If you have added manufacturing robots to your facility, you are already aware of the advantages they provide and the ROI. Robots do have a downside, however, when it comes to programming—most of the time, they must be offline to be updated or programmed.

Why Use Offline Robot Programming Software and How to Get Started

Why Use Offline Robot Programming Software and How to Get Started

Article from | Robotmaster

One solution is to use Offline Robot Programming Software (OLP), which allows you to generate robotic code and then upload it to the robots without any downtime. Since it’s important to choose the right OLP solution, let’s take a look.

Why use Offline Robot Programming Software

What is Offline Robot Programming Software?

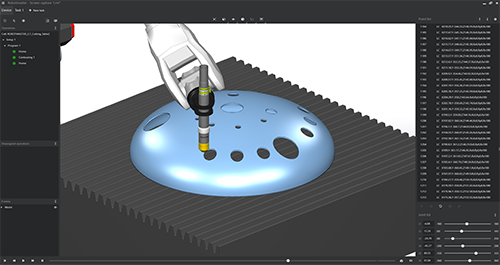

Many business owners are unaware of the advantages OLP can provide for their business or how to learn more. OLP software works with 3D CAD models to define tasks such as path planning, programming, and engineering. Once the robot code is generated it’s then uploaded to the robot.

One of the challenges with OLP is it can seem intimidating to users, who may have tried earlier versions and are unaware of how far the software has evolved and improved. The good news is OLP has evolved rapidly in the last 4-5 years, and it has become more user-friendly and intuitive.

