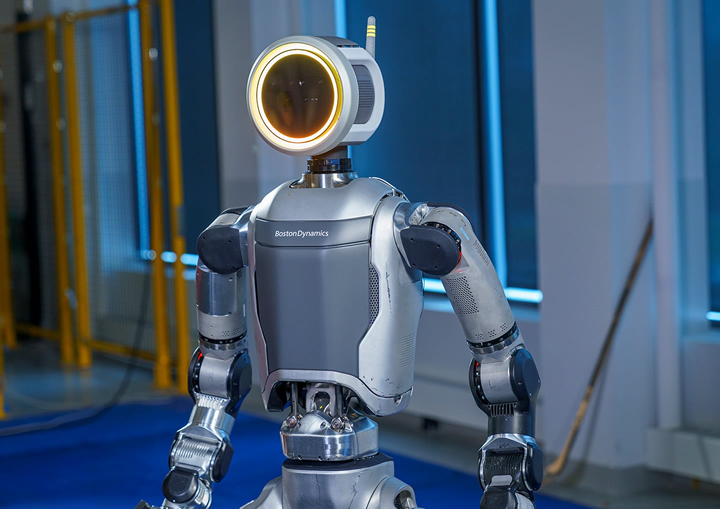

An Electric New Era for Atlas

This week we announced the retirement of our hydraulic Atlas and unveiled what comes next—a fully electric Atlas robot designed for real-world applications. The next generation of the Atlas program builds on decades of research and furthers our commitment to delivering the most capable, useful mobile robots solving the toughest challenges in industry today: with Spot, with Stretch, and now with Atlas.

A decade ago, we were one of the only companies putting real R&D effort into humanoid robots. Now the landscape in the robotics industry is very different. Our customers have seen success with Spot and Stretch and they are eager to tackle the next challenge with Atlas. Given our track record of successful commercialization, we are confident in our plan to not just create an impressive R&D project, but to deliver a valuable solution.

This journey will start with Hyundai—in addition to investing in us, the Hyundai team is building the next generation of automotive manufacturing capabilities, and it will serve as a perfect testing ground for new Atlas applications. In the months and years ahead, we’re excited to show what the world’s most dynamic humanoid robot can really do—in the lab, in the factory, and in our lives.

The Journey with Atlas

Having a meaningful impact outside of the lab requires collaboration beyond our walls. Following the commercial deployment of both Spot and Stretch, we know how to deliver real value for customers. Similar to our Stretch rollout, we will be partnering with a small group of innovative customers, beginning with Hyundai, to test and iterate Atlas applications over the next few years. This is the first look at a real product, but it certainly isn’t the last.

The electric version of Atlas will be stronger, with a broader range of motion than any of our previous generations. For example, our last generation hydraulic Atlas (HD Atlas) could already lift and maneuver a wide variety of heavy, irregular objects; we are continuing to build on those existing capabilities and are exploring several new gripper variations to meet a diverse set of expected manipulation needs in customer environments.

Moreover, a capable robot is only one of the pieces required for a successful commercial solution. Scaled autonomous mobile robot deployments are part of the broader digital transformation ecosystem, requiring IT infrastructure, employee buy-in, connectivity, workflows, safety standards, and operational processes for the robots and the data they generate and rely on. With over 1,500 deployments, Spot is already teaching hundreds of companies how to work alongside autonomous mobile robots. We believe that humanoids will be most effective if they are deployed with in-depth models of a facility and lots and lots of data about how it operates. You can start creating these types of digital twins with Spot today, using Spot, Stretch, and Boston Dynamics to facilitate this operational sea change for your organization.

And we are not just delivering industry-leading hardware. Some of our most exciting progress over the past couple of years has been in software. In addition to our decades of expertise in simulation and model predictive control, we have equipped our robots with new AI and machine learning tools, like reinforcement learning and computer vision to ensure they can operate and adapt efficiently to complex real-world situations.

We also recently launched our Orbit™ software, which provides a centralized platform to manage your entire robot fleet, site maps, and digital transformation data. Today it’s available for Spot, but Stretch and Atlas will also be integrated into this enterprise solution. With a robust team of ML experts shaping our products, we are prepared to bring impactful AI to market immediately—we’ve already started with Spot, and it will get even better and faster with Atlas.

The Role of a Humanoid Robot

This latest iteration of the Atlas robot builds on a long history of innovation and R&D pushing the limits of whole-body mobility and bimanual manipulation. From PETMAN testing protective clothing to the recently retired HD Atlas performing parkour, we have spent over a decade moving the state of the art forward with humanoid robotics.

Traditionally, we have focused on legged robots because we wanted to build robots that could balance and move dynamically—robots that could navigate unstructured, unknown, or antagonistic terrain with ease. The humanoid form factor is a useful design for robots working in a world designed for people.

However, that form factor doesn’t limit our vision of how a bipedal robot can move, what tools it needs to succeed, and how it can help people accomplish more. We designed the electric version of Atlas to be stronger, more dexterous, and more agile. Atlas may resemble a human form factor, but we are equipping the robot to move in the most efficient way possible to complete a task, rather than being constrained by a human range of motion. Atlas will move in ways that exceed human capabilities. Combining decades of practical experience with first principles thinking, we are confident in our ability to deliver a robot uniquely capable of tackling dull, dirty, and dangerous tasks in real applications.

Commercialization takes great engineering, but it also takes patience, imagination, and collaboration. Boston Dynamics has proven that we can deliver the full package with both industry-leading robotics and a complete ecosystem of software, services, and support to make robotics useful in the real world.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product