Dürr builds an energy-efficient paint shop for Stellantis with repurposed robots

Stellantis is expected to double overall capacity at its Kenitra site with a new turnkey paint shop from Dürr. The advanced production technology allows for environmentally friendly and energy-saving high-quality electric car coating. Additionally, paint robots from other plants in the group are being repurposed to conserve resources, too.

The new plant in northwest Morocco is intended to be a model for energy optimization, while simultaneously significantly increasing Stellantis’ production capacity for battery-powered vehicles and hybrid models across the Peugeot, Citroën, and Fiat brands. The newly designed paint shop can handle 30 bodies per hour, a rate identical to the first Kenitra plant, which Dürr built in 2019.

Conserving water, chemicals, and heating energy

Stellantis opted for Dürr’s patented RoDip® rotational dip process for pretreatment and cathodic electrocoating. This innovative method rotates the bodies around their axis, providing exceptional corrosion protection since the dip curves can be individually adapted to different body types, optimizing the immersion, flooding, and draining process. RoDip® consumes much less water, fewer chemicals, and less heating energy than other technical solutions since the conveyor system eliminates the need for inclined tank entrances and exits. This shortens the immersion tank length by up to six meters and reduces tank volume. Lower energy and material consumption also reduces operating and unit costs.

Forty percent fewer carbon emissions

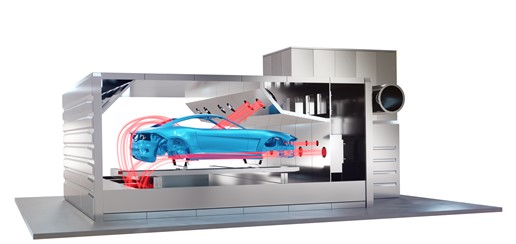

In addition to electrocoating, the Stellantis Group will debut the EcoInCure electric oven featuring innovative air flow conduction that heats and cools car bodies evenly from the inside out. This unique design reduces thermal-structural stress and lowers car body heating time by up to 30 percent. The latest generation of the EcoInCure in the Kenitra plant makes fossil-fuel independence possible by operating with green electricity for an environmentally friendly approach. Compared with its gas-powered counterpart, the electric EcoInCure reduces paint shop emissions by 40 percent, significantly reducing the carbon footprint.

Repurposing for optimum resource use

Stellantis is also enhancing efficiency by adopting wet-on-wet technology, saving both time and energy. The extensive process, which includes two-tone painting across three exterior painting stations, utilizes robots and application technology from existing Italian plants. These robots are equipped with EcoBell2 applicators to integrate seamlessly with existing equipment. In addition, technical equipment, such as air supply units, heaters, and conveyors, are transported from Europe to Morocco for reuse. Repurposing production technology from other plants is a sustainable approach that maximizes resources. In addition, repurposing is a suitable building block for constructing a paint shop within challenging time and cost constraints, all without compromising coating quality and performance.

Pictures

.jpg)

Picture 1: The RoDip® consumes much less water, fewer chemicals, and less heating energy than other technical solutions since the conveyor system does not require inclined tank entrances and exits.

Picture 2: An electric EcoInCure reduces paint shop emissions by 40 percent compared with the gas-powered version, significantly reducing the carbon footprint.

About Dürr

The Dürr Group has been established in the United States since 1970 and currently employs approximately 1,400 people. From the Campus with a state-of-art validation, testing, and training center in Southfield, MI, Dürr USA represents four of the five divisions. Paint and Final Assembly Systems offers equipment for painting and assembly processes, while Application Technology provides paint, sealants and adhesives application systems. Dürr’s Clean Technology Systems division is leading in air pollution control, noise abatement systems, and battery electrode coating lines. Dürr has three locations in the US: Dürr Systems, Inc. in Southfield, MI, and De Pere, WI; Durr Universal, Inc. in Stoughton, WI. The subsidiary Schenck USA Corp., with headquarters in Deer Park, NY, and additional locations in Hudson, MA, and Southfield, MI, offers balancing machines, vibration and condition monitoring systems, spin testing and services for the aerospace, automotive and general industry. The customers of Dürr USA include automotive and commercial vehicle manufacturers, as well as their suppliers, and a diverse group of other industries like the chemical or wood industry. HOMAG Machinery North America operates the production facilities for HOMAG Group in Grand Rapids, MI, which is also the base for the sales and service company Stiles Machinery Inc. The HOMAG Group produces machinery and equipment for the woodworking industry.

The Dürr Group is one of the world's leading mechanical and plant engineering firms with particular expertise in the technology fields of automation, digitalization, and energy efficiency. Its products, systems, and services enable highly efficient and sustainable manufacturing processes – mainly in the automotive industry and for producers of furniture and timber houses, but also in sectors such as the chemical and pharmaceutical industries, medical devices, electrical engineering, and battery production. In 2023, the company generated sales of €4.6 billion. The Dürr Group has around 20,000 employees and 141 business locations in 33 countries, and it operates in the market with five divisions:

- Paint and Final Assembly Systems: paint shops as well as final assembly, testing, and filling technology for the automotive industry

- Application Technology: robots and products for the automated application of paint, sealants, and adhesives

- Clean Technology Systems: air pollution control, coating systems for battery electrodes, and noise abatement systems

- Industrial Automation Systems: automated assembly and test systems for automotive components, medical devices, and consumer goods as well as balancing and diagnostic technology

- Woodworking Machinery and Systems: machinery and equipment for the woodworking industry

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product