Learn how to easily and cost-effectively design and procure turnkey automation systems using a robotics platform, taking inspection tasks to the next level.

Low-Cost Robotics Elevate Industrial Inspection Processes

Jan Hennecke, Product Manager, Low-cost Automation | igus

Inspection robots are transforming how industries conduct inspections and maintain quality control, ensuring greater accuracy, efficiency and consistency. Yet while the benefits are clear, the path to automating these processes is not always so.

Some of the challenges include the inherent complexity and cost associated with implementing automated inspection systems, requiring the integration of robots, high-resolution cameras, sensors and software into existing manufacturing processes. The financial investment for these technologies can also be significant, posing a barrier for small and medium-sized companies.

Fortunately, there’s now an easier way. Low-cost robotics, available through an online platform, are enabling manufacturers of all sizes to easily automate their quality control and inspection operations. These systems break down automation solutions into individual components and then find the lowest-cost parts that meet the required specifications. By aggregating the key components in this way, this robotics platform enables manufacturers to design, build and purchase an inspection robot that meets their unique application needs.

Here’s how this robotic platform provides a cost-effective, flexible and user-friendly automation onramp for inspection tasks, helping manufacturers in various industries achieve greater productivity.

Exploring the igus® RBTX Platform

Lowering the barriers to automation, online platforms like igus® RBTX make robotic systems more accessible to companies by addressing two large sources of cost that often keep manufacturers from adopting automation: hardware and implementation.

Addressing the hardware aspect, RBTX breaks down and aggregates individual, low-cost components from leading manufacturers. Sourcing the many elements required in an automated inspection solution is therefore no longer a hassle.

In addition, complex implementation often dissuades manufacturers from adopting inspection technologies. Simplifying this process, RBTX consolidates all necessary information into a single place, saving users time otherwise spent on research. This platform also offers consultation and testing services, guaranteeing the feasibility of the inspection system before it is delivered. Services like remote integration support, video consultations and application tests are also available, ensuring solutions are effective prior to delivery.

A Scalable Roadmap For Automation

By simplifying the process of configuring and implementing automation solutions, RBTX makes it easier for businesses to adopt robotics in their operations. For inspection tasks, solutions can take many forms that vary in cost and complexity. Once a robotic system has been tested and implemented, it’s easy for users to install more of the same system without repeating the integration process. This strategy allows manufacturers to start small and expand their production while reducing upfront costs.

RBTX offers robotic systems starting at just $2,500, with 95% of RBTX solutions costing under $15,000. This affordability, combined with the platform's guarantee of 100% compatibility among components, makes it an attractive option for businesses looking to enhance their quality assurance processes.

For example, ideal for many small and medium-sized businesses is the six-axis ReBeL® robotic arm arm, starting at just under $4,500.00. With six degrees of freedom for greater application flexibility, this solution is compatible with various end effectors, camera systems and accessories and is suitable as a collaborative robot, or cobot. It is up to two times lighter than other cobots and integrates the control system in its base, eliminating the need for a cabinet.

Higher up the ladder in terms of cost and complexity is an entire robotic work cell. For example, a six-axis robotic arm and cell would cost just over $24,000.00. In one application, this system successfully replaced a human worker, who was reassigned to more complex and value-added tasks. The cobot took over the repetitive and monotonous functional inspection of water faucets with high precision and reliability.

This RBTX system, consisting of a six-axis arm and work cell, inspects faucets for proper functionality.

RBTX Robotic Systems for Inspection Applications

Here’s a rundown of what’s possible when using RBTX to design an automated inspection system:

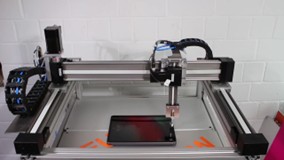

Touchscreen quality assurance. With the proliferation of smart phones and other electronic devices, ensuring the quality of touchscreens has become more critical than ever. The RBTX platform can facilitate this process through the use of linear robots and XYZ gantry systems, controlled via igus® Robot Control software.

Flexible in terms of dimensions and movement patterns, this robotic system can accommodate the varying sizes and interfaces of different touchscreens. The platform boasts a high pick rate of 30 per minute and an accuracy of 0.1 millimeters (mm), ensuring precise, efficient quality checks each time.

