Robots are the new normal - Humans should embrace, rather than fear, robot co-workers

According to a recent report from the World Economic Forum, 85 million jobs could be lost and displaced by new technologies in the next five years. It’s no surprise that workers, particularly in manufacturing, worry how these developments will affect their jobs. Here, Nigel Smith, President and CEO of TM Robotics, explains why humans workers shouldn’t fear industrial robots, but rather see them as a bringer of new opportunities.

The robot revolution has been accelerated by the COVID-19 pandemic, with manufacturers opting for automation, rather than crowded factory floors. As technology continues to evolve, and many industries try to keep up with the latest developments, a common fear looms over many workers — will robots take our jobs?

While there’s plenty of evidence that automation does reduce the number of human workers on production lines, the technologies still need humans to operate effectively.

Friends, not foes

The new normal for manufacturers is perhaps best-summarised by Robots in the Workplace: a Threat to — or Opportunity for — Meaningful Work?, a report published in the Philosophy & Technology journal. “Whereas robotization started mainly with industrial robots that substituted humans by performing routine manual tasks,” it reads, “increasingly workers will have to cooperate with robots.”

So, it seems humans and robots could meet each other part-way. Robots, after all need to be programmed and maintained and operating them is also becoming simpler, through the use of programming and human machine interfaces (HMIs). Humans can therefore pass task-orientated functional jobs on to robots, and apply their human intelligence to monitor the robot’s performance and make changes, should something go wrong.

What’s more, according to a study conducted by the Massachusetts Institute of Technology, if manufacturers strike the balance between human and robots correctly, they could reduce their down-time by up to 85 per cent. In other words, collaborations between humans and robots are the way forward.

Enhanced skills

Human-robot collaborations will require two types of change across the workforce, according to Mckinskey & Company.

The first is upskilling, where staff gain new skills to benefit their current roles. The second is reskilling, where workers take on new roles in their organisation. Either path helps companies invest in new innovations, ideas and projects because they can rely on their upskilled and reskilled workers to bring them to life. New skills relating to the installation, daily control, supervision and maintenance of robots will be critical for ensuring success on automated production lines.

Helping hand

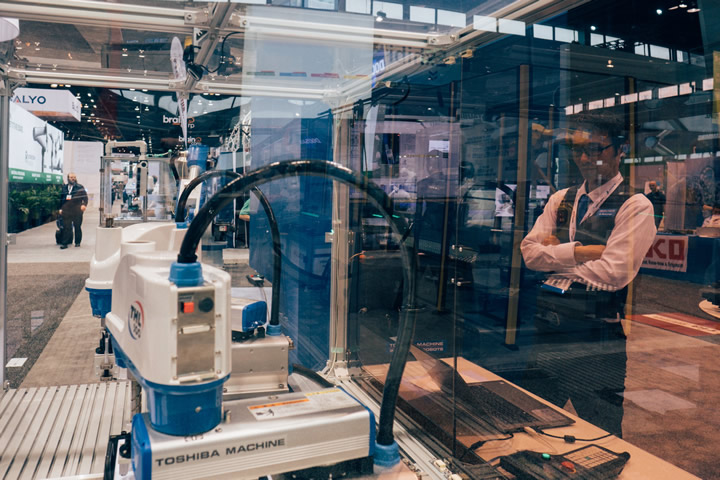

In light of the opportunities for human-robot cooperation, more decision makers are realising that industrial robots could be a friendly face rather than a threat. Indeed, robots can provide much-needed ‘mechanical muscle’ at crucial times. Industrial robots, such as SCARA, 6-axis and Cartesian robots, are better suited to keep up with demands of manufacturing processes.

Robots can otherwise provide much-needed informational support. Take Amazon, for example. Since 2012, the multinational e-commerce company has deployed more than 200,000 warehouse robots around the globe. To ensure its human workers didn’t face job losses, Amazon introduced some changes to their roles. Instead of transporting goods around the factory themselves, human workers now supervise transportation robots to perform these tasks instead.

As Dave Clark, senior vice president of worldwide operations at Amazon, later explained, the company wanted the machines to perform the most monotonous tasks. This leaves people to do jobs that engage them more mentally, creating new opportunities for workers to realise their potential.

Manufacturers should learn from Amazon’s example and look beyond negative views surrounding robotics. Collaborating with robots, rather than being threatened by them, will create opportunities — and that’s nothing to fear.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product