Technology may not be able to solve all the problems, but it should impact warehouse operations, as did the advent of modern pallets around 1917 and the lift truck, which eventually became the forklift.

The Warehouse of the Future: Where Sci-Fi Meets Supply Chain

The Warehouse of the Future: Where Sci-Fi Meets Supply Chain

Ashish Kumar, Assistant Vice President of Operations | Chetu, Inc.

Traditional warehouses are dangerous workplaces.

Warehouse injuries and illnesses nearly doubled from 42,500 to 80,500 between 2016 and 2021. In 2022, forklift accidents caused 73 deaths and thousands of lost work hours in 2021-2022.

While the increase in the number of warehouses during these five years may inflate the statistics, the raw numbers still paint a hazardous work environment for warehouse employees.

The Rise of Smart Warehouses

Before software technology, traditional warehouses used workers pushing dollies or driving forklifts to store and retrieve crates. Remember the ending of "Raiders of the Lost Ark," when a worker pushes the Ark of the Covenant crate to its final resting place, where it is lost amongst countless crates — lost to history forever.

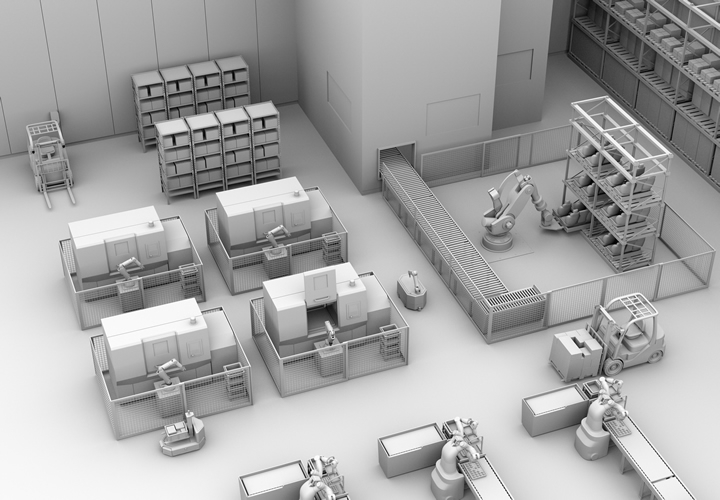

Future “smart” warehouses are more likely to resemble "Star Wars." Robots like R2D2 are doing the heavy lifting, working with humans, while drones fly back and forth, all powered by Artificial Intelligence.

Although tomorrow’s warehouses offer improved safety using innovative AI-driven technology like Machine Learning and Computer Vision, they can’t guarantee absolute safety. Still, robots will take over the more dangerous aspects of working in a warehouse, such as lifting heavy crates and chemical containers. This tech will also increase operational efficiency by tracking where each item is at any given time and using data-driven analytics to determine overstocking or restocking problems.

All of this new technology is desperately needed in the warehouse industry, which is facing an ongoing shortage of workers fueled by the continued dramatic growth of e-commerce. Some estimate that warehouse facilities will increase by 20 percent worldwide by 2025. There is also added pressure for faster turnaround times because of the "Amazon Effect,” which has conditioned consumers to expect orders the next or even the same day.

Technology may not be able to solve all the problems, but it should impact warehouse operations, as did the advent of modern pallets around 1917 and the lift truck, which eventually became the forklift.

Robots and Automation: The New Warehouse Staff

The "smart" warehouse is more than a sci-fi fantasy. This vision of a futuristic warehouse is closer to reality than you might think.

Amazon uses an AI-powered robotic system called “Sparrow” “to handle millions of items,” and Walmart will be “rolling out 19 autonomous forklifts across four high-tech DCs.” Another giant retailer, Alibaba, uses an AI-driven supply chain system that helps it “examine and optimize inventory, forecast demand, and generate replenishment plans.”

Here are some automated systems that companies are utilizing:

- Automated systems such as Autonomous Mobile Robots, Automated Storage and Retrieval Systems, and Conveyor Systems streamline the movement and storage of goods.

- Collaborative Robots (Cobots) work alongside human employees, while Aerial Drones assist in inventory management and surveillance.

- Picking, Palletizing/Depalletizing, Sorting, Labeling, and Packaging Robots automate various tasks in the fulfillment process, and Security Robots enhance safety and security.

Although a small percentage of warehouses use driverless forklifts, that number is expected to grow significantly in the next 10 years. MarketsandMarkets.com estimates that the autonomous forklift sector will almost double from $4.6 billion in 2023 to $8.8 billion by 2028.

