The use of robots in automotive manufacturing processes enables a very high degree of repeatability and precision, resulting in process optimization and increased productivity. This is how the increasingly high industry standards demanded by manufacturers are met.

Robots in Automotive Industry: How to Use Them to Increase Efficiency

Robots in Automotive Industry: How to Use Them to Increase Efficiency

Article from | Arcos Research & Development

Intelligent automation solutions enable automakers to remain profitable and competitive over time, even in a market environment that is increasingly competitive and difficult to sustain.

Intelligent automation solutions enable automakers to remain profitable and competitive over time, even in a market environment that is increasingly competitive and difficult to sustain.

This realization has become increasingly established among top management, recording strong growth in the international robotics market in recent years. According to the International Federation of Robotics, an all-time high in sales was reached in 2021 with more than half a million robots installed in one year, experiencing a 31 percent growth over previous years.

The use of robots in automotive manufacturing processes enables a very high degree of repeatability and precision, resulting in process optimization and increased productivity. This is how the increasingly high industry standards demanded by manufacturers are met.

Within this specific field, robots are widely used for spot welding and painting, but the application possibilities are varied and cover the entire automotive supply chain. For years, Arcos has worked alongside multiple companies providing robot solutions for the automotive industry intended for surface finishing of automotive parts and components.

What are the needs in this area and why do robots ensure they are fully met? Let us look at it below, with some examples of Arcos applications.

AUTOMOTIVE INDUSTRY: THE NEEDS

HOW ROBOTS ARE EMPLOYED

To give examples: robots are useful for carrying out the loading and unloading of CNC machining centers; for transferring metal molds from one press to another; for avoiding dangerous work for the operator; for cutting and finishing various automobile materials, polishing molds, etc.

In the latter case, the intervention of machines concerns precisely surface finishing. The use of robotics for finishing processes is followed with extreme care and avant-garde by Arcos, which has been present and has been engaged in the field since 1965.

SOME EXAMPLES OF APPLICATION WITH ARCOS

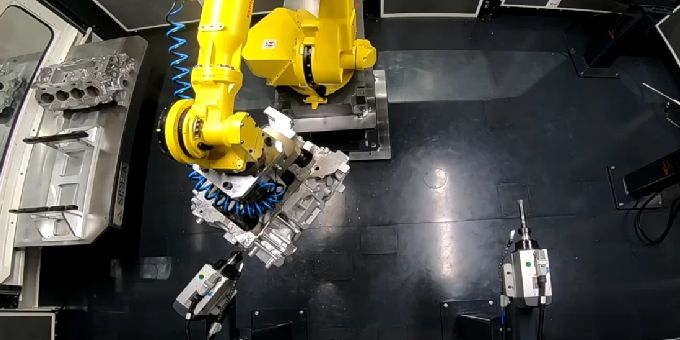

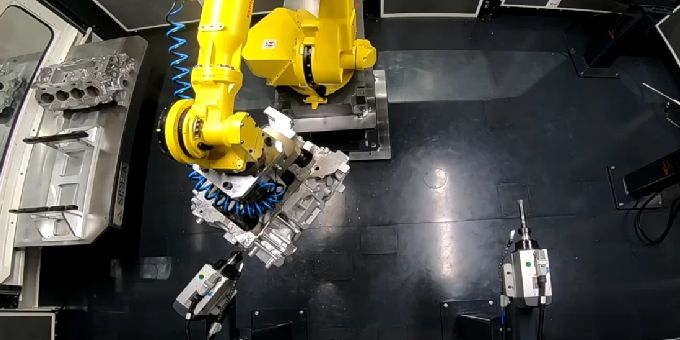

PRECISION DEBURRING OF SUPERCAR ENGINE BLOCK

In cases where there is a need to machine elements with poor accessibility – because of a particular shape characterized by critical working points – specific tools mounted on electrospindles are integrated and used.

POLISHING OF ROOF RAILS

The result is smooth, high-gloss bars that require no manual retouching after processing.

CONCLUSIONS

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (1)

Featured Product