With a combination of high torque density and precision motion, compact stepper motors provide full 360° of correction for instrument tilt.

Contributed by | Micromo

Geophysicists depend on seismometers to monitor earthquakes generated by the motion of the tectonic plates that form the Earth’s crust. In order to function, the instruments need to be leveled prior to operation. That’s easy enough for a device deployed on dry land, but when it comes to seismometers placed on the ocean floor thousands of feet below the surface, the process gets a bit more challenging. To solve it, Nanometrics Inc. (Kanata, Ontario) combines sophisticated gimbals and microprocessors, along with ultra-reliable, efficient motors from MICROMO (Clearwater, FL).

CASE FACTS

Organization: Nanometerics Inc, Kanata Ontario

Industry: Precision Instrumentation

Country: Canada

Challenge: In order to function, the instruments need to be leveled prior to operation. Not easy when it is thousands feet on the ocean floor.

Solution: To solve it, Nanometrics Inc. (Kanata, Ontario) combines sophisticated gimbals and microprocessors, along with ultra-reliable, efficient motors from MICROMO (Clearwater, FL)

Results: A Trillium 240 was deployed at the South Pole and it operated perfectly. The turn-on temperature was -58°C (-136°F). The system temperature settled eventually to -50° C (-122°F) and stayed there for a long period of time. The motors turned on and did exactly what they were supposed to do.

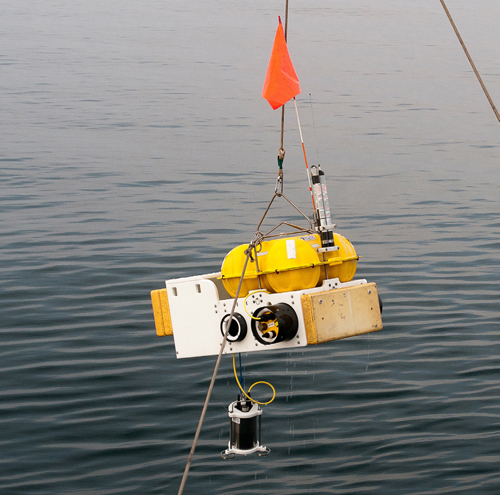

Figure 1. To deploy the Trillium OBS (black cylinder), users attach the seismome- ter to a metal sled that carries it down to the sea floor. At the end of the exper- iment, the transponder signal triggers the release of ballast and the instrument floats to the surface. (Courtesy of Nanometrics Inc.)

At its simplest, a seismometer consists of a frame that moves with the underlying rock, a pendulum that essentially acts as an inertial mass, and electronics that track the displacement between the two. Nanometrics seismometers feature three inertial masses aligned on orthogonal axes to allow the instruments to measure in three dimensions.

The frequencies of interest to geophysicists extend from 100 Hz all the way down to below 1 mHz. A classical pendulum consisting of a weight hanging on a string always centers itself thanks to gravity, but is not suitable for measuring ground motion at very low frequencies. Broadband seismometers typically use some form of inverted pendulum instead, in which a spring, rather than gravity, provides the restoring force. Inverted pen- dulums aren’t self-centering; they need to be balanced; hence, the need for leveling.

Ocean-floor seismometers operate several kilometers below the surface, far deeper than practical for cables. Instead, the battery-powered instruments operate in isolation for the duration of an experiment, which can last as long as a year. After, they’re brought back to the lab for analysis—and only then do users know whether they worked. “That can be long after they’re deployed,” says Jeff Potter, director of marketing at Nanometrics. “The ships that deploy and retrieve ocean bottom seis- mometers are very costly, so you need to be absolutely sure the sensor will perform perfectly every time.”

