Press Brake Robots: Transforming Sheet Metal Bending with Precision and Efficiency

Press brake robots eliminate the challenges of manual sheet metal bending, such as inconsistencies, high labor costs, and workplace hazards. By leveraging robotic arms, sensors, and advanced software, these systems significantly improve accuracy and repeatability.

Developing robotic solutions: partnering for success in micro-motion control

To turn a motion concept into reality, dedicated engineering expertise can be invaluable. Not only can motion engineering support help to improve performance and reliability, but a design partnership can also optimize commercial viability - and reduce time to market.

Integrating Servo Drives with Robotics: Key Considerations for Seamless Automation

In this article, we will explore the key considerations for integrating servo drives with robotics to achieve smoother, more effective automation systems.

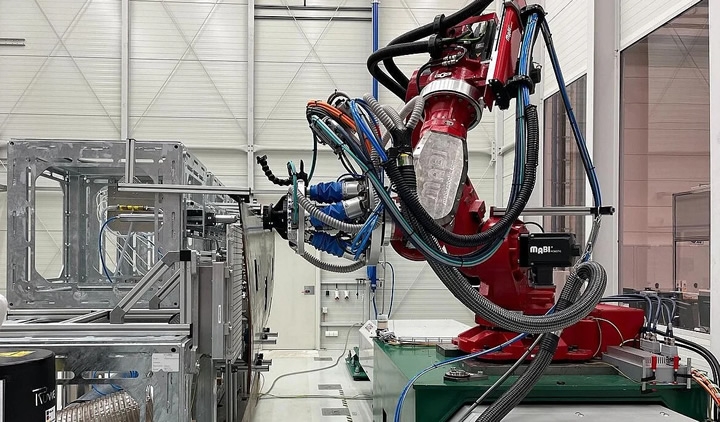

Fast Hexapod Improves Aircraft Manufacturing Process

PI presented a new, high-speed hexapod at the International Aerospace Exhibition ILA Berlin in June 2024, as a partner in the LuFo VI-1: ADMAS (Advanced Machining and Sealing) research project.

What Are the Secrets to Optimizing Motion Control in Robots?

Motion control optimization is about more than ensuring a robot can move. It must also move correctly; meeting the ideal speed, power, direction, length and timing. Assurance in each of these categories is necessary because these are what separate robots from human employees

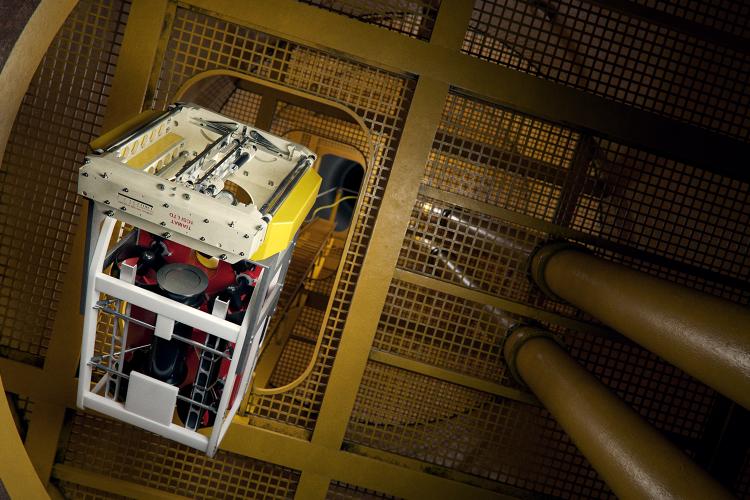

200 Times Faster Subsea Inspection

Precise motion control is helping a new subsea inspection device achieve highly accurate inspection with the fastest-yet speeds of data collection.

SUPPLIER SELECTION FOR CRITICAL MOTION CONTROL APPLICATIONS

In this article, I attempt to arm manufacturers with the questions that they need to ask to ensure that the motion control solution option chosen is right first time and up to the job. These questions should ideally focus on not just capabilities but also values.

Solving Challenges in Machine-Robot Coordination

Using a single machine controller with robot kinematic control built-in means you don't need a separate controller for the robot or series of robots. This integration also puts robot and machine functions into just one development environment.

