Autonomous Mobile Robots (AMRs) are designed to enhance intralogistics, the complex process of managing and transporting materials within a manufacturing facility, which is critical in automotive production.

Revolutionizing Automotive Manufacturing Intralogistics

Article from | ForwardX Robotics

Revolutionizing Intralogistics: Automotive Manufacturing

Autonomous Mobile Robots (AMRs) are designed to enhance intralogistics, the complex process of managing and transporting materials within a manufacturing facility, which is critical in automotive production. ForwardX Robotics offers a range of AMR solutions tailored to meet the specific demands of automotive manufacturing, from the stamping workshop to the final assembly line. Let’s explore how different AMR models from ForwardX Robotics are improving various intralogistics tasks in this industry.

Stamping Workshop: Efficient Material Transport

The stamping workshop is the starting point for automotive manufacturing, where metal sheets are transformed into components through high-pressure stamping. The process requires precise and timely transport of materials to maintain production flow. ForwardX’s Max O2500-L AMR is a lifting-type robot that can handle heavy loads up to 2.75 tons. It can move omnidirectionally and is designed to transport large material racks from the stamping line to storage or the next processing stage with high precision, ensuring a deviation of no more than ±5mm. This precision allows for robotic arm integration.

This model significantly reduces the need for manual forklifts, minimizing the risk of accidents and ensuring that materials are always where they need to be, on time. The integration of these AMRs helps in maintaining a steady pace in the stamping workshop, crucial for meeting production targets.

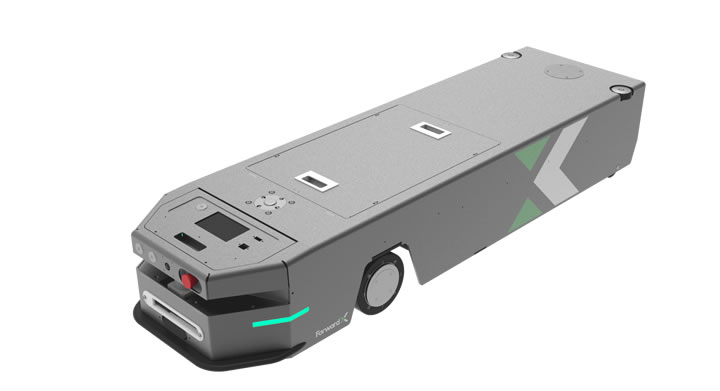

Max O2500-L

Welding Workshop: Streamlined Assembly Line Support

In the welding workshop, where the body-in-white (BIW) structure of the vehicle is formed, the need for accurate and timely delivery of components is critical. ForwardX offers the Flex 600-L and Max 1500-L AMRs, which are ideal for handling medium to large components between welding stations. These robots are particularly effective in transporting parts like wheel covers, side panels, and reinforcement plates, which need to be delivered with high precision to ensure they are ready for welding.

By automating the transport of these components, these AMRs reduce downtime and keep the welding process moving smoothly. Additionally, their ability to operate in mixed production environments, handling multiple models on the same line, adds a layer of flexibility to the manufacturing process.

Flex 600-L

Final Assembly: Precision in Material Handling

The final assembly stage is where all the pieces come together, from interior trims to powertrain components. ForwardX Robotics’ AMRs play a pivotal role in this stage, particularly with the Lynx U1000 and lifting-type AMRs. These robots are used for transporting large components like bumpers, doors, and battery packs directly to the assembly line, ensuring just-in-time delivery and reducing the need for large storage areas on the production floor.

For smaller, high-value components, ForwardX AMRs can also manage SPS (Small Parts Storage) transport. These robots tow multiple carts, each prepped with components for a specific vehicle, directly to the assembly line. This level of automation not only speeds up the assembly process but also improves accuracy, ensuring that each vehicle gets the correct parts.

Lynx U1000

ForwardX Robotics' Competitive Advantages

ForwardX Robotics distinguishes itself in the market with several key advantages:

- Scalability: ForwardX AMRs are designed to scale with your operations, whether you’re running a single production line or a multi-line facility. Offering robots-as-a-service (RaaS) and rapid deployment, ForwardX AMRs allow for easy integration and expansion as your needs grow.

- Flexibility: With models that handle a wide range of load capacities and dimensions, ForwardX AMRs can adapt to different tasks across the manufacturing process, from small parts transport to large assembly components.

- Precision: The precision docking capabilities of these AMRs ensure that materials are delivered exactly where they are needed, reducing errors and rework, which is critical in maintaining the high-quality standards of automotive manufacturing.

- Safety: By automating material transport with the most advanced vision technology in the industry, ForwardX AMRs help reduce the risk of accidents on the factory floor, creating a safer work environment for employees.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product