The new maxon site in Beynost (15 minutes from Lyon) required a €10m investment of the maxon Group's own funds, and is located at the heart of a center of excellence for mechatronics.

Opening of the New maxon Mechatronic Production Centre

Opening of the New maxon Mechatronic Production Centre

Article from | maxon group

In late September, maxon France inaugurated its dedicated mechatronic production and innovation center with some key players from its ecosystem: customers, country subsidiaries of the maxon Group, the Swiss Ambassador, and the Swiss Consul General. We look back on a few intense weeks for all the maxon teams in France.

A new mechatronic Innovation and Production Center in France

The new maxon site in Beynost (15 minutes from Lyon) required a €10m investment of the maxon Group's own funds, and is located at the heart of a center of excellence for mechatronics. It is dedicated to:

- The design, development, and production of customized mechatronic systems and modules

- The production of motorized multi-axis systems for applications such as laboratory equipment and autonomous robotics (smart multi-axis systems)

- Distribution of multi-technology drives and accessories (the MDP range), including a selection of products for industrial automation

The Swiss family-owned Group is investing in developing its operations in France, where it aims to achieve turnover of EUR 40 million by 2030.

To accomplish this, maxon France plans to extend the international reach of French expertise in mechatronics for drive systems, in particular by exporting its expertise in the design and production of multi-axis drive systems aimed at laboratory equipment, autonomous connected logistics, and Industry 4.0.

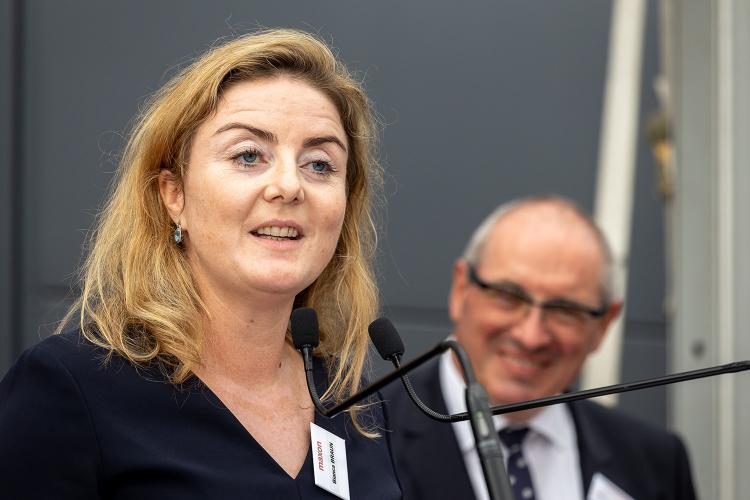

Bianca Braun, co-owner of the maxon Group at the opening of maxon France in September 2021 with Alain Pontille, CEO maxon France in the background

“maxon France is an important step in our development as a producer of high-tech drive systems. Establishing a long- term facility in France is a real opportunity.

We at maxon believe in our future, and we invest in it every year. Over the last four years we have invested more than 100 million euros in production facilities like the maxon France site. We must always keep moving forward. I am delighted to be here today to celebrate maxon France with you, and to be able to develop motion intelligence for your applications!” said Bianca Braun, co-owner of the maxon Group, who came to support the initiative of Alain Pontille, CEO France.

The company will also ramp up recruitment in order to achieve this goal, doubling the headcount at its French subsidiary from 50 to 100 employees by 2030.

Ultimately, the development of maxon France and the creation of its subsidiary in Beynost in the Auvergne Rhône-Alpes region will open up many opportunities for the French market:

- Better conditions for the development of mechatronic innovation projects

- Long-term establishment of offerings and services for motion intelligence for innovative French industries and companies

- Opportunities for collaboration with European institutions and universities for the development of mechatronic systems and for high-volume or high-risk projects

Inauguration in the presence of the Swiss Ambassador to France

“I am happy to be here, because this company provides a very solid example of Franco-Swiss collaboration. Investing in France is investing in the future, and Switzerland is the second-largest investor in France. maxon embodies this partnership perfectly: high technology, finding expertise, and combining them to produce added value and prosperity. This maxon France site shows that innovation, which stems from many collaborations and partnerships, can be achieved through local, regional, national, and international cooperation between the public and private sectors,” said Roberto Balzaretti, Swiss Ambassador to France.

Technological exchanges and meetings

maxon France used this day to invite selected customers from different business sectors for a technological tour of the company: the mechatronics production workshop, the mechatronics design department, and special arrangements for quality management, stock management, and shipping required for the production of customized mechatronic systems.

More than 30 of maxon France's customer companies attended this event. Some of them also demonstrated their applications in front of an audience that included Roberto Balzaretti (the Swiss Ambassador to France) and Pascal Bornoz (the Swiss Consul General).

- XSun, solar drone powered by maxon motors

- Vitirover, sustainable autonomous vineyard robot powered by maxon technologies

- The Smart ArM team from Sorbonne University, who designed and developed a prototype for a motorized bionic arm prosthesis. This French team, supported by maxon France, also represented France at Cybathlon 2020, showcasing the creation of mouvement powered by maxon technologies.

Another highlight of the day was the presentation of the Global maxon Academy, whose purpose is to educate both maxon employees and customers about the technology of mechatronics. All the participants enjoyed this very friendly approach to technology sharing.

maxon France aims to spread this knowledge of mechatronics throughout its ecosystem: customers, suppliers, universities, etc. in order to generate industrial momentum for mechatronics throughout the country.

This action will be further leveraged by the work of the Swiss Chamber of Commerce in France, of which maxon France has been an active member for several months.

Focus on the 1st National Convention of the Swiss Chamber of Commerce in France (CCSF) on the theme of “Innovation: a shared ambition of France and Switzerland”

A creator of connections and conversations between Switzerland and France since 1919, the Swiss Chamber of Commerce in France is a business organization that operates in three main areas: the economy, culture, and training. The CCSF gathers and mobilizes Swiss companies in France around stakeholders in the country to promote their establishment and development, and favorable conditions for their operation.

On September 16, the Swiss Chamber of Commerce in France partnered with the Swiss Consulate General in Lyon to organize its first national convention. Hosted by Mr. Pascal Bornoz at the Residence of the Swiss Confederation in Caluire-et-Cuire, its theme was “Innovation: a shared ambition of France and Switzerland.”

maxon France receives the CCSF 2021 Award

On this occasion, as a Swiss company operating in France, maxon France received the CCSF 2021 award from the Swiss Ambassador to France, Roberto Balzaretti. One of the main reasons for this award was the company's outstanding performance in the Mars mission, with the Perseverance rover and its little helicopter Ingenuity (maxon motors have equipped every Mars mission since 1997). Another was the opening of the new maxon France production site (a €10m investment), a symbol of Switzerland's great industrial potential in France.

maxon's commitment to CCSF

2021 marks the beginning of maxon France's official membership of the Swiss Chamber of Commerce in France. With numerous mechatronics companies active in the Auvergne-Rhône-Alpes region, maxon France (actively supported by CCSF) favors the exchange of best practices with other Swiss manufacturing and motion companies in France, to stimulate industrial synergies.

For more information, visit: https://www.ccsf.com/convention-nationale/

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Automate 2025 Q&A with maxon group

Understanding Torque and Speed in Electric Motors

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product