Reliability is only the start of the requirements. Re- searchers place ocean-bottom seismometers by attaching them to a weighted sled and letting them sink to the ocean floor, a process that can take hours. At the bottom, they land on an arbitrary, often muddy sur- face with unknown local topography, and the leveling process begins. In the case of seismometers on dry land, the installer can ensure that the instrument is physically level but the system may require periodic adjustments to compensate for thermal cycling. For undersea ap- plications, conditions tend to be thermally stable, but mechanical tilt can be both extreme and dynamic. As a result, the mechanical leveling system needs to be able to right the sensors even when the instrument comes to rest upside-down.

The three axes of the Trillium Compact OBS (seafloor) and Compact All-Terrain (dry land) are rigidly attached to each other so that the system levels the platform as a whole. To provide a broad range of adjustment, Nano- metrics mounts the seismometer in a motorized gimbal. The inner frame rotates the instrument around its own axis, then the outer frame rotates the instrument with respect to the case. Accelerometers on the seismometer and case determine the degree of tilt, then the micro- processor commands the motors to adjust the position as required, fully leveling the system in 20 minutes or less.

The positioning mechanisms need torque in order to level the instrument payload. Normally, the easiest way to increase torque is to choose a larger motor or add a reduction ratio with a gearmotor. The problem the engi- neering team faced was that the design was space con- strained, so simply choosing a larger motor wasn’t an option. “If we’d gone from a 10 mm-diameter-motor to a 15-mm motor, the instrument immediately would have gotten a couple of centimeters bigger in diameter,” says Nick Ackerley, a senior scientist at Nanometrics. A larger instrument would require a larger sled in order to carry the device to the seafloor, increasing weight and costs, as well as dimension. “The ramifications go all the way up to the size of the boat that you’re using for your weeks-long cruise out at sea, and these boats can cost hundreds of thousands of dollars a day to book. [A small change in motor size] can make the difference between deploying 10 or instruments or 15 instruments on a giv- en cruise.” The team needed rugged, reliable, compact motors with high torque density, and MICROMO provid- ed the solution.

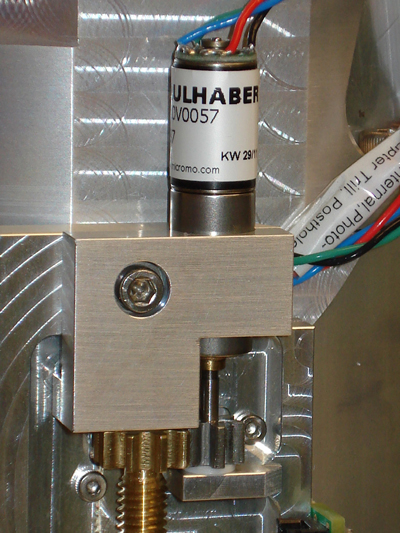

Figure 2. The leveling mechanism integrates a high-torque-density stepper motor and a gearbox to adjust the position of the instrument. (Courtesy of Nanometrics Inc.)

The design incorporates two stepper motors controlled by a microprocessor. The leveling algorithm uses the accelerometer readings to calculate the motor motions needed to level, but the final leveling result is checked using the seismometers themselves. Using a stepper motor for the motion task brings an important benefit of dependability. “It makes the control a lot easier to simply be able to command the instrument to a certain location,” says Ackerley. “We always check to make sure that the motor actually goes to the position we’ve ordered. Our algorithms are designed to deal with it if it doesn’t, but we’ve never seen it actually do anything but go to the position that is commanded.”

The design transfers motion from the motor to the gimbaled seismometer using a worm gear, which yields a more compact, robust design. The gear also offers stability, even under exposure to shock and vibration. Worm gears cannot be back driven, for example, which protects the gearbox load. Next, the design team need- ed to integrate the worm gear with the gearhead. One obvious method was to tie the two together with a set-screw, but the motor shaft is just 2 mm in diameter. “Fastening the gear to the shaft using a set-screw was not sufficiently reliable, especially given the very small screw that would have to be used,” says Ackerley. “We worked with MICROMO to develop a way to weld a gear directly onto the gearbox output shaft.” Receiving motors with a gear already integrated speeds and sim- plifies the assembly process for Nanometrics.

