With manufacturers more and more concerned about being able to change product and component mix on the fly, they are demanding a more flexible feeder bowl solution that allows for changing component recognition without expensive and time-consuming retooling of the system every time.

RR Floody's Powerful New Flexible Feeder System Pairs Mitsubishi Electric Robot and Cognex Vision System

Contributed by | Mitsubishi Electric Automation, Inc.

Case Study

- Mitsubishi Electric F-Series 6-Axis Robot

- Cognex Vision System

- Highly adaptable vs. standard feeder systems

- Optimal combination of vision and robotics

- “85% out of the box” solution

- Fully integrated with industry-leading Cognex vision system

- Three year standard warranty

- Customizable with easy to integrate HMI and more

BACKGROUND

BACKGROUND

RR Floody Company Inc. creates factory automation solutions featuring multiple brands of robotics, vision systems, barcode readers, HMIs, sensors, safety devices and other equipment, backed by a range of in-house interfacing, design, programming and other support services. With more than 80 years of experience, the company prides itself on having “more applications engineers than sales engineers,” a testament to its strong focus on service and creating customized, practical, on-site solutions for every customer. In fact, for each project, the Rockford, Illinois based company works to define and optimize each customer’s four specific critical values, “Reduce My Risk,” “Make My Life Easier,” “Increase My Profitability,” and “Increase My Competitive Edge,” to help optimize the success of every application.

CHALLENGE

Vibratory feeder bowl systems — solutions designed to contain and properly orient components as they are automatically fed one by one into the next machine in an assembly line or similar process — are a mainstay of industrial automation, and have been workhorses in manufacturing facilities of all kinds for decades. Often meticulously designed to handle the geometry of a specific part, this built-in accuracy is increasingly becoming an expensive drawback for a growing number of applications. With manufacturers more and more concerned about being able to change product and component mix on the fly, they are demanding a more flexible feeder bowl solution that allows for changing component recognition without expensive and time-consuming retooling of the system every time. With requests from clients increasing, RR Floody sought to develop a highly effective, quickly adaptable, cost-efficient, out-of-the-box flexible feeder solution by selecting and expertly integrating the optimum automation products from their diverse portfolio of world‑class brands.

SOLUTION

The key to meeting this client need, according to RR Floody Applications Engineer Nick Parnello, was to add a programmable vision capability to the traditional feeder configuration — this would help give customers a nearly limitless ability to switch desired components in the feeding process. RR Floody brought together the equipment products that would give them the best results, and that, according to Parnello, would be a Mitsubishi Electric robot and a Cognex camera, “hands down.”

“Cognex vision systems have been the leaders forever and we find that their line is just far superior to anyone else’s. Their algorithms are extremely robust and they provide much more capability,” said Parnello. “And when it comes to quality and reliability, Mitsubishi Electric robots are beyond anything I’ve seen in 20 years in the business. They’re the only ones that come with a three year warranty standard, while everyone else just gives you one year. That really tells me something.”

However, Parnello notes, a perhaps even greater aspect of pairing the two products is their integrability. Due to the unique partnership between Cognex and Mitsubishi Electric, the Cognex vision system and the Mitsubishi Electric robot work together seamlessly right out of the box without the need for extensive customized programming, almost as if they were made by the same manufacturer.

Discussing some of the alternatives, Parnello explains a few of the benefits that this fact brings to RR Floody and its customers.

“If a distributor specifies a ‘same brand’ robot/vision solution using another brand, they don’t get the industry-leading, specialized vision capabilities of Cognex or the quality and reliability of Mitsubishi Electric robots, and that can provide a much weaker solution for the customer,” he said. “And if they specify a Cognex vision system with a different brand robot or a Mitsubishi Electric robot with a different brand vision system, they not only miss out on the benefits of one or the other, there ends up being a costly programming bill to get the pieces to talk to each other.

“The Mitsubishi Electric robot/Cognex Vision system combination definitely delivers the best of both worlds.”

RESULTS

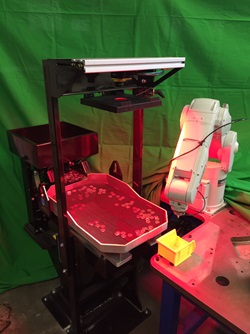

According to Parnello, the RR Floody Fully Integrated Flexible Feed System — a complete package with the Mitsubishi Electric robot and Cognex vision system joined by a high quality Graco G-Flex 1500 Feeder, and all fully integrated in-house and “85% ready to go out of the box” — promises to offer significant benefits for manufacturing operations concerned about the impact of shortening product cycles.

“The traditional bowl feeder will probably never go away, but for those facilities looking for a solution to the expensive downtime caused by the need to frequently retool traditional feeders, flexible feeders offer enormous advantages,” he said. “And with the quality of the Cognex/Mitsubishi Electric combination — and RR Floody’s ability to bring them together optimally and also integrate the flex feeder into the specific customer application — we think that this can be an extremely effective and cost-saving solution for many facilities.”

In addition, Parnello notes, its not only robots, but also many other Mitsubishi Electric products that are designed to work closely with Cognex vision systems. That means that it’s fast and easy for manufacturers to select from Mitsubishi Electric’s broad line of automation products to add other capabilities to the new RR Floody Flexible Feed System. HMIs for example.

“Customers can add an HMI to the system and immediately see the camera image display right on the screen, without a PC,” he explained. “That’s just one of the ways that customers can choose to customize, expand, and add to the effectiveness of this powerful solution.”

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product