Interoperability, the VDA5050 Standard and MiR's approach

The VDA5050 standard is one of the industry's attempts to address this challenge by standardizing communication between multiple different robot types from various suppliers using a common control system.

Averting Factory Fires, Diminishing Downtime: How Thermal Imaging is Safeguarding International Production Lines

The system required a bespoke interface that could accurately test each battery for thermal runaway, and then export and transmit the data to a server to be cross-referenced and analyzed where anomalies were found to be present.

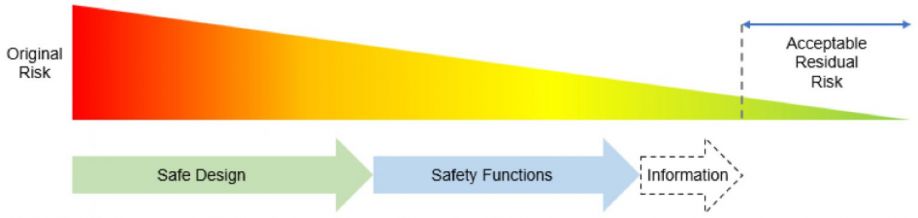

Machine Functional Safety - PL and SIL Ratings

This paper reviews the concept of Functional Safety as it relates to machinery. The design steps for a safe machine are outlined and the methodology for determining appropriate PL/SIL safety ratings discussed.

Forklift Accident Prevention: Understanding Risks and Enhancing Safety

Let's examine the risks associated with forklift operations and look at ways to use safety protocols and smart technology to enhance workplace safety and prevent forklift accidents.

ANSI/A3 R15.08-2 Safety Standard for Industrial Mobile Robot Systems and Applications Now Available

R15.08-2, the American National Standard for Industrial Mobile Robots (IMRs) - Safety Requirements - Part 2: Requirements for IMR system(s) and IMR application(s) provides safety requirements for deploying IMR systems into an industrial environment.

Global Standards for Commercial Robotics

Every business should understand the international standards for commercial robotics and the key organizations and global markets related to them. Companies in every industry worldwide are currently reaping the benefits of automation.

Safely Integrating Robots and AI Into Your Warehouse Workforce

While integrating robots and AI into our warehouses can help with production and quality assurance, care must be taken when this tech is first introduced. Managers need to familiarize their employees with these innovations..

Following the Path to AGV Safety

Although automated guided vehicles (AGVs) are, by definition, designed to run autonomously, they usually need to collaborate with people and therefore move, and react, in a safe, predictable manner.

Opinion: EU AI Act Will Stifle Robotics Innovation

Any policy that slows down the use of automation will cause operational inefficiencies. This is the last thing we need considering the global supply chain crisis.

2021 Top Article - How a Team United in Just 18 Months to Overhaul How America Destroys Its Most Dangerous Chemical Weapons

CRG Automation and its team of engineers - with specialties such as mechanical, electrical and controls -began devising custom engineered solutions, often incorporating

advanced robotics.

As the use of robotics and automation increases, so too does the need to protect these valuable assets.

The risk to humans in warehouses is well known with the UK logistics sector reporting around 28,000 non-fatal accidents at work annually but businesses are now realising the risk of safety to highly sophisticated and expensive assets noting that these too require protection.

AMR Manufacturer, Integrator, and Owner: What Are Your Safety Responsibilities?

The challenge for many companies is how to consistently maintain a safe workplace without creating barriers to productivity or innovation. Enter autonomous mobile robots (AMRs).

Challenges of Developing a Safety System for an Autonomous Work Site

There are many safety standards - most have been developed in the age of the fixed autonomous robot - behind a cage - in a factory, for example. Today, these robots are moving.

Electrostatic Dissipative Flooring vs. Anti-Static Flooring: Which Flooring is Right for Your Facility?

On the surface, anti-static sounds like the right choice. Anti-static means no static, right? Not quite. Read on to learn the key differences between anti-static flooring and electrostatic dissipative (ESD) flooring.

How Robotic Technology Can Mitigate COVID-19

No matter how expertly designed or rigorously tested, every robot is bound to encounter edge cases at some point or another. How the issues are handled and how field ops are done, determines the longevity of the robot system or product.

Records 1 to 15 of 43

Featured Product

OnLogic Helix 511 Fanless Intel 12th Gen Edge Computer

OnLogic's Helix 511 Fanless Edge computer delivers ultra-reliable, fanless computing using Intel® 12th Generation performance hybrid processing. The Helix 511 is a versatile fanless computer capable of powering solutions including advanced automation, light detection and ranging (LiDAR), access control & building automation, or virtually any other IoT or edge gateway functionality needed, with support for 4 simultaneous serial connections. The system is able to reliably operate in temperatures ranging from 0 to 50°C, can accept power input ranging from 12 to 24 Volts, and is Wall, VESA and DIN rail mountable.

.jpg)

.jpg)

.jpg)