The intelligent IDS NXT cameras are now able to detect anomalies independently and thereby optimize quality assurance processes. For this purpose, users train a neural network that is then executed on the programmable cameras.

Update for the AI System IDS-NXT Cameras Can Now Also Detect Anomalies

Update for the AI System IDS-NXT Cameras Can Now Also Detect Anomalies

Article from | IDS Imaging Development Systems GmbH

In quality assurance, it is often necessary to reliably detect deviations from the norm. Industrial cameras have a key role in this, capturing images of products and analyzing them for defects. If the error cases are not known in advance or are too diverse, however, rule-based image processing reaches its limits. By contrast, this challenge can be reliably solved with the AI method Anomaly Detection. The new, free IDS NXT 3.0 software update from IDS Imaging Development Systems makes the method available to all users of the AI vision system with immediate effect.

The intelligent IDS NXT cameras are now able to detect anomalies independently and thereby optimize quality assurance processes. For this purpose, users train a neural network that is then executed on the programmable cameras. To achieve this, IDS offers the AI Vision Studio IDS NXT lighthouse, which is characterized by easy-to-use workflows and seamless integration into the IDS NXT ecosystem. Customers can even use only "GOOD" images for training. This means that relatively little training data is required compared to the other AI methods Object Detection and Classification. This simplifies the development of an AI vision application and is well suited for evaluating the potential of AI-based image processing for projects in the company.

Another highlight of the release is the code reading function in the block-based editor. This enables IDS NXT cameras to locate, identify and read out different types of code and the required parameters. Attention maps in IDS NXT lighthouse also provide more transparency in the training process. They illustrate which areas in the image have an impact on classification results. In this way, users can identify and eliminate training errors before a neural network is deployed in the cameras.

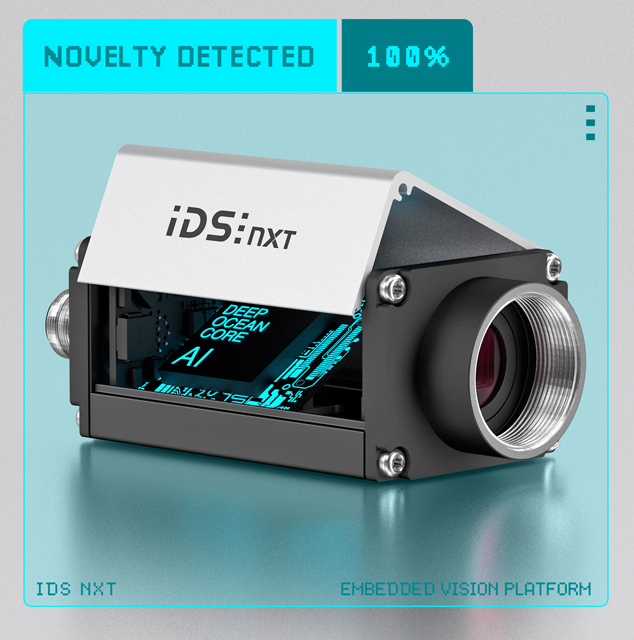

IDS NXT is a comprehensive AI-based vision system consisting of intelligent cameras plus software environment that covers the entire process from the creation to the execution of AI vision applications. The software tools make AI-based vision usable for different target groups – even without prior knowledge of artificial intelligence or application programming. In addition, expert tools enable open-platform programming, making IDS NXT cameras highly customizable and suitable for a wide range of applications.

IDS NXT is a comprehensive system consisting of software and hardware for image evaluation with AI

About IDS Imaging Development Systems GmbH

IDS Imaging Development Systems GmbH is a leading manufacturer of industrial cameras and pioneer in industrial image processing. The owner-managed, climate-neutral company develops modular concepts of powerful and versatile USB, GigE and 3D camera as well as models with Artificial Intelligence (AI). The almost unlimited range of applications covers multiple non-industrial and industrial sectors of equipment, plant and mechanical engineering. The AI image processing platform IDS NXT is extremely versatile and opens up new areas of application where classic rule-based image processing reaches its limits. With visionpier, IDS operates an online marketplace that brings together suppliers of ready-made image processing solutions and interested end customers in a targeted manner.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

IDS Imaging Development Systems Inc.

World-class image processing and industrial cameras "Made in Germany". Machine vision systems from IDS are powerful and easy to use. IDS is a leading provider of area scan cameras with USB and GigE interfaces, 3D industrial cameras and industrial cameras with artificial intelligence. Industrial monitoring cameras with streaming and event recording complete the portfolio. One of IDS's key strengths is customized solutions. An experienced project team of hardware and software developers makes almost anything technically possible to meet individual specifications - from custom design and PCB electronics to specific connector configurations. Whether in an industrial or non-industrial setting: IDS cameras and sensors assist companies worldwide in optimizing processes, ensuring quality, driving research, conserving raw materials, and serving people. They provide reliability, efficiency and flexibility for your application.

Other Articles

2D cameras for positioning and inspecting ultra-fine wires in semiconductor production

Picking the right chart - (Semi-)Autonomous surface and underwater mapping for rivers and lakes

Pallet by pallet - Intelligent robotic vision system destacks up to 800 objects per hour

More about IDS Imaging Development Systems Inc.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product