With omnidirectional movement and smart docking with virtually any warehouse cart in under 20 seconds, these new robots are making material handling faster and safer.

Robots speeding up material handling

Robots speeding up material handling

Article from | maxon group

"In 2018, I was with a friend who owned a warehouse that moved a mix of large and heavy goods on both carts and pallet trucks. He showed me the difficulty in moving these carts quickly and accurately, and he asked me for help. I realised that with a special robot design, it could be possible to handle a variety of carts that are already in use, removing the challenges of size, weight, and time,” says Keshav Chintamani, CEO of Tractonomy Robotics, a startup based in Ghent, Belgium. And with a background in robotics research for the space sector, he should know.

Keshav found that many Automated Guided Vehicles (AGV) built for cart handling were based on a design that lifted the payload from below. However, this took time – sometimes over several minutes for the robot to position itself below the cart, and if the cart was slightly misaligned, the AGV was forced to stop and reset. There were often limitations on the weight that these robots could lift including risks of the cart toppling over.

Research turned to AGVs that could tow a cart, however, these AGVs were either permanently attached to the cart, or they offered connection mechanisms with limited accuracy that still took a long time to dock. But, by discovery of a robotic gripper arm as a docking mechanism that could ‘snap on’ securely to the cart, Keshav’s new design would be able to adapt to and safely tow any type of cart.

To give freedom over travel, Keshav planned to combine this docking mechanism with an Autonomous Mobile Robot (AMR) platform. Navigating by lasers to help avoid obstructions and achieve dynamic and accurate motion, the evolution to the AMR would help achieve faster and more efficient warehouse handling.

Omnidirectional movement

The AMR still needed to travel within a space-restricted warehouse to accurately dock with a cart positioned in a densely packed row. Utilising mecanum wheels, this omnidirectional design would allow the AMR to move in crowded spaces with three degrees of freedom. However, the vital step to optimise docking speed and accuracy, as well as onward movement, was specification of a precise four-wheel drive motion system.

“maxon motors are used in many academic research projects because of their performance and reliability, including the space sector research I’d worked on, so they were my first point of investigation,” explains Keshav.

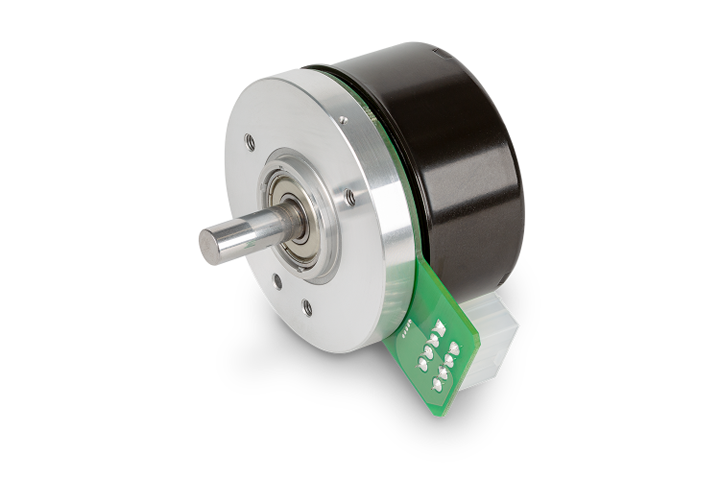

The motion system had to enable high-weight towing, generating sufficient torque to move a payload of several hundred kilograms from a standing start. Operating within cramped warehouse environments, his first AMR design measured just 70cm long and 50cm wide, so a compact motor footprint was vital. Following trials, a flat brushless DC maxon motor, the EC60, was specified for the task. With four motors per robot – one per wheel – the design also had to be cost effective for scaled production, considering the motors also needed integrated high resolution encoders.

High power density

“We trialled these motors in the ATR1 prototype and they were really impressive. They were able to pull a cart with the weight of three people standing onboard - and these were really tiny motors, just 60mm wide,” says Keshav.

With the concept confirmed, Tractonomy Robotics was born, with the inaugural design named the ATR1 – the Autonomous Towing Robot. The ATR1 can pull any type of cart weighing up to 400kg at speeds of more than 1m/s. Aided by a special navigation stack, the robot quickly docks, and the ATR can even detect free spaces and automatically park carts. This navigation system uses cameras and computer vision feedback, and control accuracy is a result of the motors’ speed of response.

“The ATR1 can accurately and reliably dock with carts in under 20 seconds and position itself in tight spaces thanks to sideways manoeuvres, known as ‘strafing’, with subtle adjustments to ensure pinpoint accuracy,” says Keshav.

Demand for heavy load towing

Following trials of ATR1, Tractonomy Robotics received requests to tug heavier payloads such as sheet metal weighing up to 800kg or more. This led to a radical new design, the ATR2, a robot with a unique dual arm adaptive docking system that enables it to handle a range of cart sizes. Tractonomy intends to produce a standard torque and a high torque version of the ATR2, with expected tow capacities of 600kg and 800kg respectively, achieving speeds between 1.8m/s to 2.5 m/s (6.5kmh to 9kmh).

Dimensions of the ATR2 increased to 90x64cm from 70x50cmto allow more batteries and new electronics, but to handle the payload increase yet still fit within a compact footprint, significantly higher torque motors were needed.

“Advice from maxon’s engineers enabled us to use a lower voltage motor to suit the overall system, but still achieve the peak motor speed and peak torque requirements for the higher load, while meeting thermal limitations,” says Keshav. “With this important advice, using just two types of motors, we can offer a single platform suitable for a wide range of carts and payloads.”

When pulling heavy loads at high speeds, stopping power becomes even more important, so the ATR2 includes integrated braking and a 360° safety system that prevents collisions. Operating up to 24 hours a day, component reliability is also key.

“These machines cover 15-20km or more per day under variable conditions. Failures decrease productivity, so it’s very important to have a reliable motion solution,” explains Keshav.

Flexibility in material handling

ATR2 is entering operational validation and Tractonomy is focusing on series production. The AMR is primarily aimed at the manufacturing and distribution logistics sectors which depend on material handling technologies, such as factories, large supermarket warehouses, and postal services. The robots can also be used to load and unload carts from trucks, and can provide a cost-effective replacement of traditional tugger trains, conveyor systems, as well as a safer and automated alternative to forklifts.

Keshav adds: “We’re seeing a growing need for just one type of machine to handle a broad range of material handling applications, because this reduces cost and management complexity for the end user. With just one robot that can apply to multiple material handling functions, Tractonomy is providing this flexibility.”

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Understanding Torque and Speed in Electric Motors

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

The rise of modular robots and the importance of drive train design

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product