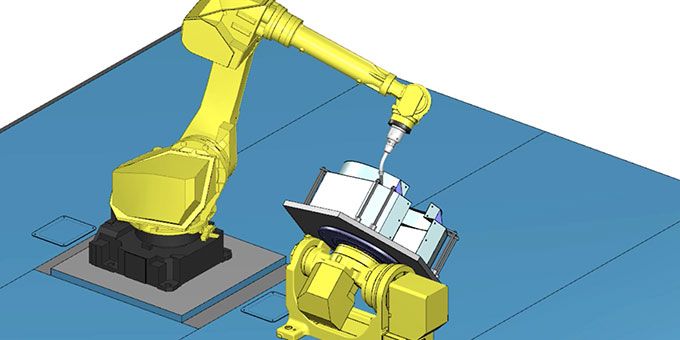

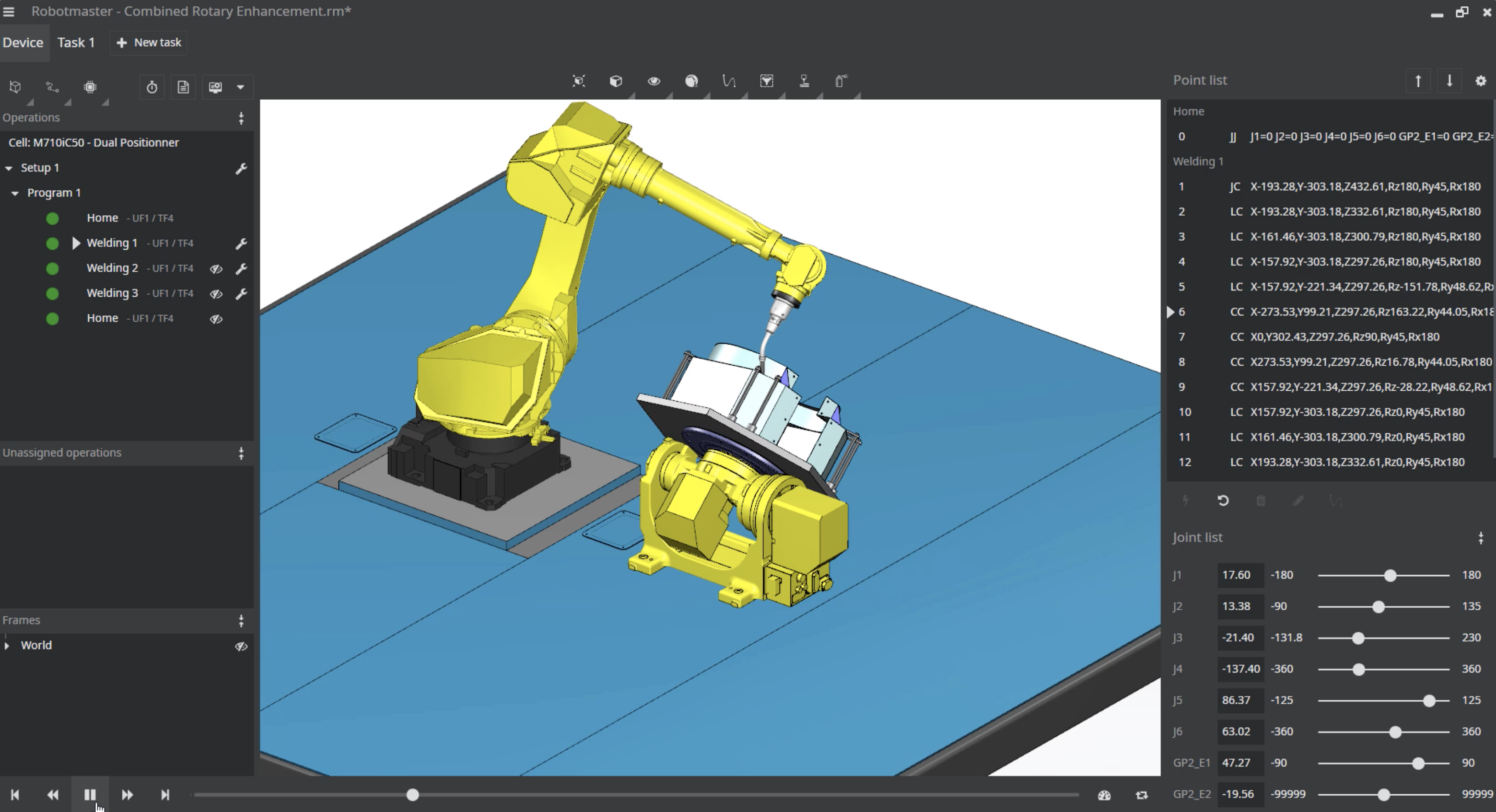

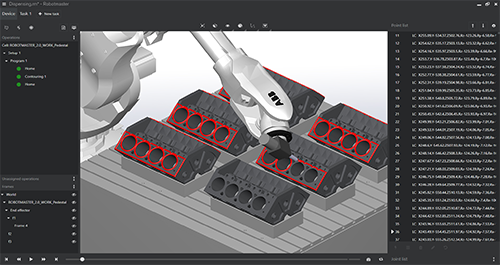

The OLP environment utilizes a 3D CAD model of the robot work cell. All the programming is completed in the virtual space using either OEM or 3rd party software, which allows for troubleshooting and problem solving before the robot has been installed. Programs can be created, simulated, and edited in the OLP environment, ensuring that the robot will perform as required once it is installed. OLP is particularly helpful in ensuring the right size robot is selected for the application allowing first time buyers rest assured they have the right robot for the parts.

A manufacturer can program all the tasks as they finish building the automation, resulting in a “plug and play” installation that can save days or weeks from the final design installation. New programs can be created offline and uploaded to the robot, without interruption to the current program that is running. Whether integrating a new robot system, or redeploying an existing one to new tasks, OLP allows for greater return on investment, with little downtime and less unanticipated issues.

Offline Robot Programming Software works in simulation, using a 3D CAD model of the robot workcell.

Key advantages of OLP

- Quicker robot integration: Whether a new installation or a redeployment, time is always an essential factor. By creating, adjusting and testing the programming in a virtual environment, when the robot is installed, it is ready to operate, saving days or weeks compared to a teach pendant.

- No downtime: With teach pendant programming, the robot must be in teach mode. OLP can upload the programming to a robot while it is operating, which means less manufacturing delays.

- Safety: Whether faced with a safety concern due to robot configuration, or restricted access to the robot due to work from home protocols, OLP can be completed from a laptop in a safe location, and uploaded to the robot without the need to access the teach pendant. In addition, OLP allows for pre-engineering of the robot cell, providing the ability to implement the entire work cell, with fencing, external axis and other components to avoid delays at the time of installation.

- Quick changeovers: OLP can program a robot for Part B, while it is completing the Part A run. As soon as Part A is complete, the Part B programming can be uploaded and the task begun, without turning off the robot. OLP allows for quicker cycle times, allowing for a higher mix of jobs with faster transitions.

