Reliable Industrial Robots with AI - Enhancing Fail-Safe Operations with Predictive Maintenance

With industrial robots’ hourly operating rate of $2500, the financial impact of their failure can escalate quickly. Thus, it is crucial to effectively avoid such technical disruptions in operations, whether it involves one singular robotic arm or several hundred industrial robots. Malfunctions not only halt production but also significantly inflate inventory holding costs due to the necessity of stocking numerous critical replacement components.

“Getting precise figures on production robot downtimes is challenging, as the estimates vary widely, making it difficult to accurately gauge the actual cost of downtime. However, we know, especially from the automotive industry, that these costs can accumulate to substantial millions annually per facility. The most common failure-prone components include joints, drives, and hydraulics. Over time, robot arms lose precision due to natural wear and tear, robot arms become increasingly less precise over time,” states Viacheslav Gromov, founder of Embedded-AI manufacturer AITAD.

Traditional maintenance models

Robotic producers traditionally rely on rigid maintenance models, while corrective models serve as the standard. However, this approach can even accelerate the wear and tear process, with maintenance typically conducted reactively following failures, based on operational hours, or pre-emptively regardless of the actual condition of the machinery.

“Manufactures are mitigating this issue by implementing Condition Monitoring Systems, which predict future maintenance requirements based on the machine’s current, real state. However, these forecasts often remain imprecise, making condition monitoring merely an advanced variation of failure detection. The real game-changer is predictive maintenance, which offers significant benefits by enabling more strategic maintenance planning,” continues Gromov.

Data Collection: Challenges and Solutions?

Collecting and analysing applicable data for machine utilization is complex. Many robots are typically monitored by limited and less powerful sensors that capture only a fraction of the necessary data. The adage “the more, the better” is particularly true in data collection and data-driven development, where extensive data collection and analysis allow for more accurate predictions about machines’ future conditions. However, the vast data quantities generated, especially from in-depth monitoring, for example, of vibration data, challenge the contemporary network infrastructure.

“Traditionally, edge computing solutions are employed to address this issue. Here, an algorithm or an AI (Artificial Intelligence) filters the most relevant portions of data and only transmits this selection to the control system, where the actual translation occurs. Nevertheless, this process still demands great levels of computing power, which can be costly,” acknowledges Gromov.

Embedded-AI in robots: Higher precision at lower cost

Evaluating the sensor data at their point of origin serves as the most feasible solution to minimize robots’ malfunction rates while simultaneously reducing costs. Recent advancements in the performance capabilities of semiconductors have enabled the integration of an “Embedded-AI” onto chips through highly sophisticated processes. Such Embedded-AI sensors only transmit the relevant evaluation results of their given input, minimizing data transmission volumes. Subsequently, this enables the analysis of even larger datasets, leading to more accurate and precise evaluations.

Utilizing Embedded-AI in robotics reveals their current state of wear and tear, based on which the AI can predict the lifespan of either components or the whole machine (Predictive Maintenance). This Embedded AI surpasses traditional edge computing by identifying unpredictable events, such as anomalies, as well as initiating preemptive countermeasures. For instance, atypical vibration patterns may indicate an impending gearbox malfunction.

“Embedded-AI stands out by offering deeper data insights and cost-effectiveness due to its low resource demands. Essentially, it offers an increase in performance for less money. Performance can be increased economically, enabling proactive, flexible, and cost-efficient maintenance strategies. This shift can replace fixed maintenance schedules with a more effective service approach, creating a win-win scenario for both manufacturers and customers,” Gromov adds.

Customized Development for Specific Use Cases

AI-equipped sensors are developed as bespoke “Embedded-AI system components” tailored to specific customer needs. These components are engineered for specific and concrete use cases before going into mass production. They are designed to integrate seamlessly with the system’s respective bus architecture (LIN, CAN, etc.) and are placed efficiently within the device’s structure. This tailored approach offers a flexibility advantage over standard AI-modular systems, allowing for precise customization of the differing characteristics of robots.

