Robotic welding design from the ground up.

Robotic Welding 101

Contributed by | Güdel Inc

Before shop managers install a robotic welding and joining system, they should understand its components, their functions and how they relate to welding applications as well as general robotic automation tasks.

Advanced intelligence

Controls, communication instruments and operator interface components are interrelated, critical components in automation systems. System controls include both the robot controller and other system controllers such as PLCs and PCs. Generally, robot controllers are tasked with directing robot tooling and providing robot motion, while system controllers provide logic through inputs and outputs for events such as parts movement, communication to the production environment, system data acquisition and human interface.

The operator interface provides a window into the workings of the various controllers. It is how plant personnel see system status and is the means to input any externally initiated process modifications. Considerations in operator interface designs include the level of human involvement with the system, technician skill levels, any desired part quality input decisions before the robot processes them and desired notification when the system requires operator intervention.

Other critical assemblies include safety system components, such as personnel barriers, access doors, door switches, awareness beacons, control system interlocks and signage. Peripheral equipment such as a robot riser or mounts, turntables and conveyors for part presentation, part fixtures, tooling and nests is all part of the robot-based automation system that helps connect the robot to its environment, including incoming/outgoing product.

Getting granular

While top-level systems such as controllers and interfaces provide the brain power and communications for a robotic welding workcell, the individual components are what bring the workcell to life. Pneumatic components such as valves, fittings, air filters and pressure sensors are used for gripper actuation and vacuum generation. These components are either on the robot tool, as in material handling, or necessary to actuate part-holding clamps and vacuum hold-downs for welding.

Discrete sensors help the robot and other systems to monitor the progress of motion control and handling systems by verifying action and locating parts, for example. A pick-and-place application may use a presence sensor to determine when a part is in the proper pick position and another sensor to confirm that the gripper is open and ready to pick up a part. When the robot moves to the pick position, a gripper sensor confirms that the gripper has closed on the part, and a part presence sensor on the tool indicates that a part is in the gripper.

Welding System-Specific Components

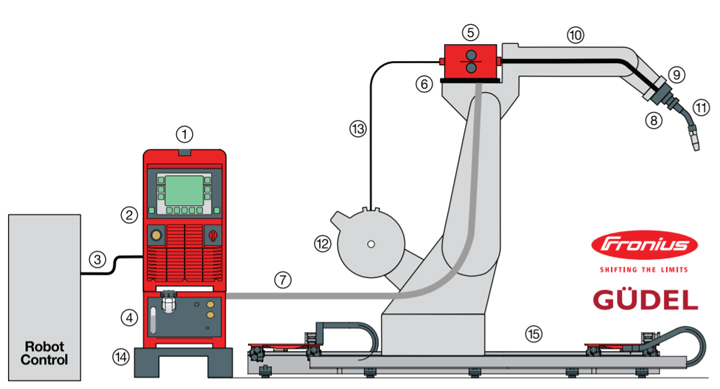

- The welding power source is the heart of the welding system. It provides the necessary power to generate the heat to liquefy the metal at the end of the torch so that the metal parts are joined (welded) together.

- The interface allows the robot controller and the welding power supply to communicate. This constant communication monitors weld performance and modifies parameters that affect weld quality, such as robot weaving and speed.

- The interface communication cable connects the welding power source to the robot controller.

- For welding that requires a water-cooled torch, a water cooler is required. Coolant lines need to be connected and dressed externally to the robot arm.

- The wire feeder supplies the weld wire to the torch for the welding process, and it needs to be matched to the voltage and current capability of the welding power supply.

- The wire feeder bracket mounts the wire feeder to the robot and provides insulation.

- The hose package contains the wire feeder communication cable, positive or negative lead for the self-shielded wire, shielding gas hose and coolant lines if needed.

- A torch breakaway, or collision box, mechanically disconnects the torch in the event of a collision.

- An insulation disc is required between the torch or any mechanical breakaway and the tool mounting plate on the robot.

- A torch cable, or whip, connects the torch with the wire feeder and provides the connection for the torch tip use.

- The torch neck, or gooseneck, is the actual welding torch.

- The weld wire holder supplies the bulk wire to the wire feeder for consumption in the welding process. Typical weld wire holders are either a spool type or a barrel.

