Encoders use different types of technologies to create a signal, including: mechanical, magnetic, resistive and optical – optical being the most common.

What IS an Encoder?

Contributed by | Encoder Products Company

A VERY basic introduction

If you Google encoder, you'll get a vast and confusing array of responses. For our purposes,encoders are used in machinery for motion control.

Encoders are found in machinery in all industries. You'll find encoders used in cut-to-lengthapplications, plotters, robotics, packaging, conveying, automation, sorting, filling, imaging, and many, many more. You may have never noticed them, but they are there. In this blog post, we will give you a very basic introduction into what an encoder is, and what it does.

What IS an encoder?

Simply put, an encoder is a sensing device that provides feedback. Encoders convert motion to an electrical signal that can be read by some type of control device in a motion control system, such as a counter or PLC. The encoder sends a feedback signal that can be used to determine position, count, speed, or direction. A control device can use this information to send a command for a particular function. For example:

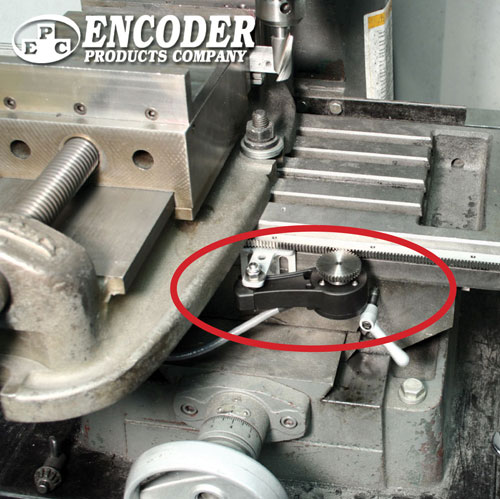

- In a cut-to-length application, an encoder with a measuring wheel tells the control device how much material has been fed, so the control device knows when to cut.

- In an observatory, the encoders tell actuators what position a moveable mirror is in by providing positioning feedback.

- On railroad-car lifting jacks, precision-motion feedback is provided by encoders, so the jacks lift in unison.

- In a precision servo label application system, the encoder signal is used by the PLC to control the timing and speed of bottle rotation.

- In a printing application, feedback from the encoder activates a print head to create a mark at a specific location.

- With a large crane, encoders mounted to a motor shaft provide positioning feedback so the crane knows when to pick up or release its load.

- In an application where bottles or jars are being filled, feedback tells the filling machines the position of the containers.

- In an elevator, encoders tell the controller when the car has reached the correct floor, in the correct position. That is, encoder motion feedback to the elevator's controller ensures that elevator doors open level with the floor. Without encoders, you might find yourself climbing in or out of an elevator, rather than simply walking out onto a level floor.

- On automated assembly lines, encoders give motion feedback to robots. On an automotive assembly line, this might mean ensuring the robotic welding arms have the correct information to weld in the correct locations.

In any application, the process is the same: a count is generated by the encoder and sent to the controller, which then sends a signal to the machine to perform a function.

How does an encoder work?

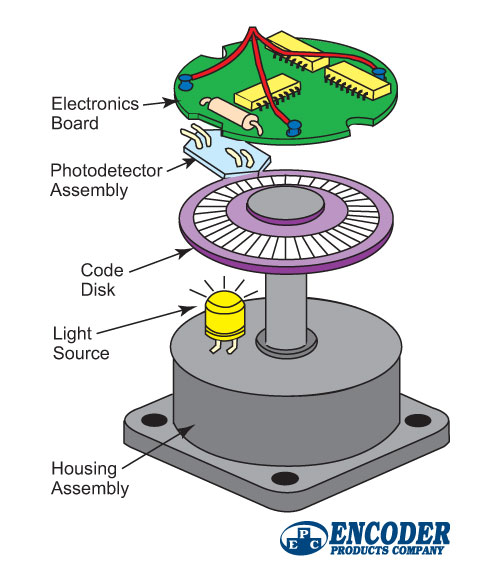

Encoders use different types of technologies to create a signal, including: mechanical, magnetic, resistive and optical – optical being the most common. In optical sensing, the encoder provides feedback based on the interruption of light.

The graphic at right outlines the basic construction of an incremental rotary encoder using optical technology. A beam of light emitted from an LED passes through the Code Disk, which is patterned with opaque lines (much like the spokes on a bike wheel). As the encoder shaft rotates, the light beam from the LED is interrupted by the opaque lines on the Code Disk before being picked up by the Photodetector Assembly. This produces a pulse signal: light = on; no light = off. The signal is sent to the counter or controller, which will then send the signal to produce the desired function.

What's the difference between Absolute and Incremental encoders?

Encoders may produce either incremental or absolute signals. Incremental signals do not indicate specific position, only that the position has changed. Absolute encoders, on the other hand, use a different “word” for each position, meaning that an absolute encoder provides both the indication that the position has changed and an indication of the absolute position of the encoder.

For more detailed information on how encoders work, see WP-2011: The Basics of How an Encoder Works, and the Encoder Basics section of EPC's Installation and Wiring Guide.

If you have questions about how an encoder will work in your specific application, contact us. When you call EPC, you speak to engineers and encoder experts who can answer all your questions.

Call today, and you could have your encoder solution in a matter of days.

About Encoder Products Company

Encoder Products Company (EPC) is a leading manufacturer of premium rotary incremental and absolute encoders used for motion feedback. Our encoders are available worldwide to OEMs, MROs, End Users, Service/Repair Organizations and others through a qualified network of electrical, motion control, and industrial distributors. The Americas Division of EPC, located in Sagle, Idaho, USA, is headquarters for worldwide manufacturing and encoder research and development. To service and support regional markets, EPC also operates manufacturing facilities in Europe and Asia.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Encoder Products Company

At Encoder Products Company, we specialize in the encoders that provide you with motion feedback. EPC has been a leading designer and manufacturer of motion sensing devices for more than 50 years, we understand that each industrial automation application is different, and you need encoders that fit the needs of your applications. Our encoders are highly configurable, offer an array of shaft or bore sizes, output types, connector types, mounting options, and resolutions as high as 65,536 CPR.

Other Articles

SCARA Robot Sorts Recyclables Using a Simple Conveyor Speed Feedback System

Talking PACK EXPO with Encoder

Tru-Trac™ Keeps Frankenstein Alive

More about Encoder Products Company

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product