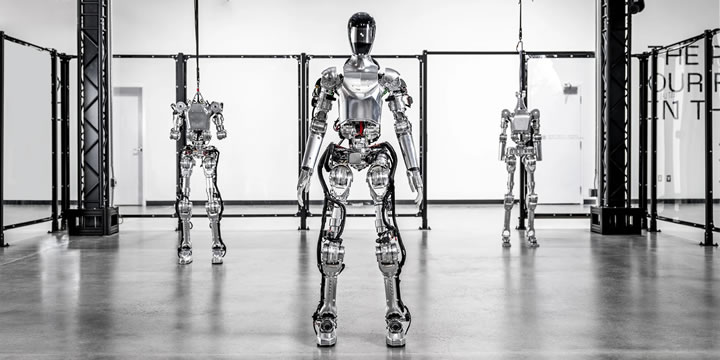

Figure announces commercial agreement with BMW Manufacturing to bring general purpose robots into automotive production

Figure, a California-based company developing autonomous humanoid robots, today announced that it has signed a commercial agreement with BMW Manufacturing Co., LLC to deploy general purpose robots in automotive manufacturing environments.

Figure's humanoid robots enable the automation of difficult, unsafe, or tedious tasks throughout the manufacturing process, which in turn allows employees to focus on skills and processes that cannot be automated, as well as continuous improvement in production efficiency and safety.

"Single-purpose robotics have saturated the commercial market for decades, but the potential of general purpose robotics is completely untapped. Figure's robots will enable companies to increase productivity, reduce costs, and create a safer and more consistent environment," said Brett Adcock, Founder and CEO of Figure. "We look forward to working side-by-side with BMW Manufacturing to integrate AI and robotics into automotive production."

Under the agreement, BMW Manufacturing and Figure will pursue a milestone-based approach. In the first phase, Figure will identify initial use cases to apply the Figure robots in automotive production. Once the first phase has been completed, the Figure robots will begin staged deployment at BMW's manufacturing facility in Spartanburg, South Carolina.

Beyond the deployment of humanoid robots in an automotive manufacturing environment, BMW Manufacturing and Figure jointly will explore advanced technology topics such as artificial intelligence, robot control, manufacturing virtualization, and robot integration.

"The automotive industry, and with it the production of vehicles, is evolving rapidly. BMW Manufacturing is committed to integrating innovative technologies in our production systems to drive our future forward as an industry leader and innovator. The use of general purpose robot solutions has the potential to make productivity more efficient, to support the growing demands of our consumers, and to enable our team to focus on the transformation ahead of us," said Dr. Robert Engelhorn, President and CEO of BMW Manufacturing.

About Figure

Figure is an AI Robotics company developing autonomous general purpose humanoid robots. Our Humanoid is designed for initial deployment into the workforce to address jobs that are undesirable or unsafe, and to support supply chain and manufacturing on a global scale. Figure is based in Sunnyvale, California.

For more information about Figure, visit www.figure.ai.

BMW Manufacturing Co., LLC

BMW Manufacturing Co., LLC is an indirect subsidiary of BMW AG in Munich, Germany, and assembles the BMW X3, X3 M, X5, X5 M and X7 Sports Activity Vehicles; the BMW X4, X4 M, X6 and X6 M Sports Activity Coupes; and the BMW XM. In addition to the South Carolina manufacturing facility, BMW Group subsidiaries in North America include sales, marketing, and financial services operations in the United States, Canada and throughout Latin America; a manufacturing plant in San Luis Potosi, Mexico; and a design firm and technology office in California. For more information on BMW Manufacturing, visit www.bmwusfactory.com.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product