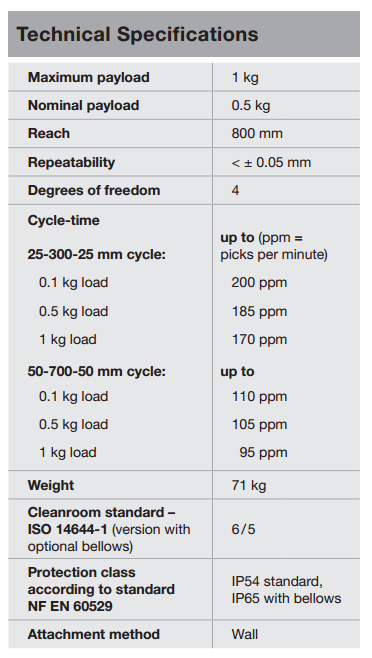

The new TP80 fast Picker robot from Stäubli Robotics introduces innovative, high-speed four-axis kinematics for pick and place applications. This high-speed robot achieves peak rates of well over 200 picks per minute.

David Arceneaux | Staubli

Earlier this year Staubli released the TP80 Fast Picker, tell us a little bit about the TP80?

The TP80 robot is the “latest innovation in picker technology” and is extremely fast (200+ parts/min. continuous). The robot is designed to handle operations with small parts (1 kg and under) and is particularly well-suited for applications requiring very high speed pick and place of parts.

What are the target markets or applications for the TP80?

The TP80 is ideally suited for the food, pharmaceutical, PV, automotive, and any industry requiring high speed pick and place for assembly, sorting, picking, packing, etc.

What differentiates the TP80 from other high speed robotic systems?

The main benefits of the TP80 are its high speed innovative kinematics and wall mountable configuration which does not require a large mounting weldment such as for Delta robots. This means that the robot does not have to be mounted over the product offering integration many benefits. It also has a fully enclosed rigid structure with all cables and lines running through the inside of the arm, and a larger working envelope with higher repeatability throughout its working range.

How do you see this new technology changing the industry?

Faster speeds, lower cost, and higher reliability.

What are the most common applications for the TP80 today?

The TP80 is specifically designed for any application requiring high speed pick and place of small parts.

How has this new technology been received by potential customers already using competitive products?

End users and integrators are raving about this new technology stating that it is; easier to integrate, has less moving parts which means higher reliability, costs less than Delta robots. In addition it is not situated over the conveyor/parts simplifying integration and offers easy access in the event of service needing to be done.

Is the robotics industry growing at a fast pace or is it just business as usual?

According to the Robotics Industry Association (RIA – www.robotics.org); “North American robotics companies sold more industrial robots in the second quarter of 2012 than any previous quarter in history”.

Obviously this is a positive sign and we see the robotics industry potentially continuing this growth trend for several years now due to the surge of manufacturing companies reshoring their operations in the USA.

About Stäubli

About Stäubli

Stäubli is a mechatronics solution provider with three dedicated divisions: textile machinery, connectors and robotics. With a workforce of over 3000, the company generates a yearly turnover surpassing 1 billion Swiss francs. Originally founded 1892 as a small workshop in Horgen / Zurich, Stäubli today is an international group with its head office in Pfäffikon, Switzerland.

The content & opinions in this article are the author’s and do not necessarily represent the views of RoboticsTomorrow

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product