The latest addition is a small crawler robot that magnetically "sticks" to metal walls and is able to move in all directions. It carries cameras, sensors and tools for inspection or maintenance work in tight pipes and on the outer hulls of tanks or ships.

These Robots Crawl Into Every Nook and Cranny

Contributed by | maxon motor

Reprinted with permission from the maxon motor drive.tech blog:

It started as a project by two engineers who were close to retirement. Today, the modular inspection robots by Canadian company Inuktun are successfully in use all over the world – defying even the most adverse conditions.

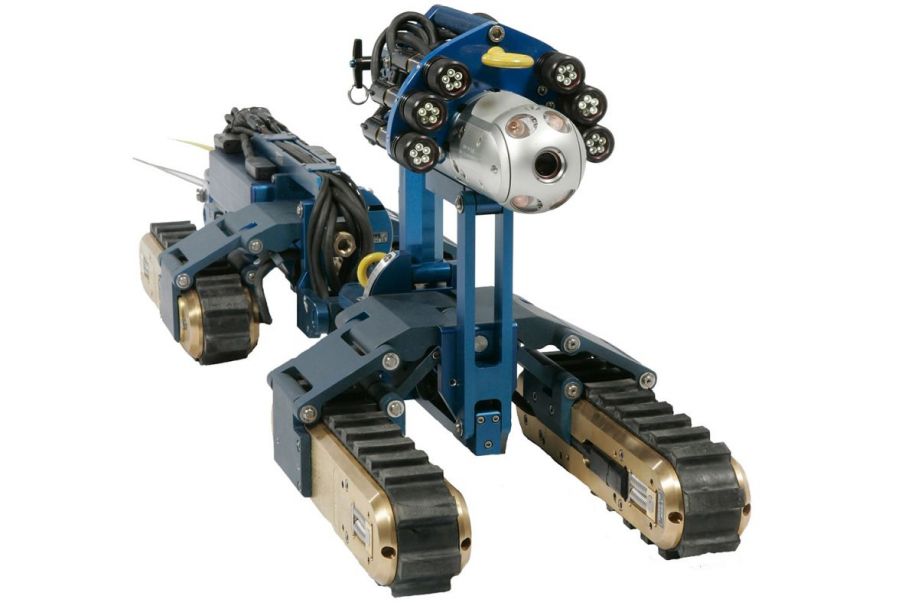

Inuktun's Multi-Mission Modular (IM3™) robot family just keeps growing. The latest addition is a small crawler robot that magnetically "sticks" to metal walls and is able to move in all directions. It carries cameras, sensors and tools for inspection or maintenance work in tight pipes and on the outer hulls of tanks or ships. The robot named MiniMag is able to operate both in air and under water. It can also be equipped with additional components from Inuktun or third-party manufacturers.

Where humans cannot reach

The Canadian company produces more than 100 camera and crawler systems per year, as well as components. The remotely operated vehicles (ROV) are successfully used all over the world for inspection and maintenance work. They can reach places that are inaccessible to humans due to space confinements or hazards. The systems are resistant to the harshest ambient conditions. They are often used for applications in the oil and gas, petrochemical, nuclear and mining industries. Inuktun's small inspection robots were also utilized after the 9/11 attacks in New York in 2001, and after the tsunami in Japan. There are many more areas of application, but "we simply cannot talk about certain applications," says Priscilla Johnson who is responsible for marketing at Inuktun. "Our team always looks forward to developing special solutions for new challenges. Especially in cases where several requirements are combined."

Modular system as success recipe

Back in 1989, Terry Knight and Al Robinson, the founders of Inuktun, probably didn't expect they'd be this successful. At the time – both of them close to retirement – they began designing small swimming ROVs. Today, more than 50 people work at the Inuktun headquarters in Nanaimo. The company has several sales companies and partners all over the world. And the market for industrial inspection robots is growing continually. But so are the requirements. Customers are increasingly demanding solutions that cover several fields of application.

That is why Inuktun makes use of modular technology. It allows customers to specifically configure the perfect robotic solution for their needs from a large selection of proven cameras, crawler elements and controllers. When requirements change, new components can be added to the system or it can be completely reconfigured. The company also offers a wide range of rental robots – with increasing success. Priscilla Johnson explains: "In some cases customers cannot afford to buy a robot system. Existing customers, on the other hand, may have a special application for which their equipment is insufficient. With a rental system they are able to close the gap."

The robotics specialist Inuktun uses components from Swiss drive specialist maxon motor. All crawler modules and cameras are equipped with brushed maxon DC motors, using various motor-gearhead combinations. "We prefer maxon drives because they are efficient and silent," says Johnson. maxon products are regularly used in difficult conditions, for applications such as deep drilling, underwater robots or rocket launches. For its sophisticated robots, Inuktun needs precisely this kind of reliability and quality. All the more since, in future, these robots are to perform their tasks autonomously.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

maxon group

maxon is a leading supplier of high-precision DC brush and brushless servo motors and drives. These motors range in size from 4 - 90 mm and are available up to 500 watts. We combine electric motors, gears and DC motor controls into high-precision, intelligent drive systems that can be custom-made to fit the specific needs of customer applications.

Other Articles

Automate 2025 Q&A with maxon group

Understanding Torque and Speed in Electric Motors

How Parvalux Is Helping to Develop the Next Generation of Conveyor Systems

More about maxon group

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product