In millions of years of evolution, nature has produced many sophisticated locomotor systems that engineers use as inspiration for creating better robots. We show some current technical developments that are highly advanced.

Fauna Robotica

Fauna Robotica

Contributed by | maxon motor

Reprinted with permission from the maxon drive.tech blog:

The bionic bird

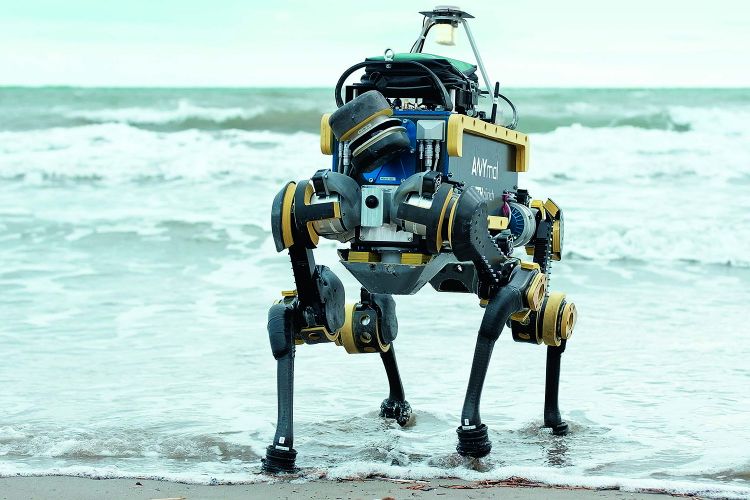

ANYmal

The underwater snake

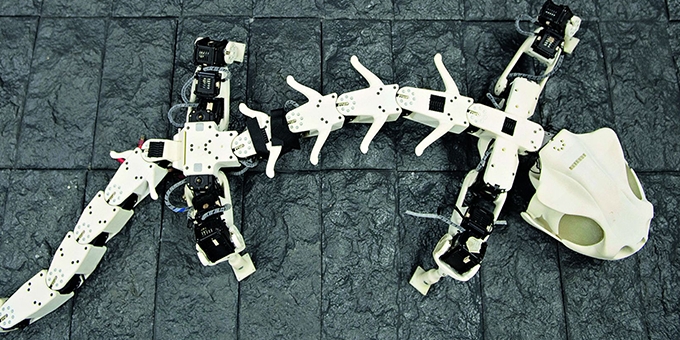

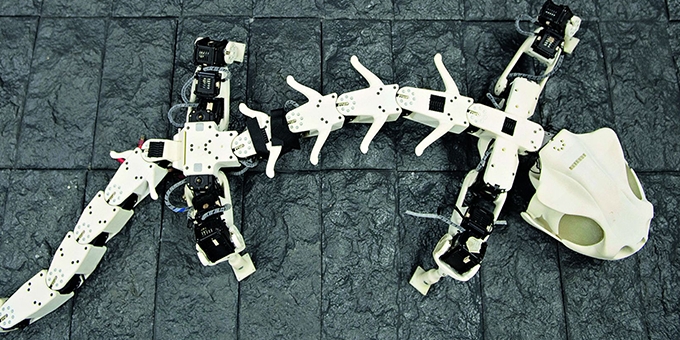

The robotic snake

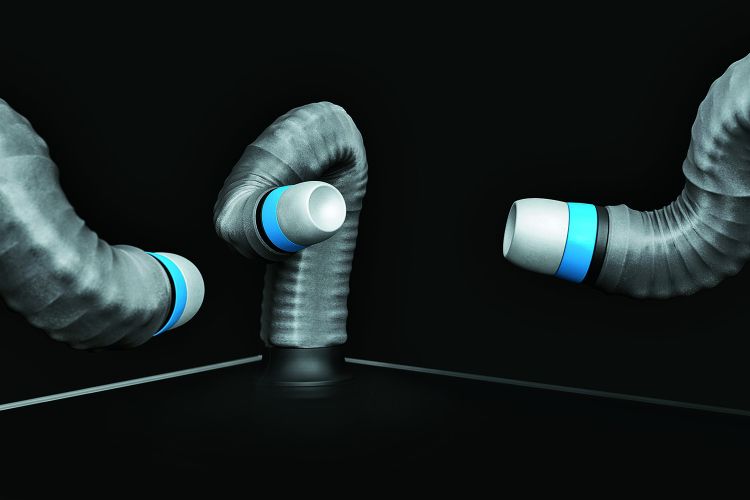

Octophant

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Automate 2025 Q&A with maxon group

Understanding Torque and Speed in Electric Motors

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product