Investing in the UK's injection moulding sector - The case for all-electric machines and robotic integration

Traditionally, our manufacturers have relied on hydraulic-powered injection moulding machines in their operations. However, the industry is now at a crossroads, faced with the imperative to embrace technological advancements for sustainability and cost-effectiveness.

Breaking the mould - Shibaura Machine injection moulding machines transform SPAL Automotive's production

Automotive manufacturer SPAL needed to upgrade its production line to meet changing market demands - including faster cycle times and reduced energy consumption.

Reshoring with robots - UK manufacturers can use automation to bring production back home

The advantages of all-electric injection moulding machines demonstrate how automation and robots can help manufacturers bring their operations back home to the UK. Reshoring can be achieved with cost- and energy-efficiency as well as productivity benefits.

ICON Injection Molding Deploys Formic Tend to Boost Production by 20% with Automation Partnership that is "Too Good to be True"

As ICON eyes expansion with a new facility and new, larger corporate customers, they continue to push the boundaries on their technical capabilities and production capacity. They now consider Formic a unique and powerful partner in their growth strategy.

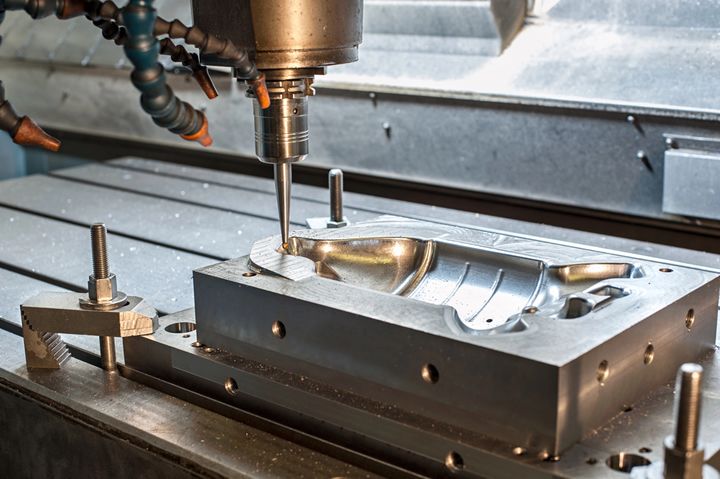

6-axis robots for injection molding open possibilities for manufacturers

6-axis robots in particular, aside from being among the most widely-used industrial machines in general, have become known as the trusted workhorse of injection molding loading and unloading.

Records 1 to 5 of 5

Featured Product

Zimmer Group - THE PREMIUM GRIPPER NOW WITH IO-LINK

IO-Link is the first standardized IO technology worldwide for communication from the control system to the lowest level of automation.