This RBTX robotic system inspects touchscreens.

Surface inspection. The RBTX platform supports automated surface inspection applications. In one example, a company that specializes in control technology uses a scanner, igus® line gantry and Apiro® gear to inspect workpiece surfaces for irregularities. The scanner moves with the gantry over each workpiece, performing rotary movements to detect surface defects with 0.5-mm accuracy. This robotic system is also compatible with various end effectors, camera systems and other accessories, making it suitable for inspection tasks across industries.

Quality control of remote controls. In another application, RBTX is used for the quality control of TV remote controls. This application includes an igus® area portal and end effector to test each remote control within a specified time frame, ensuring compliance with production cycle times. This automation of quality assurance processes not only enhances efficiency but also reduces the likelihood of human error.

This RBTX system maintains quality control of TV remotes.

Precision testing. RBTX supports the use of gantry robots for precision testing. These robots are equipped with linear axes that enable multidimensional movements, making them suitable for diverse quality control tasks. For instance, a gantry robot equipped with a two-finger vacuum gripper can position smartphones correctly and test their functions and touchscreens.

Quality assurance with ReBeL® cobot. The ReBeL® cobot, available through the RBTX platform, is another useful tool for automated quality assurance. It is particularly effective in laboratory automation and the quality inspection of facets. This cobot’s versatility allows it to be used in various quality control applications, including the handling of delicate items. It also features a compact design, 360-degree rotatable joints and ability to lift payloads up to 2 kilograms.

Visual inspection with camera systems. The RBTX platform facilitates camera-supported quality assurance systems. These systems use cameras in conjunction with robotic arms to perform detailed inspections of products. For example, the integration of visual servoing technology allows robots to achieve precision levels of 0.01 to 0.02 mm, which is crucial for the quality control of small and intricate components like those found in electronics manufacturing.

Automated circuit board inspection. In the electronics industry, the RBTX platform is used for the automated inspection of printed circuit boards (PCB). This application involves the use of robots to test the quality of PCBs, ensuring they meet the required standards before being integrated into electronic devices. The platform's ability to integrate AI and robotics enhances the precision and reliability of these inspections.

Testing PCBs with an RBTX robotic system.

The Benefits of Low-Cost RBTX Solutions

Adopting RBTX robotic systems for quality assurance and inspection applications offers several benefits, enabling manufacturers to automate processes they have never automated before. These include:

Cost-effectiveness. One of the primary advantages of the RBTX platform is its cost-effectiveness. The platform offers low-cost entry solutions that provide rapid return on investment (ROI). For instance, the deployment of cobots for repetitive inspection tasks has been shown to pay off within a few months, leading to significant cost savings.

Flexibility and customization. The RBTX platform is highly flexible, allowing users to customize automation solutions to meet their specific needs. The platform's built-in configurators enable users to design complete automation solutions without requiring extensive programming knowledge. This flexibility also extends to the selection of robots, end effectors, vision systems and other components, ensuring the final solution is tailored to the user’s requirements.

Ease of use. The RBTX platform is designed to be user-friendly, making it accessible to both novice and experienced users. The platform offers live technical support and an ability to schedule trial operations, providing users with confidence in their selected solutions. Additionally, the platform's in-built intelligence prevents the selection of incompatible parts, streamlining the configuration process.

Get Started With RBTX Today

The RBTX platform is a powerful tool for enhancing quality assurance and inspection processes across various industries. Its affordability, flexibility and ease of use make it an attractive option for businesses looking to adopt or expand automation technologies. By providing a wide range of components and solutions, RBTX enables businesses of all sizes to improve their quality control processes, ensuring that their products meet the highest standards of quality and reliability.

Learn more at rbtx.com.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

igus

The mission of igus® is to use its innovative polymer materials to develop products that provide creative solutions and exceed our customers' expectations while delivering fast, accurate service.

Other Articles

7 Cable Management Mistakes to Avoid

New Exoskeleton is Revolutionizing Work Processes

The Less is More Approach to Robotic Cable Management

More about igus

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product