Users who have never programmed anything at all before can set up our robot, type their first command and immediately see a result without requiring an integrator or consultant to install and program the robot. Additionally ST Robotics follows up with unlimited technical support.

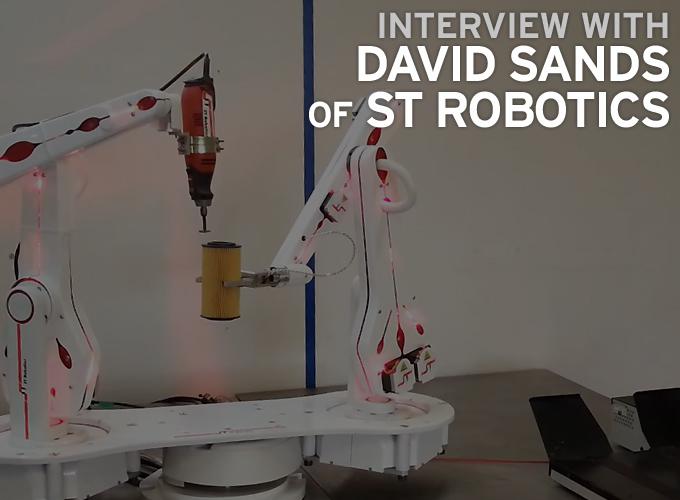

David Sands | ST Robotics

Tell us a little bit about ST Robotics.

Back in the 80s my (then) company Cyber Robotics was making educational robot arms, and we also received many inquiries for professional applications. This alerted me to the need for an industrial quality bench-top robot arm. Most of the arms available at that time were designed for manufacturing, i.e., large robots for high volume use in the automotive industry. I needed a robot that small companies could afford and we began the development. I then formed Sands Technology in the mid-80s to manufacture small robots, and about 10 years later, changed the name to ST Robotics.

ST Robotics utilizes technology based on Stepping motors as opposed to the more common DC Servo motors. Can you give us some details on the differences in motors and why you have chosen the Stepping motors?

Stepping motors are much cheaper than servos. We use micro-stepping bipolar drives and high drive voltages to pile in the power at a much lower cost.

Stepping motors may not compete on raw power, speed, or power-to-weight ratio, but most of robotics is about short complex motions. In these situations, steppers are actually better because they deliver very high torques at lower speeds. And, being digital motors, they are much easier to control.

ST Robotics sells its Robots strictly through the Internet as "Boxed Robots". Why have you chosen this route and how is it worked?

In terms of the route and how it's worked, our business model is based on the long tail concept which is a phenomenon with product sales. It basically states that if a product is needed by everyone and is cheap, then millions are produced, purchased, and available in every store. But when the product gets more specialized and the number of potential customers become rarified, the sales volumes gradually taper, and it gets more and more difficult to reach those customers through conventional means. The Internet changes all that.

R12-firefly, low cost 5-axis 500mm jointed (articulated) robot arm.

Today's users know to search for the robot they require and they find us. As a matter of fact, ST Robotics comes up at the top of the first page for searches such as 'low cost industrial robots'.

Can you describe the setup process for a company once their ST Robot arrives?

The user takes out the robot and sets it up on the bench along with the controller. He then loads up our CD and finds the detailed manuals. These tell the user how to connect everything up and start making the robot move.

Users who have never programmed anything at all before can set up our robot, type their first command and immediately see a result without requiring an integrator or consultant to install and program the robot. Additionally ST Robotics follows up with unlimited technical support.

What type of applications are you typically seeing your Robots being used in?

I get this question a lot and it's the most difficult to answer. It's kind of like, "what do computers get used for?" only worse, because though the industries types are standard, the applications seem to be mostly custom.

Though ST Robotics robots are designed for standard low payload applications, they are rarely the kind of industrial application one would expect such as press feeding or molding machine access.

Applications that we see include passing a health monitor over a patient, repeat testing of contact-less smart cards, handling radiochemicals, pushing buttons on radio telephones for automated QC, testing ATMs, and many more.

Your Robot have become very popular amongst educational facilities for use in classroom education and training. Why do you think that is?

Our target market was meant to be professional so we never expected to sell into education. For one thing our robots "just work" (to use a popular phrase) so you don't get to learn 'how' they work. We now realize that students need to learn how to practically use robots. It turns out that the simplicity of ST Robotics software and the ease of getting the robot to actually do something makes it an ideal educational tool. Plus the instructors tell us that the extensive, yet easy-to-learn tutorials help to develop a successful curriculum.

Tell us about the "GoForth Robotics Program" STRobotics sponsors.

Robotics for kids always ends up with boys building wheeled vehicles. But ST Robotics GoForth Robotics Program is more than that. Our kit comprises a CAD system, mechanical parts based on the Meccano/Erector-set (that many people thought was long gone but is still popular) an ARM micro-controller and low cost servos. With these, anything robotic can be built - it could be a moving face or a dancer.

We want the girls to be involved. Our program encourages team work. One kid might be the manager, one does the CAD design, one is good at assembly, and yet another with the software. The software is the same RoboForth we use in our robot arms (though a lighter version). So the young students can immediately test any small part and follow a building-block approach with the mechanics and software together, building confidence as well as robots.

There are a lot of misconceptions about Forth. Most software these days is written in C which is actually just as old as Forth. But C is not kid-friendly. Forth loves hardware. The youth can build a bit, type some Forth command and see it work right away, then move on.

What do you see in the future for STRobotics?

Our affordable robots are selling in increasing numbers all around the world, to companies who are just moving into robotics for the first time.

At the same time we are taking on distributors for emerging markets such as Asia, China, India, and will possibly license the designs for local production. The background Internet sales will continue to increase and meanwhile we continue to develop new products.

About ST Robotics

ST Robotics provides professional but affordable, easy-to-use, ready-to-go boxed robots. ST aims to provide robots that are easy to set up and use, easily programmed by any individual regardless of experience, fast, accurate and reliable, and easily affordable by any industry small and large, testing and R&D departments, and laboratories.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product