Just as AI impacts other industries, some workers may lose their jobs. However, a “smart” warehouse may generate new jobs for the workers, so companies should invest in retaining their workers to take on new roles and responsibilities, and train human team members to work alongside robots.

MTC Recruitment suggests companies need to encourage their employees to adopt a continuously learning attitude and provide upskill training in:

- Data literacy

- Data analytics

- AI and robotics basic

- Robotics maintenance and repair

- Cybersecurity

- Machine Learning and AI programming.

Another question is how human workers will interact with AI robots. Will it be like talking to Data, a fully functional android on Star Trek: The Next Generation? Right now, it doesn’t appear so.

ScienceNews.dk says recent research that compared Germany to the U.S. suggests that “people who work with the robots suffer negative mental health effects – and are more likely to misuse drugs or alcohol.” The article points out that drug use has increased more in the U.S. workforce because robots have caused more job losses than in Germany.

AI: The Key to the “Smart” Warehouse

AI software will power the brains of the warehouse, maximizing inventory management, improving order fulfillment accuracy, and boosting operational efficiencies. Machine Learning, Computer Vision, and IoT sensors will provide real-time monitoring that tracks every step in the warehouse operation. With its ability to learn from data and experiences, Machine Learning or Deep Learning will continue optimizing warehouse operations.

AI algorithms enable inventory optimization by analyzing historical sales data, seasonal trends, and external factors to forecast supply and demand, eliminating stockouts and maintaining items that customers want. By using data collected from sensors on AI-automated machines, warehouse managers will receive analyses that predict maintenance problems before they occur, thus minimizing downtime and costly repairs.

Companies will use AI to maximize delivery routes, saving on truck wear and tear and cutting fuel costs. Delivering packages faster increases customer satisfaction. These robots often integrate with Warehouse Management Systems and Fleet Management Software for seamless coordination and optimization.

An added benefit is that “smart” warehouses should positively impact the environment by reducing waste, optimizing energy usage, and streamlining transportation routes.

Challenges to Implementing a “Smart” Warehouse

While these technologies offer promising benefits, their implementation can be challenging, such as high initial costs, integration complexity, increased cybersecurity needs, underestimating the need for high-quality data, worker skills gaps, scalability, regulatory compliance, maintenance and upkeep demands, and employee resistance to change.

These challenges, however, are not insurmountable. To achieve success, companies must plan the switch to automation. They need cross-functional teams to provide different perspectives, which are imperative to make the change go smoothly. They also might want to implement smart automation in stages to ensure the new workflow is operating efficiently. A pilot program would show executives, managers, and workers the benefits of the new automated system before taking the next step.

Integrating legacy systems into the new AI-powered technology will be a major challenge. To successfully integrate both systems, companies will need highly skilled software developers who understand the technology and the warehouse industry.

What does the future hold for smart warehouses?

Looking ahead, the potential for smart warehouses is vast.

An article, Supply Chain 24/7, suggests that warehouses will move to urban centers but, more importantly, will use 3D printing technology “to ‘print’ products on demand and then package and deliver them just as they do products from inventory.”

The article also states that technology “will play a significant role in delivering the speed and efficiency required and automating the movement of products from large regional warehouses to the urban distribution centers while enabling faster picking, loading, and delivery of these products.”

Advanced technology like drones, which manage inventory, Augmented Reality to assist workers, and blockchain, which creates supply chain transparency, already exist and will find their way into tomorrow’s “smart” warehouse. The future of “smart” warehouses is being built today and will evolve as assuredly as AI technology advances.

As Assistant Vice President of Operations at Chetu, a global software solutions and support services provider, Ashish Kumar oversees multiple portfolios, including SAP, Cybersecurity, Manufacturing, Retail, Energy, IT Service Management, and Supply Chain. He brings expertise in Artificial Intelligence/Machine Learning to these projects. With nearly 15 years of service at Chetu, Ashish is a Certified AWS Solution Architect, Project Management Professional, and Scrum Master.

As Assistant Vice President of Operations at Chetu, a global software solutions and support services provider, Ashish Kumar oversees multiple portfolios, including SAP, Cybersecurity, Manufacturing, Retail, Energy, IT Service Management, and Supply Chain. He brings expertise in Artificial Intelligence/Machine Learning to these projects. With nearly 15 years of service at Chetu, Ashish is a Certified AWS Solution Architect, Project Management Professional, and Scrum Master.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product