To run at peak efficiency 24/7 and support the sophisticated systems of autonomous robots, automated inventory identification, and other emerging technology, warehouse management and IT teams must consider new networking options.

Robotics of Tomorrow: The Right Network for Warehouse Peak Efficiency

Robotics of Tomorrow: The Right Network for Warehouse Peak Efficiency

Geoff Smith, Executive Vice President of Global Sales and Marketing | Rajant

As the worldwide warehouse growth climbs past 151,000 and e-commerce continues its substantial rise into the third calendar year of the pandemic, operations and warehouse management seek to solve the internal issues that impact coverage, capability, and stability specific to the U.S.’s 10 billion square feet of warehouse space. To run at peak efficiency 24/7 and support the sophisticated systems of autonomous robots, automated inventory identification, and other emerging technology, warehouse management and IT teams must consider new networking options. Doing so creates a fully-functioning warehouse that increases productivity, speed, and accuracy by eliminating issues with connectivity. It also meets the operational potential of all robotic and technological systems within the environment and safely executes dangerous or difficult processes that require continuous connectivity.

The Need to Provide Unimpeded Wireless Coverage in the Modern Warehouse

Poor wireless coverage is largely due to the very nature of what the warehouse was designed for: hold racks of shelving and equipment in a defined area with hallways and corridors. Warehouses have many obstructions because of how they’re designed. In addition to the physical obstructions, the sheer distance between items in a warehouse makes it challenging for traditional hardwired—and even most wireless—connections to reach all areas. Signals wane, and the potential for poor connection or outages is always present.

Additionally, many warehouses have multiple pieces of mobile equipment working independently. Providing coverage to workers on mobile equipment or the mobile equipment itself requires the ability to roam in and out of wireless coverage zones referred to as cells, very quickly. The previously mentioned shelving blockages impede communication or operation as the mobile equipment moves through various corridors. The need for overlapping cells and the ability to stay connected at all times is a constantly growing need, as devices and tools used in the warehouse space become smarter, mobile, and more precise.

The solution is networking re-invented. Rajant Kinetic Mesh®, the leading industrial wireless mesh network, provides warehouse-wide coverage, solving the multiple key issues plaguing all networking technology, coverage and range. Rajant Kinetic Mesh is fully mobile and intelligently adapts to change—instantly and without outside intervention—to keep mission-critical operations moving. Rajant Kinetic Mesh provides an extended range using multi-radio, peer-to-peer, machine-to-machine communication to maintain connections around obstructions and corners. Multi-radio is critical for any warehouse communications solution as it enables signal propagation without throughput degradation or loss inherent in all other mesh technologies.

Automating the Dangerous and Difficult

In addition to solving connectivity issues around and through traditional warehouse layouts, Rajant Kinetic Mesh ensures the automation of dangerous, complex, or repetitive processes involving autonomous platforms. Warehouse operations can be hazardous to personnel if not performed to safety standards. Yet, manual processes also create the risk of human error, resulting in costly inventory loss or, worse, putting workers in unsafe predicaments. Kinetic Mesh provides continuous connectivity for new applications that allow operators to keep personnel out of dangerous areas, augment worker productivity through automation, and optimize the accuracy of repetitive, high-volume tasks. This includes duties such as:

- Enabling autonomous and semi-autonomous guided vehicle and robotic mobility

- Automated inventory identification, data capture, and sortation

- Remote operation of storage, retrieval, and material handling systems to keep workers off the floor themselves

- Telematics

The continuous mobile connectivity provided by Rajant’s network can also be used for telemetry to monitor equipment health on demand and for real-time video to oversee worker safety.

With proactive insight into the status and performance of personnel and machines throughout the warehouse, operators can minimize disruptions, downtime, and danger to realize the true potential of a connected, automated warehouse.

How Rajant’s Mesh Network Works

The Rajant Kinetic Mesh network enables comprehensive warehouses coverage, solving the multiple vital issues that plague other networking options.

Rajant is unlike traditional networks; they are uniquely designed for environments and applications where client devices, and even the network itself, are in a state of constant change and motion. With Kinetic Mesh, warehouse operations can become more intelligent, more autonomous, and more mobile because the network itself is intelligent, self-optimizing, and uniquely able to support machine-to-machine (M2M) communications between equipment on the move.

To support environments with constant change and motion, Rajant uses a multi-frequency, multi-peer mesh connection to give every node in the network the ability to talk to each other using multiple radios simultaneously.