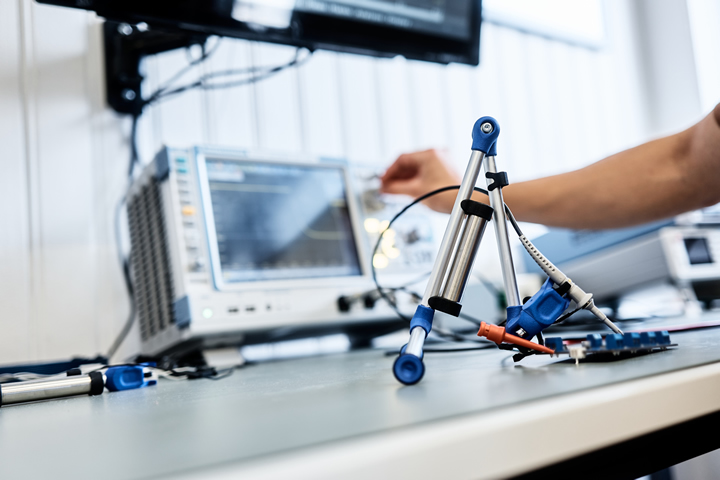

Such sensor components can monitor critical parts of robots – such as drives, joints, gearboxes, bearings, or hydraulic drives – and thus safeguard them via vibration, ultrasound, or laser monitoring. Lasers are particularly suitable when sensors can only be mounted outside of the device. More complex use cases may also require multiple sensors for comprehensive monitoring (Sensor Fusion).

Enhancing robot functionality

Embedded-AI not only improves robot reliability but also offers further application possibilities within robotics. Human-machine collaboration and communication can be enhanced through intuitive controls like voice or gesture commands. Person-recognition solutions can also improve safety while respecting privacy and data protection, as no sensitive data is transmitted. Furthermore, Embedded-AI can refine the functionality of actuators and tools by enabling real-time feedback to ensure operational accuracy.

“As specialists in bespoke Embedded-AI solutions, we are the only global provider of this technology across industries. Our interdisciplinary team is dedicated to developing AI models and electronic components that elevate reliability and safety. Our core competencies are predictive maintenance, user interaction, and functional innovations,” Gromov concludes.

Viacheslav Gromov is the founder and CEO of AITAD. The company develops electronics-related artificial intelligence (embedded AI) that performs locally defined tasks in devices and machines in real time. He is the author of numerous articles and various textbooks in the field of semiconductors. Gromov is active as an expert in various AI and digitalization committees, including DIN and DKE as well as the German government (DIT, BMBF). AITAD is AI Champion Baden-Württemberg 2023, one of the Top100 Innovators 2023 and winner of the embedded award 2023 in the AI category.

AITAD is a German embedded AI provider. The company focuses on the development, testing and series production of AI electronic systems, particularly in connection with machine learning in an industrial context (especially system components).

As a development partner, AITAD handles the entire process from data collection to development and delivery of the system components. As a result, innovative adaptations are made to the product without the need for expertise and only a few resources on the part of the customer. The focus is on future-oriented, disruptive, innovative adaptations with the greatest possible impact on structures and product strategies.

AITAD specializes in preventive/predictive maintenance, user interaction and functional innovations. AITAD takes a different approach to many manufacturers: instead of a ready-made AI solution, an individual system is developed for each customer. In the first step, the company examines how customer products benefit from the use of AI, presents the advantages and possibilities, develops the system at all levels, builds a prototype of the new system in-house thanks to a prototyping EMS line based on collected data and is always on hand for series production and system maintenance. AITAD acts as an interdisciplinary full-stack provider in the fields of data science, mechanical engineering and embedded hardware and software. AITAD also conducts internal and external research into numerous algorithmic and semiconductor fundamentals of AI technology.

In 2023, AITAD received the embedded award in the AI category, the Top100 innovation award for medium-sized companies and was named AI Champion Baden-Württemberg.

For more information visit: https://aitad.de

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product