- The weld wire conduit, installed between the wire feeder and the welding wire holder, provides the conduit for the wire to travel to the wire feeder.

- The power source stand is used to mount the welding power supply.

- Linear tracks allow the welding robot to extend its reach, performing the work of multiple robots. Not shown in the diagram is a torch-cleaning station, which is required because a robot-based welding system typically must work at or near maximum speed and therefore has little time to recover between welding operations. Cleaning and trimming the wire properly to the correct protrusion ensures that each weld starts with the optimal conditions to produce a quality weld and part.

Automation systems will always require electrical components, too, such as connection boxes, transformers, motor starters and external axis motors and drives, along with the required safety system controls.

Even the most basic components in a robot workcell are critical to uptime. Cables fixed to the robot arm, known as dressing, must be high flex and routed to accommodate full robot motion. Power drops, cables between system components and connection boxes are stationary, so they do not require high-flex cables. Dressing also includes other items mounted on the outside of the robot arm, such as pneumatic lines, cooling waterlines and material-dispensing hoses. Dressing for welding includes the torch cable, hose package, weldwire conduit and any sensors that run outside the robot’s arm.

Expand the work envelope

The last component to consider in a robot-based welding system is the actual robot and its supporting platform. Robots are generally chosen based on three criteria: reach, payload and speed. In welding applications, the robot’s payload must be rated to handle the torch, breakaway, insulating disc, wire feeder and torch cable load on the arm. The robot’s range must be enough to articulate and reach all the required weld points on the parts. The robot controller requires welding software that provides the means to communicate to the welding power supply and interpret the need for motion changes to optimize the welding process. The production rate required must include the robot’s speed in performing all the welds on the part plus its air movements.

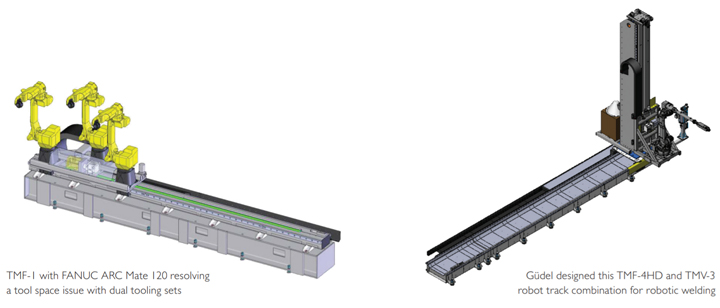

For some welding applications, often large or high-throughput applications, a single robot mounted on a track can perform the work of multiple robots. For example, in a welding system the robot can be mounted overhead or on a standard floor track. Both options offer the ability to expand the work envelope and articulation of the robot to access hard-to-reach locations while also allowing the user to process larger parts that formerly required multiple robots. In a welding system, consideration must be given to protecting the track mechanism and cabling from sparks and hot weld flash. The Güdel Track Motion Module design utilizes an Armoloy coating plus a set of brass rail scrapers that, coupled with the Güdel Rollers, keep the critical track components clean and operating flawlessly, while covers installed on the cable trays and E-chain prevent weld sparks and hot flash from damaging the wiring. Additionally, consider mounting the robot controller, welding power supply and wire holder on a second carriage linked to the robot carriage or on a shelf designed for this equipment so it travels with the robot while performing the work. With some system planning and correct equipment specification, welding is a perfect application for robots on Güdel Track Modules. Regardless of the application — welding or other — many of these components and functions are common to all systems. Controls, communication devices, operator interfaces, sensors, peripheral equipment, parts handling equipment, fixtures, safety features and cable management devices are common components in all robotic workcell solutions.

There is a final component that cannot be overlooked: people. Many robot workcell tasks cannot be automated, such as project management, system simulation and layout, system development, design, programming, proof-of-concept testing and system mock-up.

About Güdel Inc.

Güdel Inc. is the US subsidiary of Güdel Group, a global manufacturer of robotic automation products, systems and services. Güdel supplies linear-motion modules, robot track motion units, gantry robots and components to OEMs, systems integrators and machine builders serving the automotive, aerospace, logistics, heavy industrial and power generation industries. Güdel Inc. is located in Ann Arbor, Michigan, in a dedicated 45,000-square-foot facility, providing North American customers with engineering, design, production and customer service support.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product