Smart, Compact Electromechanical Actuators Improve Productivity and Space Efficiency for Industrial AGVs

Cincoze DI-1000 Drives AGVs in Factories and Warehouses

AGV Selection Process for 2022 Must Start with Delivery Commitment Guarantee

The Mini Series Takes a Taxi

As the use of robotics and automation increases, so too does the need to protect these valuable assets.

AGV Robotization: The Solution

Effective Wireless Charging for AGVs

Honeywell Study: Advancements In Warehouse Automation Will Present New Job Classes, Career Opportunities

Integrated Wheel Drives Lower Cost of Mobile Robot Ownership

AGILOX Autonomous Mobile Robots are substantially saving costs by applying Artificial Swarm Intelligence

Intralogistics: AGV vs. AMR

Mobile Robotics and Market Adaptations after COVID-19

MODEX Q&A - Vecna Robotics

MODEX Q&A - Seegrid

Deployment of an Automation Solution - Process, People, Technology

Records 16 to 30 of 46

First | Previous | Next | Last

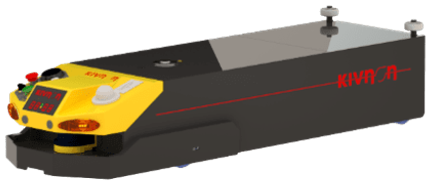

Featured Product

.jpg)