TM Robotics will be announcing the newest 6-axis robot from Toshiba Machine. Customers are looking for light to medium duty robots to perform tasks, without breaking the bank.

Talking AUTOMATE 2017 with TM Robotics

Contributed by | TM Robotics

Your company will be exhibiting at AUTOMATE 2017, what is it that makes this an important event for your company?

AUTOMATE is the premier event in the robotics industry, so it’s extremely important that we be there. What’s great about this show is we can network with our partners, integrators, and potential customers all in one place.

What can a visitor to your booth expect to see this year?

TM Robotics will present the global launch of Toshiba Machine’s newest 6-axis robot, as well as exhibit several other robots in a variety of functional capacities. They include:

- The TVL500 6-axis and the THL300 SCARA working together to hold a golf club and putt, demonstrating how each robot can accomplish deliberate tasks that require attention to finite details.

- The TSVision3D software. This enables system integrators to easily automate 3D bin picking and is of great interest to industries such as food preparation, pharmaceutical, and order fulfillment.

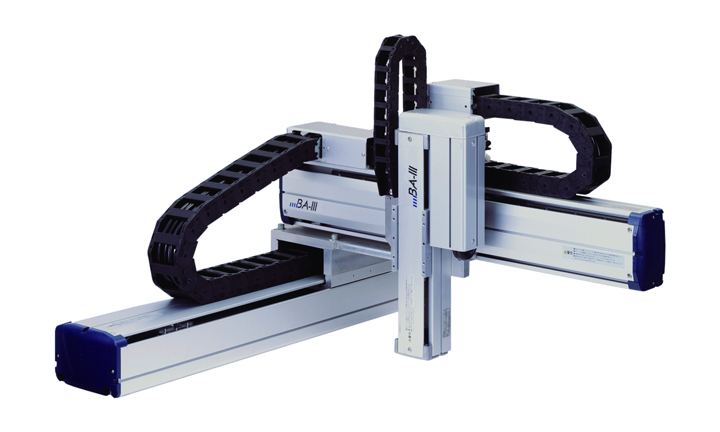

- The BAIII series Cartesian, which will be demonstrated with TM Robotics’ partner ECD to showcase the diversity of the range of actuators from Toshiba Machine.

- The TH550A SCARA will be showcased with TM Robotics’ new partner, ASG, in screw driver assembly applications.

Any new products you will be introducing?

TM Robotics will be announcing the newest 6-axis robot from Toshiba Machine. Customers are looking for light to medium duty robots to perform tasks, without breaking the bank. Toshiba Machine’s latest series was developed with that in mind. It provides significant cost savings, without sacrificing speed, repeatability, and reliability.

When you get a chance to walk the exhibit hall floor yourself, what is it you will be most interested to see?

We’ll be looking for new peripheral automation products, such as end of arm tooling (EOAT), that will enhance our offering to the customer and make the integration of our industrial robots even more user friendly and powerful than they currently are.

AUTOMATE 2017 has over 100 educational sessions, is your company involved in any of them this year?

We’re not involved in any of the sessions this year, but that doesn’t mean we’re not looking forward to a great show. AUTOMATE always ensures exhibitors and presenters have the ability to showcase their robot possibilities, which in turn assists manufacturers in gaining the most from their automation investments.

When you book a booth for a tradeshow like this what are your expectations and what does your company hope to accomplish at the event?

With this particular show, we have high expectations. But that’s only because of how well it’s done year after year. We come to AUTOMATE to connect with colleagues and customers, to learn from the many interesting sessions, and to demonstrate our vast robotics capabilities to all that attend.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

TM Robotics (Americas) Inc

TM Robotics, in partnership with Shibaura Machine, formerly known as Toshiba Machine until 1st April 2020, offers a comprehensive range of industrial robots ideally suited for high-precision assembly, machine loading/unloading and material-handling applications that can be dust proof, clean room, or IP65/67. The company's extensive product line starts with a Cartesian solution available in thousands of combinations from single actuators to four-axis solutions; six-axis solutions that can include precise vision-control; and a complete range of SCARAs from low cost to the industry-leading SCARA with 1200-mm reach that can carry up to 20 kgs. TM Robotics sells and services robots throughout Europe, the Middle East, India, Russia, and Africa, as well as North, Central, and South America, from headquarters in Hertfordshire, England and Elk Grove Village, IL, USA. For more information, visit www.tmrobotics.com or follow us on Twitter, LinkedIn and YouTube.

Other Articles

Giving lens cleaning cloths a robotic hand - Robotic automation for textile processing

Investing in the UK’s injection moulding sector - The case for all-electric machines and robotic integration

Robotic solutions for pharmaceutical packaging - Automated system addresses key limitations of manual processes

More about TM Robotics (Americas) Inc

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product