- Universal application: Few manufacturing operations ascribe to brand loyalty, operating only one brand of robot or other tools. For most, the robot that accomplishes the task at the best price is the one that is installed, which leads to a variety of robots that need to be programmed. True OLP software should be “robot agnostic”: it has the ability to communicate across many platforms. Even if you are redeploying an older robot, OLP will interface with it.

- Test new configurations: Adding a robot into your manufacturing operation is a significant capital investment. Robotmaster’s intuitive user interface allows the user to design and test various configurations in 3D simulation before the robot is installed. You can engineer, identify, and solve issues before the robot arrives.

- Ease of use: The right OLP requires process knowledge, however, it does not require advanced programming or robotics expertise. OLP is built around the user and is designed to be a clean and elegant user experience. In addition, the ability to interface with various brands of robots, your programmers do not need to learn proprietary OEM interfaces for each OEM robot brand.

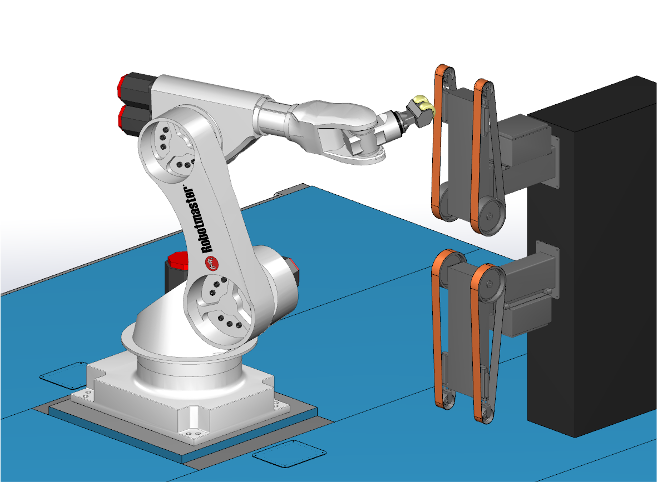

OLP can upload the programming to a robot while it is operating, which means less manufacturing delays.

How to choose the best OLP software

- A very effective way to inform your decision on whether OLP is right for you is to engage your community of programmers, shop owners, integrators and other manufacturers to discover why they use the software they do. Most are happy to share their experiences and why the solution they have does or doesn’t work for them.

- Look for an OLP software provider who has deep process knowledge in solving robotic programming challenges, such as welding, deburring, additive manufacturing, cutting and trimming, dispensing and other applications.

- With OLP software, one size does not fit all. If you’re a manufacturer that has made the decision to be exclusive with one robot brand then the OEM software might be the right solution for your operation.

- Ask for a test drive of the software you are considering, to ensure fit for your operation and ease of use. Try out their support line. The solution should check all the boxes for the applications for your facility, but also possible future ones as your operation expands.

- Like any capital purchase, software has a cost. Ensure you understand the expected ROI, the maintenance costs, and costs for add-on processes, such as welding. Normally training costs are a consideration in calculating ROI, but with today’s OLP software the simplicity has reduced those dramatically.

- OLP solutions are not for everyone, so it’s important to work with a reputable software integrator who can help you make the best decisions and provide you with any assistance you need along the way.

Look for an OLP software provider who has deep process knowledge in solving robotic programming challenges

At Robotmaster, since 2001 we have been taking great pride in creating intuitive, easy to use Offline Robot Programming software with a team of professionals that understands manufacturing and design, kinematics, mathematics optimization, simulation and CAD/CAM. Hypertherm is 100% employee owned, with over 1800 associates.

Learn more about Robotmaster OLP Software

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Robotmaster

Robotmaster, a Hypertherm Associates brand, is an offline, is an offline robot programming software that helps manufacturers maximize their robot's productivity with easy and efficient robot programming for a variety of applications such as cutting, trimming, milling, welding, spraying, polishing, sanding, grinding, deburring, and more. Robotmaster uses integrated CAD/CAM functionality to make robotic programming easy and intuitive for everyone, even first-time users.

Other Articles

Have You Looked at Automating Fabrication Tasks in the Past? Why Didn’t You?

Trane® Saves Over 80 Hours of Robot Programming Time

3 Benefits of Working With a Robotic Integrator

More about Robotmaster

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product