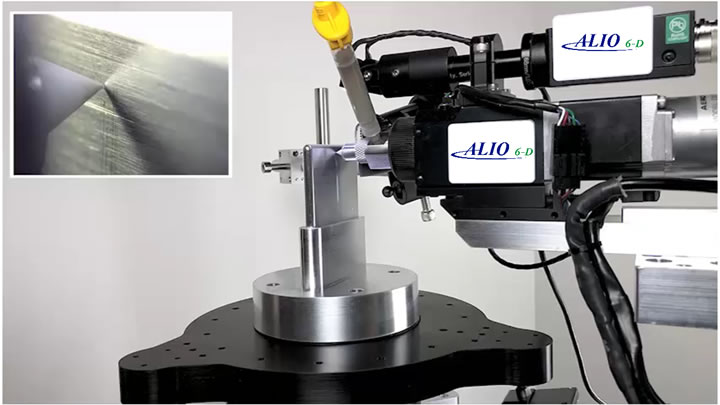

Improving Image Stabilization with Hexapod 6-Axis Motion Simulators for More Reliable Image Capturing

Taking sharp pictures despite fast changing lighting and ambient conditions, recognizing traffic signs or road markings in driver assistance systems, or identifying dangerous situations in surveillance systems - all of this is possible today with the help of modern cameras.

MCRI Webcast Series - Robotics Roundtable

Motion Controls Robotics (MCRI) is hosting a monthly, summer webcast series in 2021. MCRI provides automation solutions for customers by designing and building turn-key end of line applications, fulfillment solutions, and general material handling automation.

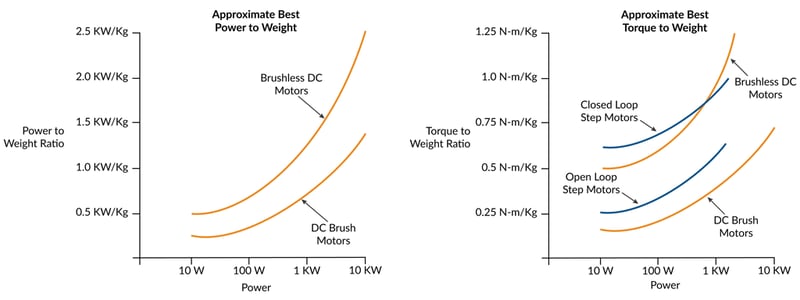

Motion Control Goes Small

Machine designers are increasingly asked to build systems that take up less space, operate on less power, and run with higher performance. Thankfully motion controls are answering the call with new motors, new sensors, and new architectures.

10 Different Options For Controlling Linear Actuators

Below you will find ten different options for controlling linear actuators. This list is intended to give you an overview of what's possible for linear actuator control. It's not exhaustive, there are other options, but these are the ones that will work for most people.

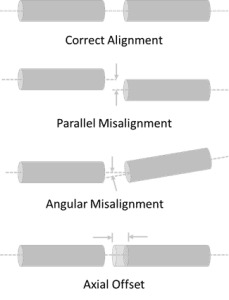

Speed Reducers & Proper Shaft Alignment for Motion Control Applications

While alignment may be within acceptable tolerances during installation, deflection due to loads and thermal expansion or contraction may lead to misalignment. The use of an appropriate flexible coupler can compensate for such minor variations in alignment.

Precision Motion Control Enables Automation

When digital information transforms into precise physical motion, previously infeasible use cases suddenly become possible. This improvement delivered Industry 4.0 to applications such as advanced robotics, Internet of Things (IoT) and Industrial Internet of Things (IIoT),.

Simplifying Motion Control through Integration of All System Components

Integration is about adding value for customers by designing products that include multiple parts of the solution into a single instrument. For motion control hardware, this can mean combining the mechanics along with a motor, encoder, limit sensor, driver, and controller.

Records 1 to 15 of 54

Featured Product

Robotmaster® 2024

Program multi-robot cells and automatically solve robotic errors with ease. Hypertherm Associates announces a new version to its robotic programming software. Robotmaster 2024 addresses key market trends including the support for programming multiple robots in a single work cell and the demand for automatic trajectory optimization and robotic error correction.