Successful AMR implementation requires careful consideration of several key factors: space analysis, floor conditions, and environmental factors, among others.

Preparing Your Facility for Mobile Robots: Key Considerations for Seamless Integration

Article from | Omron Automation

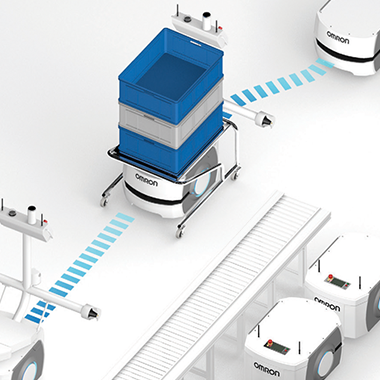

Integrating autonomous mobile robots (AMRs) into your facility can optimize materials transport thanks to the robots’ ability to navigate autonomously, adapt to changing environment, and perform a range of tasks. However, successful AMR implementation requires careful consideration of several key factors: space analysis, floor conditions, and environmental factors, among others.

By evaluating and addressing these considerations, organizations can maximize the benefits of Autonomous Mobile Robots (AMR) and revolutionize facility operations. Let’s take a look at each of these factors and see how they can be properly addressed.

1. Analyzing the facility’s physical space

The first step is to conduct a thorough analysis of the physical space within the facility. Evaluate the layout, pathways, and potential obstacles that could impact AMR navigation. By identifying areas where AMRs can operate effectively, such as wide corridors or open spaces, organizations can optimize movement and minimize disruptions. Careful space analysis ensures seamless integration of AMRs into existing workflows.

2. Examining and correcting for various floor conditions

Assessing the condition and suitability of the floors is crucial for smooth AMR operation. AMRs typically perform best on flat and even surfaces. Any unevenness, loose tiles, or surface imperfections should be identified and addressed to ensure the stability and reliable navigation of AMRs.

By optimizing floor conditions, organizations can facilitate the efficient movement of AMRs throughout the facility.

3. Taking important environmental factors into account

Consider the environmental conditions within the facility that may impact AMR performance. Evaluate factors such as temperature, humidity, lighting, and the presence of dust, debris, or hazardous materials. It is important to select AMRs that can operate effectively in these conditions.

Some AMRs may require additional protection or customization to handle extreme temperatures or challenging environmental factors. By considering the environment, organizations can ensure optimal AMR performance and longevity.

4. Ensuring proper obstacle detection and surroundings awareness

A critical aspect of successful AMR implementation is the robot's ability to detect its surroundings and navigate safely. Evaluate the work area to minimize or eliminate situations where the AMR may encounter challenges in detecting obstacles, such as intersections or blind spots.

Ensure the chosen AMR possesses advanced sensors and perception capabilities to effectively detect and navigate around obstacles. By optimizing the work area and equipping the AMR with robust detection capabilities, organizations can ensure smooth and collision-free operations.

5. Optimizing integration with infrastructure

Evaluate how well AMRs can integrate with existing infrastructure and systems within the facility. Assess compatibility with charging stations, Wi-Fi or network connectivity, and access to power outlets. Integration with management systems, such as inventory or warehouse management, enables efficient data exchange, real-time monitoring, and centralized control. Seamless integration optimizes the overall logistics operations and facilitates the flow of information.

6. Promoting task customization and flexibility

Consider the AMRs' ability to adapt to different tasks and workflows within the facility. Evaluate whether the robots can be easily programmed, reconfigured, or equipped with additional tools or attachments for specific tasks.

Flexibility in task customization enables AMRs to handle a wide range of logistics operations, such as material transport, inventory management, or collaborative tasks alongside human workers. By leveraging the flexibility of AMRs, organizations can achieve enhanced operational efficiency and agility.

7. Ensuring the availability of maintenance and support

Maintenance requirements and reliable support are crucial for the sustainable operation of AMRs. Assess the availability of technical support from the vendor and the ease of performing routine maintenance tasks.

Regular maintenance, repairs, and software updates are essential to keep the AMRs functioning optimally. Accessible maintenance and responsive support ensure minimal downtime and promote continuous operation.

By carefully considering and addressing these key implementation considerations, organizations can successfully integrate Autonomous Mobile Robots into their facility logistics.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Omron Automation

Omron is an industrial automation partner that creates, sells and services fully integrated automation solutions that include robotics, sensing, motion, logic, safety, and more for manufacturers in the automotive, semiconductor, food and beverage packaging and other industries. Established in 1933, Omron helps businesses solve problems with creativity worldwide, with more than 37,000 employees serving over 110 countries. Adept Technologies is now a valued part of the Omron family.

Other Articles

Advancing Machine Design with the Power of Collaboration and AI

Transforming Manufacturing Processes with AMRs: Boosting Efficiency and Adaptability

Maximizing the Value of Collaborative Robots

More about Omron Automation

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product