In this section, well discuss how to present the idea of automating your production with your workforce, and how to help diminish fears of working with robots.

Getting Started with Collaborative Robots - Part 3 - Get the team on board with robots

Contributed by | Robotiq

There are a lot of misconceptions when it comes to robots. In fact most people think that if a robot enters a plant, a lot of people will lose their jobs. But the goal of robots is not to eliminate jobs, instead it is to eliminate monotonous and repetitive tasks, so workers can focus on more value added tasks, boosting productivity and prosperity for the company. In all the plants where we’ve seen automation happen, management has not cut jobs, but rather transferred personnel to other work that requires more dexterity and more “thinking” than repetitive redundant tasks. Remember those tasks that were difficult to automate, for example logic-based or fine assembly tasks? This is where people end up working.

So, the integration of robots does not cause job loss, rather it creates a shift in labor to other tasks on the production floor. Your main goal is to produce more with the robot, so you will need more people down the line to handle that increase in production. You will end up moving these employees to jobs that are more stimulating for them. The end result will be employees that are more motivated about their work!

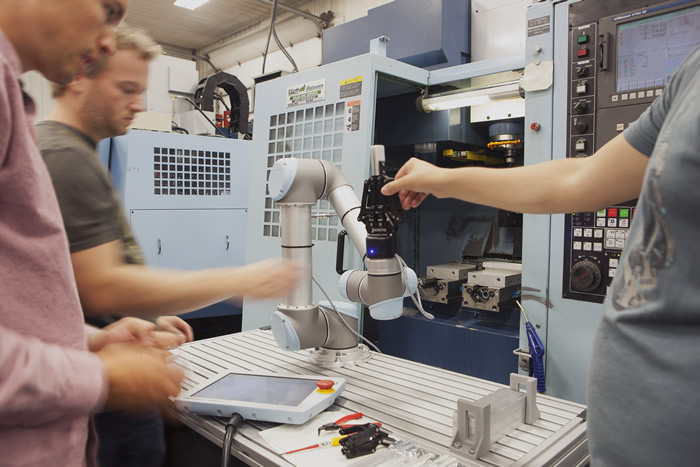

To ease the integration of robotics on the production floor, you should present the many benefits that robots will bring to the workforce on a daily basis. This will help them to understand that the robot is just like any other tool in their arsenal and give them reasons, as well as the confidence to accept this new co-worker.

Ergonomics

Redundant, fast paced or high endurance applications tend to be physically hard on workers. In these types of situations the risk and incidence of workplace injury is high. Being able to avoid this risk of injury helps workers to see the robot in a positive light, especially if they are transferred to something safer.

Boring non value added jobs

Tending a machine all day long is not very motivating work. However, doing setups, quality inspections, and programming robots are tasks that are more stimulating and safer for your employees. So while the production is running, you are literally adding value to your product. Also using robots allows you to keep your production running at a consistent pace.

In fact, in most cases, the fear of robots before the first application is deployed is readily transformed after the robot is installed and people realize how the robot can help them to enjoy their work more. Many robots become part of the team, so much so, that some receive nicknames!

If you’d like to explore this concept further, here is a page with videos you can watch from real-life companies that went the collaborative robot way.

ROBOTIQ MAKES TOOLS FOR AGILE AUTOMATION

Robotiq’s mission is to free human hands from tedious tasks so companies and workers can focus where they truly create value.

Robotiq’s mission is to free human hands from tedious tasks so companies and workers can focus where they truly create value.

Our grippers and sensors enhance robot application flexibility and integration simplicity.

Our products are sold and supported in more than 30 countries, through a network of highly capable channel partners.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product