The more functionality AGV designers can pack into a small footprint, the greater will be the value to the end-user. Choosing the right actuation technology is critical to that value, and AGV designers are increasingly choosing smart electromechanical actuators.

Smart, Compact Electromechanical Actuators Improve Productivity and Space Efficiency for Industrial AGVs

Article from | Thomson Industries

Automated guided vehicles (AGVs) can improve industrial productivity by 50 to 70 percent but require adequate room to move about increasingly space-constrained factory floors. The more functionality AGV designers can pack into a small footprint, the greater will be the value to the end-user. Choosing the right actuation technology is critical to that value, and AGV designers are increasingly choosing smart electromechanical actuators when seeking high-performance motion control in a small footprint.

AGVs on the factory floor

In manufacturing applications, AGVs (Figure1) replace much of the human lifting and carrying involved in functions such as delivering blanks to the production line and in transferring goods throughout the workshop, warehouse and assembly line. Most AGVs today are guided by laser or magnetic strips, some use cables and fixed tracks, and more and more are communicating wirelessly.

Fig.1. AGVs increase efficiency in manufacturing applications.

In a typical manufacturing application, a machine operator would signal the need for parts on a logistics management computer system via call terminal at their workstation. On receipt of the request, the management system forwards the request to the AGV management software, which dispatches the nearest vehicle to the task based on priority and optimal pickup and delivery motion. After the operator completes the job, they signal the control system to proceed to the next step in the process.

The host computer always knows the state, position, speed, direction, fault and power of the AGV, and moves it forward, backward, left and right. When encountering an obstacle, the AGV automatically decelerates and stops to avoid a collision. When the obstacle is removed, the AGV operation automatically resumes.

The need for intelligence

As AGV use increases, so does interest in integrating movement with advanced software applications, including enterprise resource planning systems, automatic storage systems, modular conveyor systems and asset management software. Such software guides the creation of optimal workflows for moving materials or functionality from one part of a facility to another with minimal human involvement and effort.

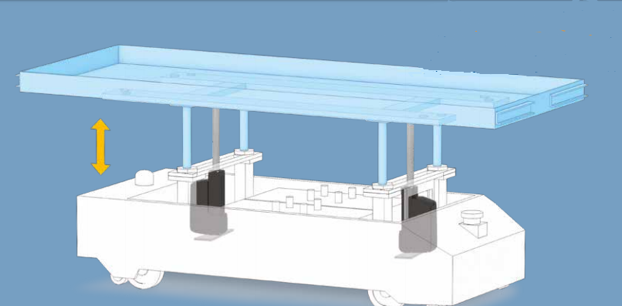

Connectivity is managed by onboard microprocessors and software in modern AGVs and to take the fullest advantage of the potential of digital communications, designers are also deploying smart actuators that have built-in intelligence as well. This enables integration with AGV automation schemes and communications among actuators themselves. The ability to synchronise actuators with each other, for example, could enable creation of an AGV lift table. (Figure 2)

Fig. 2. Intelligent actuators open application integration possibilities for AGVs such as this lifting table, which takes advantage of capability to synchronise movement of multiple actuators

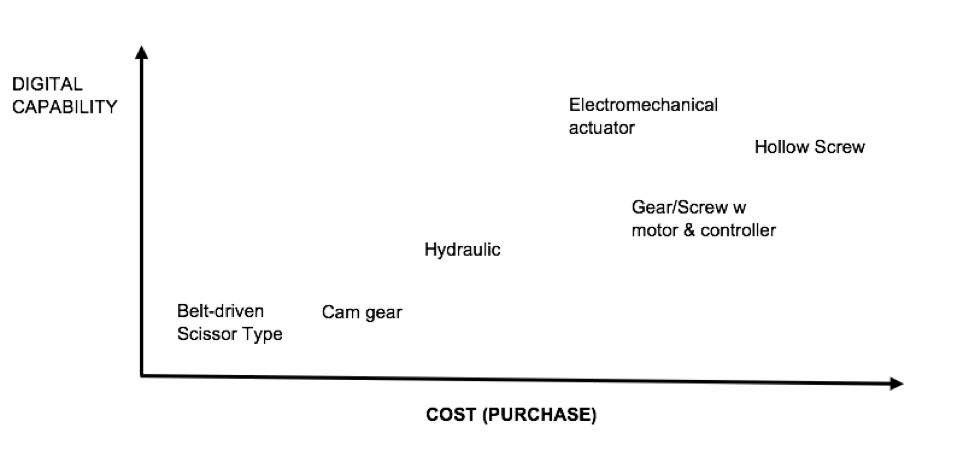

Comparing actuators based on digital integration capability and cost

Electromechanical actuators are best suited for intelligent integration with AGVs intended for plant floor applications. As illustrated in Figure 3, lower-priced, belt-driven, scissor-type cam gear and hydraulic systems have little or no digital integration capability. Gear screws have more digital integration capability, but because they also require an additional motor and controller, it can cost as much if not more than a smart electromechanical actuator. Hollow-screw actuators have comparable digital integration capability and technologies, but their high cost is difficult to justify except for high-speed, high-volume warehousing and distribution applications, such as e-commerce packaging and shipping.

