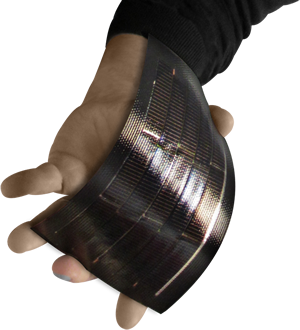

When you have the combination of high energy density and thin and flexible form factor, you can apply this solar material to anything with a battery that moves, can be carried, or worn.

Rich Kapusta | Alta Devices

What is your announcement?

What is special about Alta Device's technology that enables such a significant improvement for small unmanned aerial systems endurance?

How well does your technology work in low light or even indoor light conditions?

The material that Alta Devices uses is Gallium-Arsenide (GaAs). This material has excellent low light absorption properties, allowing it to convert light into electricity not only when the sun is shining bright in the middle of the day, but also early morning, and late evening when other materials have already stopped working. This property also gives it significant light harvesting capability even in indoor light conditions.

What about high temperature?

Is there any reason why we wouldn't put this on every battery powered UAV made?

Besides UAVs, what other applications are well suited for Alta Device's technology?

Are the materials used in the solar film rare or expensive to obtain?

- Gallium is a byproduct of the production of aluminium and zinc. Most gallium is extracted from the crude aluminium hydroxide solution of the Bayer process for producing alumina and aluminum. For semiconductor use, further purification is carried out using zone melting, or else single crystal extraction from a melt (Czochralski process). Purities of 99.9999% are routinely achieved and commercially widely available.

- Arsenic makes up about 1.5 ppm (0.00015%) of the Earth's crust, making it the 53rd most abundant element and is recovered mainly as a side product from the purification of copper.

- We use a GaAs wafer as a seed crystal for our growth, and since we can reuse the wafer 1000 times, the cost of the wafer is not a major contributor to our solar films.

- Finally, we only grow a 1 micron thin solar cell, so the amount of raw Gallium and Arsenic that we do consume for each film is very small.

How does the cost of your film compare with other films and with traditional solar modules?

The answer to this question is purely a function of scale. Today, our costs are high as we are operating a small pilot line in Sunnyvale, CA, but as we scale, this cost will reduce and ultimately can be competitive with any other solar material produced today.

The answer to this question is purely a function of scale. Today, our costs are high as we are operating a small pilot line in Sunnyvale, CA, but as we scale, this cost will reduce and ultimately can be competitive with any other solar material produced today.

RICH KAPUSTA, VP OF MARKETING

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product