Toyota Research Institute Shares Design to Help Advance the Field of Soft Robotics

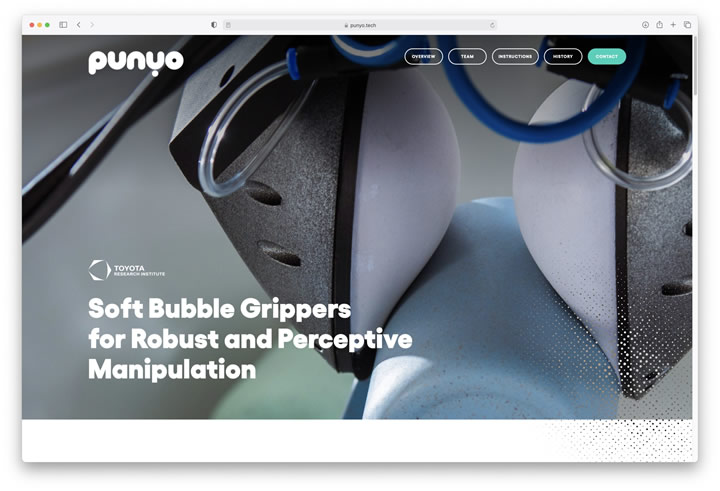

The Toyota Research Institute (TRI) is helping to accelerate the field of soft robotics by sharing the design source files and full build instruction for its innovative domestic robot hands. Today, any research institution or aspiring roboticist can visit punyo.tech and build their own Punyo Soft Bubble Gripper.

"The soft robotics community is small, and the visuotactile sensing community is even smaller," said Alex Alspach, TRI's Robotics Tactile Team Manager and the lead developer of the Punyo Soft Bubble Gripper. "By sharing the blueprints for this gripper with the world, we hope that our friends and colleagues can test our technology, improve upon it, and take us closer to building robotic assistants that help to provide independence, dignity and joy to those with disabilities or age-related challenges."

Building on recently published work, the Punyo project is changing the mechanics of robot manipulation and contact with the world. To this day, most robots are hard to the touch and use rigid grippers, but TRI's air-filled, elastic bubble design allows robots greater flexibility to hold objects better. When combined with cameras on the inside, this shape and force sensing gripper enables robots to respond to and control an object when it slips or moves.

The Punyo bubbles employ state of the art visuotactile sensing techniques that allow a robot to recognize objects by shape, track their orientation in its grasp and sense forces as it interacts with the world. This feedback is critical as robots learn to push and pull on the world safely and robustly while assisting people by opening doors, putting things away, using household tools, and other domestic tasks.

To learn more about Punyo and build your own Soft Bubble Gripper, visit punyo.tech.

About Toyota Research Institute

Toyota Research Institute (TRI), established in 2015, aims to develop active vehicle safety and automated driving technologies, robotics, and other human amplification technology. Led by Dr. Gill Pratt, TRI's researchers use artificial intelligence to benefit society and improve the human condition by creating a future where everyone has the freedom to move, engage, and explore. TRI is based in the United States, with offices in Los Altos, California, Cambridge, Massachusetts, and Ann Arbor, Michigan. For more information about TRI, please visit http://tri.global.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product