Fig. 3. Comparison of actuation options based on cost and digital capability.

The benefits of compactness

Optimising floor space has bottom-line benefits for all plants, whether you’re comparing the cost of adding buildings or just getting maximum return on existing floor space. Because AGVs can be configured quickly and easily, they are more space-efficient than conveyor belts, which are typically immobile. But AGVs themselves require operating room in the space they need to travel around the plant floor and in their ability to fit in tighter spaces.

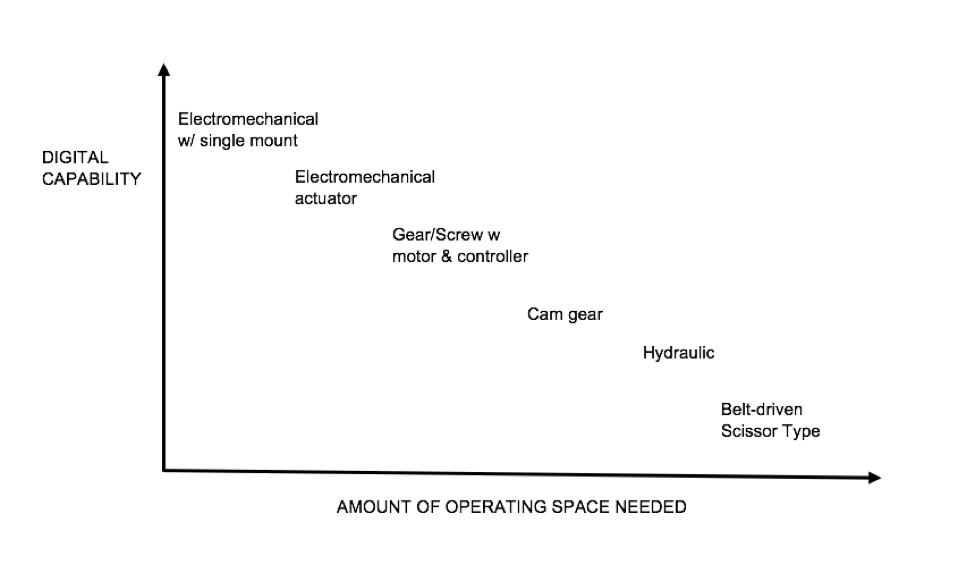

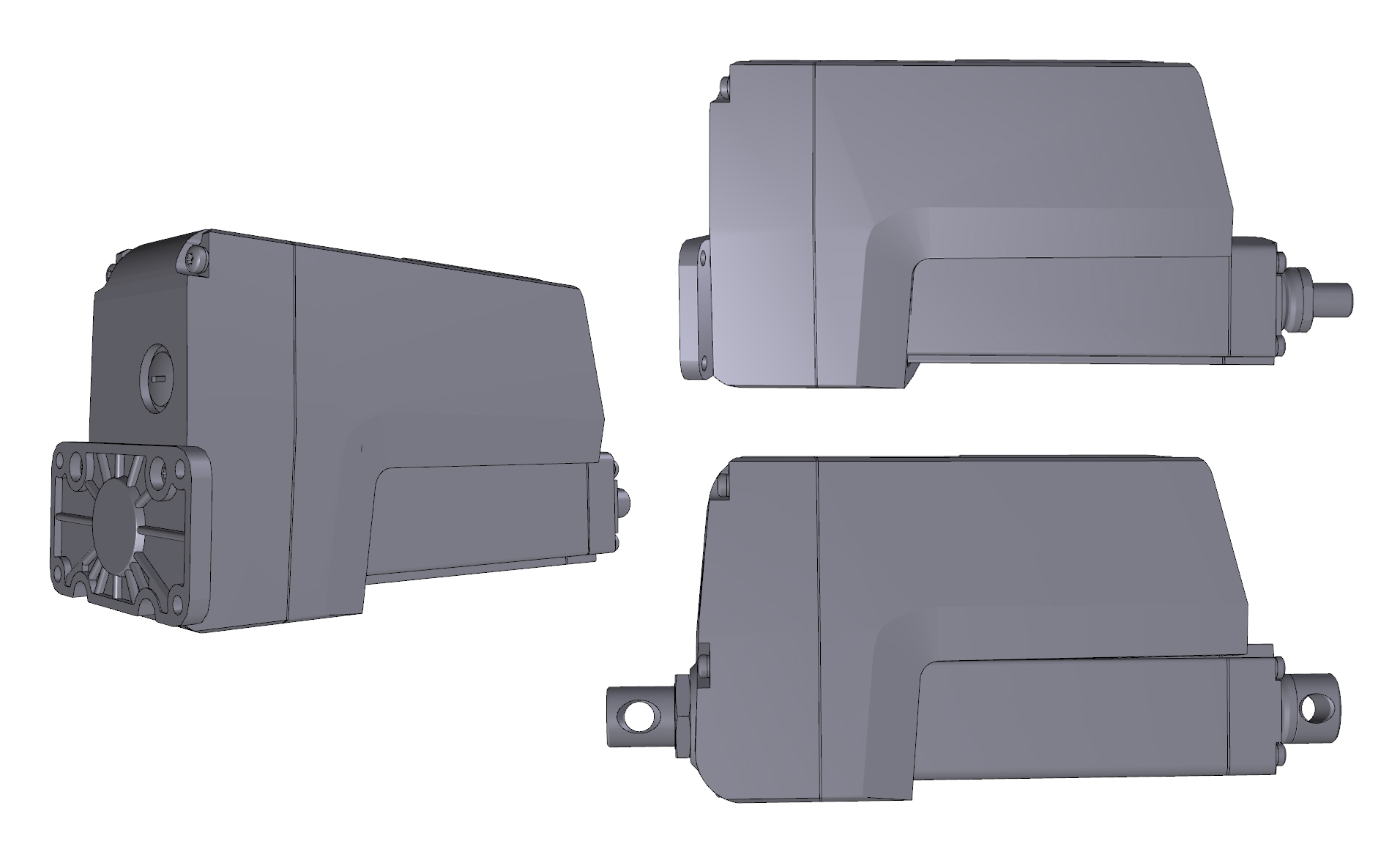

The use of smaller actuators is one way to make operations more space-efficient, but the amount of space required to mount them remains an issue. Typical electromechanical actuators have load adapters in both the front and the rear. Replacing the traditional rear adapter with a mounting flange reduces the overall length and stroke length ratio, returning space to the system designer.

A more compact design makes the AGV easier to deploy in compact spaces, while also reducing energy consumption. The latter is especially important if the AGV design calls for more expensive lithium-ion batteries. Lower energy consumption also means longer work terms and lower charging frequency, which also contribute to overall productivity.

Of the common actuator options, electromechanical actuators require the least operating space to handle a given load, compared to belt, hydraulic or gear-driven options. And among electromechanical options, those with single flange mounting require the least operating space.

Comparison of actuation options based on operating space requirements.

Thomson Industries, for example, offers a rear mounting flange option that reduces the overall length vs. stroke length ratio for its Electrak® HD actuator. The more compact design makes it easier to fit into tight spaces and is ideal when designing different types of automation equipment, AGVs and lifting devices – all while maintaining the digital capabilities mentioned earlier.

With the ability to fit into tight spaces, the Thomson Electrak HD is ideal for AGV space efficiency, with rear mounting flange options reducing the overall length vs. stroke length ratio.

Applications

Wherever goods and parts need to be moved across a level surface, there is a potential role for smart, compact AGVs. Following are examples of industries in which AGVs are commonly used:

- Consumer Goods. AGVs are found in numerous consumer goods industries, including electronics, medicine, chemical, cigarette, textiles and home appliances. They trolley everything from parts for fine work and packaging to heavy palletised objects. In air conditioner manufacturing, for example, this might involve transporting mounting plates, rear nets, covers, panels, motors, air outlets, face frames, covers and capacitors to and from appropriate workstations. In addition to the space efficiencies that electromechanical actuators bring to these applications for large, heavy items such as refrigerators, the onboard intelligence provides the ability to synchronise movement across the load.

- Fiberglass production. In the production of glass fiber, where silica is drawn into thin filaments that are bonded together, AGVs might integrate with CNC machine tools, intelligent industrial robots and production lines. They would automatically transfer the raw silica cake from drawing to drying to cutting and then onto packaging, stacking and storing. The workflow is tightly orchestrated end to end, and the programmability of electromechanical actuators enables fiberglass producers to optimise efficiency.

- Automotive manufacturing. In automotive manufacturing, AGVs replace manual efforts, forklifts and other methods traditionally used to deliver doors, hoods, hinges, bolts and other components to appropriate locations. The high load handling capability of electromechanical actuators is especially valuable in automotive manufacturing.

- Electronics manufacturing. Lack of immediate availability of wafers, fixtures or other components is among the most frequent causes of interruption of electronics production line scheduling, and even slight delays can be costly. By helping ensure that the right components are in the right place and the right time, smart, compact AGVs, aided by programmable actuators, enable high process efficiencies for electronics production.

- Electronics system testing, Electromagnetics of electronic systems such as control panels must be tested in an environment that would not add electrical discharge. AGVs equipped with actuators can be programmed to push sequences of buttons at consistent rates and be moved from test bays to conduct tests without interfering. This requires actuators that have been thoroughly tested for low electromagnetic radiation during electronic actions such as inductive load switching, positive inductance transience, positive and negative coupling, cranking, load dumping, electromagnetic immunity, conducted emissions, and radiated emissions.

Most analysts are predicting sustained growth in AGV usage as global competitiveness continues to heighten. Rising labor costs are a key driver for AGV user growth, but the need to maximise return on all assets is paramount as well. Those assets include the AGVs themselves and the space through which they move. Specifying smart, safe electromechanical actuators that demand minimal space is one significant step that designers can take to optimise today’s AGVs for tomorrow’s applications.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product