With AI-powered SORT systems, robots do the mundane, repetitive tasks, successfully piece-picking customer orders into completion. Thus, our customers can redeploy employees in more suitable roles throughout the supply chain.

AI-powered SORT systems in E-Commerce Fulfillment

AI-powered SORT systems in E-Commerce Fulfillment

Q&A with Marin Tchakarov, CEO | Kindred

Tell us about yourself and Kindred.

Over the last couple of decades, my career focused heavily on technology and the Internet of Things (IoT). Now, as Kindred CEO, I work with the team and Ocado Group’s Leadership to deliver on the promise of industry-progressing artificial intelligence (AI), machine learning and next-generation robotics systems for supply chain and order fulfillment organizations.

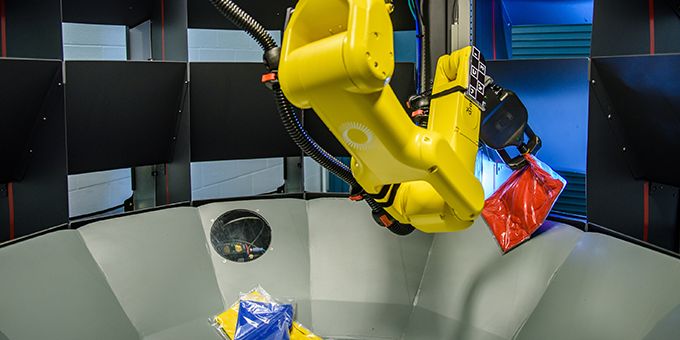

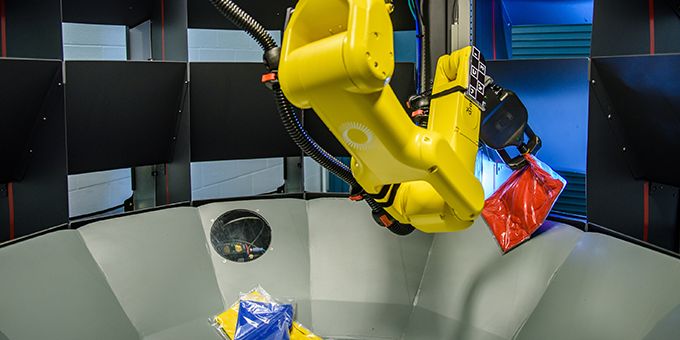

Kindred is more than a robotics and AI company. In 2014, the company set out on a mission to augment human labor with AI robot partners to fully innovate e-commerce fulfillment operations. Today, with increased labor complexities in e-commerce fulfillment centers, customers automate their fulfillment and supply chain operations using Kindred’s AI-powered, piece-picking SORT robots to increase throughput and efficiency.

Kindred’s cutting-edge technology is powered by our proprietary platform AutoGrasp™. Our platform integrates machine vision, grasping and placement technology to create autonomous solutions for complex, real-world commercial problems. Our team of engineers and business operators continues to set the new standard of reinforcement learning for robots.

How has COVID-19 impacted your business, for the positive or negative?

The COVID-19 pandemic was a catalyst for Kindred’s growth. As a direct result of the pandemic, e-commerce sales have grown exponentially, contributing to a larger percentage of retailers’ revenue than ever before. To meet the increased e-commerce demand, brands like Gap Inc. and American Eagle Outfitters have turned to automation solutions, more than tripling their existing Kindred SORT robot fleet.

Kindred’s SORT solution enables natural social distancing in fulfillment centers. One associate works alongside three-to-four SORT robots simultaneously, keeping up with e-commerce order fulfillment while maintaining social distancing protocols.

Kindred’s SORT piece-picking robots help alleviate human workforce challenges, which the COVID-19 pandemic has only exacerbated.

What is your response to concern over robotics and AI and their role in eliminating blue-collar jobs?

With AI-powered SORT systems, robots do the mundane, repetitive tasks, successfully piece-picking customer orders into completion. Thus, our customers can redeploy employees in more suitable roles throughout the supply chain.

When visiting customer sites, we have heard distribution center employees referring to SORT machines as “their” robots. Some name them, talk about personality-like aspects of the robot they work with, and all of them show their pride in working alongside these sophisticated machine partners.

Due to that rapid growth in e-commerce fulfillment, especially with the impact of COVID-19, retailers simply cannot find all the people they need to staff their fulfillment teams, and automation solutions like ours continue to fill those ever so widening gaps.

What role do humans play in the context of Kindred’s products?

Traditional manual putwall stations are extremely labor-intensive and hands-on. Workers are side-by-side, experiencing multiple physical contact points with each other and inventory items. With Kindred’s AI-powered SORT systems, the robot picks and places items into the bins for customer orders, taking over this repetitive, mundane task. The human worker then works side-by-side with our technology to pack complete orders for shipping.

While SORT robots are over 99% autonomous, they still require humans to collaborate with them. Kindred’s human-in-the-loop methodology provides 24/7 supervision to watch over the entire network of robots and troubleshoot any potential exception handling and item set issues that may arise.

You’ve recently become part of the Ocado Group. What does this mean to Kindred’s business going forward?

Ocado Group, the leading online grocery platform and solutions provider, recently completed its acquisition of Kindred. With the infusion of resources, Kindred will accelerate delivery, increase innovation and grow faster, and introduce robotic solutions to new markets outside of grocery.

Our commitment to solving increasingly complex customer problems using intelligent machines uniquely aligns with Ocado’s product roadmap, culture and values.

Ocado’s acquisition of Kindred gives us more resources to grow faster. We’re focusing on four key areas of expansion:

-

Investing in technology development to expand the kinds of items Kindred solutions can handle.

-

Expanding into additional market segments that both existing and future customers will find appealing.

-

Commercializing Kindred technologies into new geographies around the globe.

-

Scaling our customer success team’s capabilities, offering enhanced business intelligence to Kindred customers and our Ocado teammates.

Does Kindred have any plans to expand outside of the U.S.? What about different industry verticals?

Kindred will expand the types of items our robotic solutions can handle, thus opening up opportunities for applications in grocery, general merchandise and other non-deformables (i.e., rigid) item sets. Over the next few years, we plan to focus on multi-national expansion.

Look into the future a few years, what does an e-commerce warehouse look like and what role is Kindred playing in that?

After a year of unprecedented disruptions and growth, we expect four key e-commerce warehouse trends to continue:

-

The explosive growth in e-commerce sales will sustain in 2021 and beyond.

-

The need for safety guidelines and social distancing in fulfillment centers will continue into 2021, driving demand for automation and innovation. Kindred’s SORT robots are uniquely suited for employee safety and social distancing. One employee can manage three-to-four SORT systems at a time, effectively tripling the efforts of fulfillment labor and overall throughput, while minimizing interaction between employees.

-

Human-robot collaboration will be increasingly important to ensure optimum efficiency and throughput. Labor shortages and the desire for automation are still very relevant business challenges – today and in the future.

-

Redeployment of human resources will continue to be an emerging trend, as organizations utilize automation for mundane, repetitive tasks and place people in more suitable roles throughout their supply chain.

About Marin Tchakarov

Marin Tchakarov is Kindred’s CEO. Prior, he served as interim CEO as well as COO and CFO. In his role as CEO, Marin works with the Kindred team and Ocado Group’s Leadership to deliver on the promise of industry-progressing artificial intelligence, machine learning, and next-generation robotics systems for supply chain and order fulfillment organizations.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product