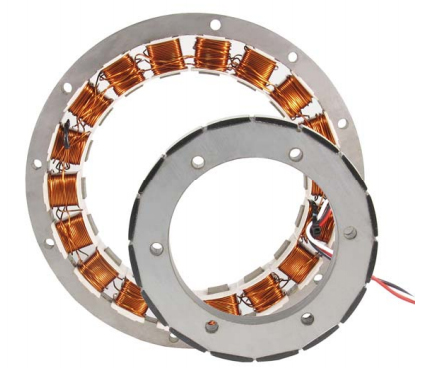

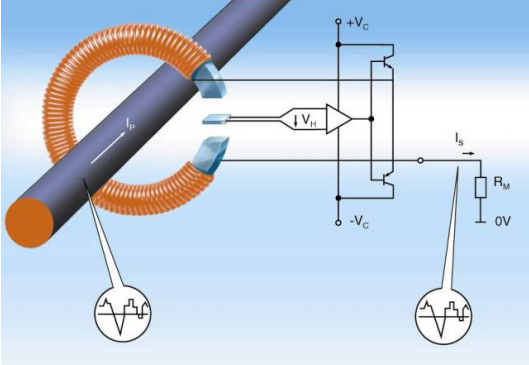

Closed Loop Current Transducer Characteristics

A properly selected current transducer for an application can easily give 25+ years of service. By acknowledging the details behind the data sheet, better performing applications and more robust designs are possible.

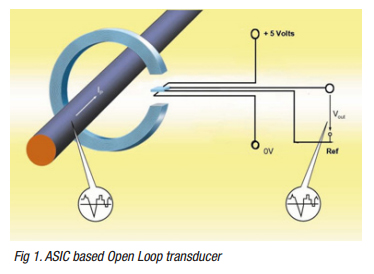

ASIC Based Current Transducers

The implementation of ASIC based current transducers opens up functionality that the traditional discrete component transducers could never achieve.

Flexible Seals for Robotics Systems

The Roxtec system is based on a rubber-sealing module that consists of two halves, a center core, and removable black and blue layers. This construction ensures adaptability to different sizes of cables and pipes.

Face of the Future

Micro drives gives humanoid service robots human traits.

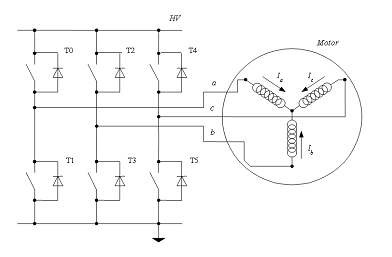

Precise Brushless Torque Control With Only 1 Shunt Resistor

The circuitry to sense precisely the current of three windings of a motor adds a significant space and cost to an electronic board. For that reason, new control algorithms are being developed to work with only one shunt.

Application Case Study: Continental AG, Czech Republic Division

Smart Cameras Provide Additional Benefits to Auto ID Applications

Records 16 to 23 of 23

Featured Product

Discover how human-robot collaboration can take flexibility to new heights!

Humans and robots can now share tasks - and this new partnership is on the verge of revolutionizing the production line. Today's drivers like data-driven services, decreasing product lifetimes and the need for product differentiation are putting flexibility paramount, and no technology is better suited to meet these needs than the Omron TM Series Collaborative Robot. With force feedback, collision detection technology and an intuitive, hand-guided teaching mechanism, the TM Series cobot is designed to work in immediate proximity to a human worker and is easier than ever to train on new tasks.

.jpg)