The company’s Trillium 120 and 240 models for dry-land operation also feature motorized levelers, but rather than positioning the platform as a whole, the motors adjust each pendulum individually. Using bubble levels, the installer can manually position the seismometer to within a few tenths of a degree of level. The additional leveling accuracy provided by the motors means the electronics aren’t working as hard to center the masses. This allows the instrument to measure signals at ex- tremely low frequencies, such as the natural resonances of the whole earth. “All of these instruments are using MICROMO motors, and they are doing very different jobs, says Ackerley. “In terms of size and torque for a given current and given volume, the MICROMO motors just keep standing out, so we are sticking with them.” Even on dry land, the seismometers must survive pun- ishing conditions. “A Trillium 240 was deployed at the South Pole and it operated perfectly,” says Ackerley. “The turn-on temperature was -58°C (-136°F). The sys- tem temperature settled eventually to -50° C (-122°F) and stayed there for a long period of time. The motors turned on and did exactly what they were supposed to do.”

MICROMO also supplies the motors with cable and con- nectors already integrated, decreasing scrap during the manufacturing process. “We found that by doing this assembly in house, we were damaging a small percent- age of the motors, so we felt it was better for everyone to let the experts take care of it,” says Ackerley. “In our latest generation of products, we’re specifying a welded gearhead on the output shaft and a cable at the elec- trical inputs, and furthermore, the welding has been redesigned to make it simpler to manufacture.”

Ultimately, MICROMO’s quality motors and value-added manufacturing have helped Nanometrics bring their rugged, reliable, low noise, high-sensitivity seismome- ters to market rapidly and economically. “Over the years we have collaborated closely with MICROMO,” says Potter. “Our relationship with MICROMO is not so much one of supply and demand, but a partnership.”

Figure 3. Ocean-floor seismometers like the Trillium OBS must be both rugged and reliable. (Courtesy of Nanometrics Inc.)

Inside the Solution

Seismometers capture transient phenomenon. If an instrument malfunctions, whether it’s at the bottom of the ocean or atop a polar ice cap, that data is lost forever. “You need to be absolutely sure the sensor will perform perfectly every time,” says Jeff Potter, director of marketing at Nanometrics. “Seismometers also need to be small and consume very little power when they level themselves, and that’s where MICROMO has helped.”

The leveling mechanism integrates the following devices:

- The AM1020-V-6-65, a in a 10-mm-diameter, two- phase stepper motor that provides a peak torque of 1.6 mNm. With 20 steps per revolution, and PRECIstep technology, the motor offers reliable, accurate motion, even in harsh environments.

- A 10/1 planetary gearbox provides a 256:1 reduction ratio in a 10-mm-diameter package.

About Micromo

For over 50 years, MICROMO (FAULHABER Group) has brought together the widest range of high quality, high performance linear and rotary motion solutions, decades of micro motion expertise based on dc motor technology and full service design, sourcing and manufacturing capability on a global basis to deliver benchmark motion solutions. Call MICROMO at 800-807- 9166 and let one of our Application Engineers, design a custom motion solution for your next application.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

FAULHABER MICROMO

Since 1961, FAULHABER MICROMO has partnered with OEMs to deliver high precision, high performance, custom micro motion system solutions to markets such as medical, robotics and automation in North America. FAULHABER MICROMO's tradition of innovation started decades ago in Germany. The groundbreaking invention of the FAULHABER coreless winding started it all for a market that produces millions of motors today. How can the FAULHABER MICROMO team help you deliver your next innovation to market first? Learn more about MICROMO's solutions for the most demanding applications, our diverse motion products and technologies, online ordering, Engineering and R&D teams, Clean Room Assembly, Machining Center and other services at our Clearwater, FL facility at https://www.faulhaber.com.

Other Articles

Walking naturally with artificial foot

Testing drive systems virtually - Simulink library for development and digital twin.

At least 60 million strokes

More about FAULHABER MICROMO

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product