Each node, or BreadCrumb®, acts as a smart wireless device, maintaining connections to every other BreadCrumb that can be connected wirelessly or wired. This web of connections ensures that packets will always have a path home, can hold many connections over multiple frequencies simultaneously, and can be easily placed where needed to work around obstructions. With a complete array of form factors, lightweight nodes and OEM modules are available for deployment inside robotic equipment and on personnel working between the racks to readily extend coverage in the hardest-to-network areas. Radios affix to assets and people to become part of the infrastructure and can roam anywhere within the warehouse, proving a superior solution.

Radios act autonomously due to the underlying technology of InstaMesh® that dynamically optimizes performance as network characteristics change. Whether nodes are added or subtracted, frequencies are opened or blocked, or the assets are moved over large areas, Rajant Kinetic Mesh scales and strengthens. While InstaMesh leverages a proprietary algorithm, it is fully compatible with 802.11 standards. The protocol sends packages over Layer 2. If your voice, video, and data communications can be sent over Ethernet, it can be sent over the Kinetic Mesh network.

Warehouses having multiple pieces of mobile equipment working independently and employees on-the-move, all have the ability to roam without interruption. The previously mentioned metal shelving blockages impede traditional Wi-Fi and LTE communication as the mobile equipment moves through various corridors. The need for overlapping cells and the ability to stay connected at all times is a constantly growing need that Rajant provides.

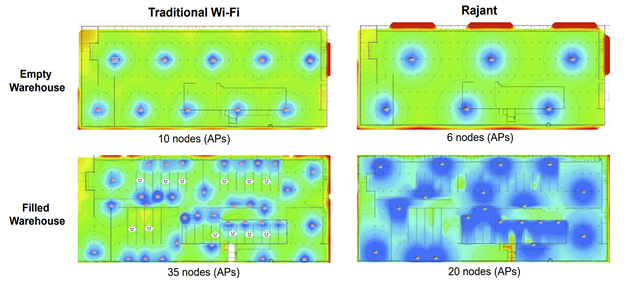

Since warehouses are not all open spaces, the racks, boxes, and equipment within them cause blockages for all RF signals. This quickly turns a 10 Wi-Fi node warehouse into a 34 node warehouse as corridors need coverage for devices, like hand scanners or mobile equipment fleet management systems. The traditional Wi-Fi solution is to add more Access Points with standard Wi-Fi range, nothing else. Each of these APs will be hardwired with Ethernet or fiber optic cable, making each new node more expensive and time-consuming to deploy.

In a Rajant Kinetic Mesh, only a few nodes need to be wired into the local area network. By wiring a few nodes, Rajant utilizes its proprietary protocol, Automatic Protocol Tunneling (APT), to separate the wired and wireless infrastructure or LAN/WAN. APT is a wired protocol that allows for multiple nodes to be connected into the same subnet while providing loop prevention and thus allowing for multiple LAN ingress points for information flowing inside the warehouse to the wired network in the building.

Why Rajant vs. Wi-Fi?

What are the factors that make Rajant Kinetic Mesh a superior choice? Several factors give Rajant BreadCrumbs an advantage on radiation cell sizes compared to traditional Wi-Fi. First, Rajant BreadCrumbs utilize a more powerful isotropic radiated power (EIRP) than conventional Wi-Fi. This means each radio card has more power out, giving each radio greater range. Rajant radios have a max transmit power of 28dBm. Understanding that adding 3dBm doubles transmit power out, compared to a Wi-Fi product with a maximum transmit power level of 22dBm, there is a clear difference in the power levels.

The standard antennas utilized by Rajant are yet another reason Rajant can provide more excellent coverage. Rajant standard antennas are 5dBi for 2.4 and 6dBi for 5.8. Compare this to a traditional integrated antenna in standard Wi-Fi access points of 1-2dBi. This 4dBi extra antenna gain provides additional range while maintaining higher data rates. The effects of higher EIRP seen below are calculations done using Tamograph, an industry-standard Wi-Fi predictive coverage application.

.png)

Rajant is a reliability-based mesh networking system, using InstaMesh protocol, built around providing wireless service in the world's most demanding areas. By using the mobile assets, increased range, rapid deployment, and the ability to simultaneously function as a backhaul and access point, Rajant can achieve a multifunctioning, robust, rapidly deployable, self-healing, Kinetic Mesh network indoor, outdoor, above ground, and underground.

About Geoff Smith

Geoff Smith is Executive Vice President of Global Sales and Marketing for Rajant and focuses on the company’s global expansion. He overseas multiple teams to ensure partners and end-user companies understand how the breadth of Rajant solutions can help achieve strategic advantages in their respective market.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product