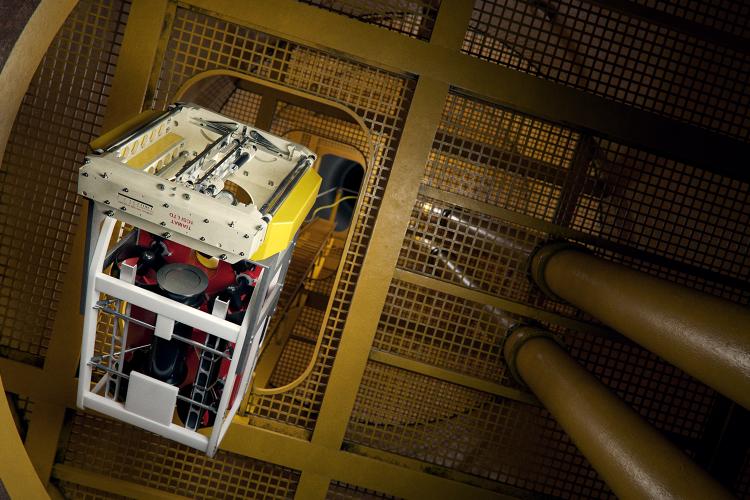

200 Times Faster Subsea Inspection

Precise motion control is helping a new subsea inspection device achieve highly accurate inspection with the fastest-yet speeds of data collection.

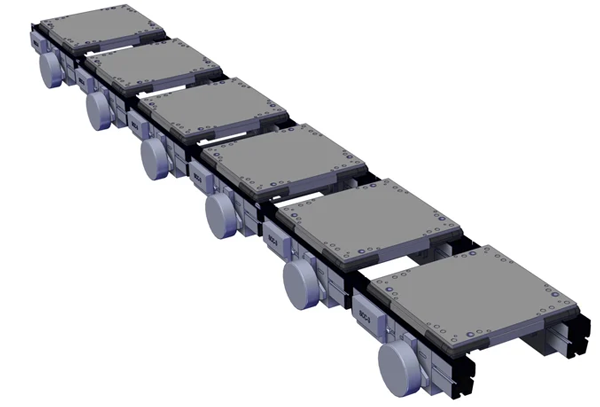

Enhancing Production Efficiency Through Intelligent Transfer Systems

A smooth production process is critical for a company's success. The constantly growing demands of the market and increasing cost pressure require innovative solutions to optimize production. This is where transfer systems come into play.

Case Study: Glide-Line's Zero Contact Zoned Conveyor For Integrator, Mid-South Industrial Automation

Mid-South Automation's team was challenged to find a cost-effective way to make a 34 station modular system, making each module (or section) self-powered.

How Construction Companies Are Automating Workflows

In this article, we look at how construction companies are currently automating workflows and can continue to leverage technology to address workforce challenges.

Comparing XY-Theta Motion / Positioning Stage Options for Precision Automation Applications

These systems can be configured and supplied as individual components or as complete integrated motion systems with custom interfaces, cable management solutions, vacuum feedthroughs and application-optimized integrated granite and aluminum structures.

The Most Common Causes of Spindle Failure

Have you experienced a series of spindle failures, causing you to wonder why? Maybe you're a Quality Control engineer looking for reasons your cuts are going out of tolerance.

HEIDENHAIN In Action at OMIC

Exciting manufacturing research is happening daily at OMIC R&D (Oregon Manufacturing Innovation Center - Research & Development) and many types of HEIDENHAIN precision measurement components are working inside.

Variance and Volume Advantageously Combined One of a Kind in Series

Up until now, users in the metal and plastics processing industries often faced a difficult choice: with CNC lathes and milling machines, one opted either for the largest possible variance or for large volumes, i.e., high quantities.

Why is Robotics-as-a-Service So Important Now

"Robotics-as-a-service" is a model in which customers purchase automation on an "as-needed" basis. This could be monthly pricing or usage-based pricing. Upfront costs are typically negligible or non-existent.

3DMGQ7-GNSS/INS Dynamic Performance Test Report

GNSS and INS performance accuracy is generally tested in an ideal static environment, and often not representative of end use performance. Dynamic environments introduce error sources such as multipath, obscured sky view, vibration, inconsistent RTK data streams and more.

Case Study - Safe Scoring

LHMT GmbH develops highly specialized tools that fully automate not only the actual scoring and milling process of printed-circuit boards, but also the loading and unloading of the sensitive circuit boards.

Avoiding Unnecessary Downtime in Semiconductor Production

Since the CrackScan and EdgeScan inspection solutions have been proven to increase productivity, a semiconductor producer and technology leader has now opted for the ISRA technology that is unique on the market.

The Role of Smart Glasses as a Safe Return to Work Strategy

Pick-by-Vision adds to smart technology because smart glasses learn manufacturers' parts; they memorize the visual appearance including robots and bin locations. Pick-by-Vision predicts and prevents mis-picks and decides the best part to pick next.

What Can 80 Engineers Do with 40 Robots in 24 Hours?

Ian Wright for Engineering.com: The inaugural Robotiq User Conference (RUC) will demonstrate what 80 engineers can do with 40 robots in 24 hours.

Klein Tools - Electrician of the Year Contest

RoboticsTomorrow sat down with Klein Tools to discuss the Electrician of the Year Contest.

The grand prize winner will receive a 2015 Ford F-150 XLT Crew Cab customized by off-road specialists Addictive Desert Designs in Mesa, Arizona.

Records 1 to 15 of 19

Featured Product

IP Seals for Robots

Freudenberg Sealing Technologies' IPRS (Ingress Protection Seals for Robots) provides reliable protection for robotic systems operating in harsh environments. Designed to prevent dust, moisture, chemicals, and wear from compromising performance, IPRS extends service life and reduces maintenance. The adaptive Z-shaped geometry ensures sealing integrity under continuous motion, making it ideal for high-speed automation and outdoor applications. Manufactured with high-performance elastomers such as Fluoroprene XP and EPDM, IPRS offers exceptional resistance to lubricants, cleaning agents, and extreme temperatures. This makes it the perfect solution for six-axis robots, SCARA robots, AMRs, AGVs, and cobots.

With its low-friction design and durable materials, IPRS enhances energy efficiency and operational reliability in industrial and autonomous robotics. Learn more about our IPRS Seals